When creating all kinds of structures from plasterboard sheets, for example, when installing sheets on a ceiling frame, it is important to make the ends even. In the case of factory-made material, there is no such problem, since the sheets are sold with a ready-made chamfer, and the end is perfectly smooth. Self-cutting only in rare cases leaves behind straight ends. This is not a matter of some kind of aesthetic appeal; rather, it is a necessary measure. Firstly, the gaps between individual layers should not differ from each other, but sometimes extra millimeters simply do not allow the material to fit properly into the right place. Just in this case, you should use a plasterboard edge plane.

Best Plastic Sanding Planes for Drywall

This type of tool contains knives in the form of a perforated plate, like a kitchen grater, which allows you to rip off the end of the gypsum sheet to a flat plane (initially it comes with a bevel). This promotes smooth joining and beautiful jointing.

TOPEX 250 mm 11A411 - for two-handed operation

This is the best plane for drywall when large volumes of peeling are required and a separate person is involved in this, and other craftsmen can already take the finished sheets and install them. It is advisable to install the sheet on the edge and fix it in order to fully and quickly peel. The tool is designed to be held with two hands, which provides optimal pressure on the roughing surface and a better result. To do this, there is a D-shaped handle at the rear and a high stop at the front.

- additional intermediate posts in the planer design increasing its strength;

- the high emphasis on the front allows full pressing with the second hand;

- Suitable for wood, plastic and plaster;

- sole length 250 mm ensures high performance;

- the ergonomic shape of the handles fits well in the hands;

- knives made of tool steel;

- weight 160 g is easy to work with and carry the tool on your belt.

- cost from 470 rubles;

- no belt clip;

- The faceted handle presses the palm with a strong grip.

MATRIX 879065 - for one hand

This type of planer for drywall is the best due to its compact size, which is important for a master working alone. With its help, you can hold the sheet with one hand and quickly align the end for joining with the other. The length of the plane is 140 mm, so it is convenient to carry it on your belt and manipulate it even on short workpieces.

- cost from 200 rubles;

- durable body;

- there is a small stop for additional pressure with the second hand;

- capable of processing even fiberglass and gas silicate blocks;

- weight 140 g;

- 42 mm cutting surface width facilitates fast processing;

- compact dimensions 160x120x50 mm are optimal for storage and transportation;

- quick replacement of the working blade;

- removal of chips through special holes;

- with the proper experience of the craftsman, it is even suitable for chamfering and finishing edges.

- for a person with large hands it may be small (be careful when ordering online, you just need to pick it up and look);

- on sheets with soft plaster (etc.) it lifts the paper when cut.

What are they?

There are 2 types of tools on the market. Groups have structural differences and perform specific tasks.

- Kromočny. Necessary for aligning edges, chamfering and cutting at a certain angle (mostly 45). If you do not carry out all the necessary manipulations, the decorative finishing of the joints will be deformed in the future. The body is made of plastic or metal. The latter has received an increased service life and will be relevant for those who work with it a lot. To increase service life, a powder anti-corrosion coating is applied. There are 2 trapezoidal blades installed at the bottom. The solution allows you to achieve the required cutting depth through alignment. The points are secured with a bolt. The simple and functional implementation of the fastening ensures quick replacement of dull knives and setting the required angle. The availability of such functionality depends on the manufacturer. The cutting part does not need to be sharpened after each use. Just turn it over and continue using it. The dull part is renewed over time. Unified blades make it easier to purchase components. All you have to do is go to the nearest specialized point. The top of the body received 2 handles. They are either wooden or plastic. One of the handles is installed at the front and acts as a guide. The second is located at the rear and is used to move the gun. For professional activities, it is better to give preference to the first option. The final result and how quickly the performer gets tired depends on how it lies in the hand. For home use this is not important. The main thing is that it fits comfortably in your hand and is durable. A universal and functional tool that, provided the blade steel is of the proper quality, can be used to work with plastic and soft wood. In most cases, small surfaces are treated with this product. Depending on the manufacturer, the kit may include a side stop, a stopper and a blade sharpener.

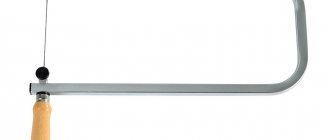

- Rip-off. The edge of the plasterboard sheet (GKL) obtained by cutting is curved. Such an element is difficult to dock with the main structure. The main task of a roughing plane is to correct the situation that has arisen. It is used to grind the edges of the edges, which are joined at an angle of 90. The basis is a steel frame, on which the remaining components of the structure are fixed. It is installed in a reinforced plastic or wooden case. In this way, an ergonomic shape is achieved. There are models with a completely plastic frame. They have a short service life. Designed for use at home if no more than 10 sheets need to be processed. The professional construction tool has a steel body. This increased the service life, but had a negative impact on the cost. A special canvas is placed below to interact with the material. Outwardly, it resembles a kitchen grater. It has many holes with protruding sharp edges. There is an arched handle at the top. This solution makes it easier to interact with the tool with one hand, making it possible to hold the plasterboard. There are models similar to a cheese grater. They are characterized by a small blade mounted on a regular rod handle. It is relevant for processing small areas. Using a plane will not cause any difficulties. It is enough to hold the drywall and gradually remove all surface defects. You should be careful when interacting, as the material is fragile. Wood processing is allowed.

The best edge planes

To evenly cut a sheet of drywall, edge planes are used, which are distinguished by thin protruding knives. Some models are capable of cutting at different angles, if this is required for a tighter joint.

FIT 15025 - the most common model

This is the most famous edge plane that every second drywaller has. It is the best due to the presence of two knives and the ability to cut at angles of 22.5 and 45 degrees. There is also a classic 90 degree cut. For holding, a protrusion is provided that corresponds to the shape of the back of the hand when grasping it.

- there is an adjustment of the cutting depth depending on the thickness of the plasterboard sheet (9.5 / 12.5 / 15 mm);

- variable position of the knives by turning the pressure wheel;

- blades made of tool steel;

- light weight 280 g;

- streamlined body shape is comfortable to wear and grip;

- long service life with the ability to replace broken knives.

- cost from 390 rubles;

- may periodically tear out the paper with the first knife (users have come up with the idea of swapping the pressure plate of the first knife and the blade, which eliminates this problem);

- plastic fasteners.

Stanley STHT1-05937 - the choice of a true professional

Real craftsmen who have to process 20 or more sheets of drywall per day prefer to use the best plane from Stanley, which is highly accurate and reliable. The tool has a comfortable handle made of thick rubber with cutouts for the palm, which makes it easier to hold firmly.

- compact dimensions of 200x60 mm are convenient for one-handed operation and storage on the belt during sheet installation;

- adjustable blade height allows you to work with different sheet thicknesses (from 6.5 to 13.5 mm);

- the body has a metal corner that serves as a guide, which prevents the tool from moving to the side while making a cut;

- the knife can be easily replaced with a new one by unscrewing the pressure wheel;

- good visibility for the cutting area master;

- trapezoidal knives are stronger than regular knives and are available for purchase at any hardware store;

- high-quality assembly with a cast base helps reduce vibration during operation.

- cost about 900 rubles;

- There is no loop for hanging on a belt.

What is used when working with this finishing material?

Purchased tools and other components for performing work are divided into several types. These can be special profiles, all kinds of devices, hand and power tools, meters, seals, etc. Let's look at them in more detail.

Metal profiles for finishing partitions and walls

There are guides (labeled UD and used to secure racks and frame rail guides for drywall) and rack-mounted (marked as CD and are the main rail used for installing drywall).

There are also narrowly focused ones:

- arched varieties that adapt to the desired configuration;

- guides intended exclusively for doorways to which entrance systems are attached (impregnated with zinc to prevent destruction by corrosion).

By combining all the components, fastening them with a special material, you can ultimately get a reliable, durable frame that will withstand heavy loads, including all gypsum cladding.

To work with drywall you need to have:

- direct hangers are rectangular plates that act as the main elements of a frame intended for gypsum sheets, and are also used to connect load-bearing coverings to frame posts;

- anchor hangers - used as a base for drywall when finishing the ceiling, they connect the base to the ceiling;

- two-level connectors - necessary in the process of connecting frame slats crosswise;

- connectors for CD guides (“crabs”) - used to connect the ends of the profile in a single-level plane;

- profile extensions - they extend the frame slats, are installed inside the profiles and are fixed with self-tapping screws;

- corner connectors - have a T-shape, making them excellent for perpendicularly connecting a profile to another rail.

Required Tools

When working with sheets, you cannot do without:

- screwdriver - allows you to fix the frame in the right place;

- powerful hammer drill - used to firmly secure the frame to the surface of the wall, ceiling, floor;

- electric drills;

- angle grinders or “grinders” - in order to cut profile parts and cut off unnecessary parts of the structure;

- circular saw or jigsaw, which can be used to cut drywall. For small volumes - with a hand saw for drywall or a construction knife;

- electric scissors - used in the process of cutting metal (if there is a need to make a large structure equipped with plasterboard panels);

Among the hand tools are:

- hammer;

- knife for working with drywall;

- profile punch;

- knife-saw;

- plane (regular and edge plane);

- needle roller for giving radii to sheets.

Devices for working with GLK sheets

The following devices will simplify and speed up the installation process:

- portable handles - curved steel handles that are used to carry sheets;

- belt for installation;

- building level;

- tape measure - for accurate measurements;

- a stop product, which is a special lever with a lock, thanks to which you can hold the panel in the desired position (often vertical);

- a device designed for lifting sheets;

- pencil/marker and corner;

- chop cord.

Important! In order for the work to be carried out efficiently and as accurately as possible, you need to use only high-quality components and tools. This will ensure long life and reliability of the installed structure. Also, do not forget that the frame plays a major role in the gypsum finish.

Also, do not forget that the frame plays a major role in the gypsum finish.

Therefore, he needs to pay special attention

Best Metal Sanding Planes for Drywall

Due to the greater mass and metal sole, such a tool allows you to quickly obtain an even end for joining. These planes are distinguished by their increased strength, which is especially important for everyday use.

SANTOOL 250 mm - the most convenient

This is the best metal drywall planer for ease of holding. Its main handle has two bends that completely correspond to the shape of the user’s clenched hand.

There is a stop at the top of the handle to prevent the tool from slipping out during intensive work. The second handle is made in the form of a stop and is covered with dimples, which increases the reliability of the grip. Tilt of the stop forward makes it easier to set the stroke.

- Full metal body, protected from cracks when dropped;

- the oblong base is fastened with an additional jumper to increase rigidity;

- the sole length of 250 mm allows you to remove a large layer at a time, which increases productivity;

- for the exit and accumulation of chips, there are compartments at the top that collect them so as not to fill the cutting line and not block the view of the master;

- the knife can be replaced by unscrewing the screw on the front of the housing;

- weight 300 g does not make work difficult;

- small dimensions 250x110x90 mm;

- does not deform during everyday use.

- cost from 660 rubles;

- there is no fastener for hanging on the master’s belt;

- the handle is plastic and slips a little in sweaty hands;

Due to the increased length of the tool and holding it with two hands, additional fastening of the drywall sheet is required during stripping.

Best models

The rating is based on customer reviews.

STANLEY FatMax Exo

Country of origin: USA. Model of a mounting knife with a trapezoidal retractable blade. Its maximum length is 6.3 cm. Blade thickness is 0.65 mm. The cutting edge is located on both sides. The back of the handle has a compartment for storing accessories.

The shape of the knife has a slight bend. It has comfortable handle ergonomics. There are rubber pads on the top and bottom of the handle. The front part of the handle has a thickening. It strengthens the structure and prevents the blade from breaking under strong lateral pressure.

- increased strength;

- light weight;

- comfortable handle;

- versatility.

- No deficiencies identified.

"Bison" 09225

Country of origin: Russia. The model has a retractable design with a mechanical lock. The width of the canvas is 18.7 mm. The knife can be used to cut drywall, plastic, linoleum and roofing materials. The blade has a two-edged sharpening. The body of the product is metal. It has clips for attaching to a belt.

- robust construction;

- comfortable handle;

- versatility;

- double sharpening at the end of the cutter;

- increased blade strength.

- No deficiencies identified.

Olfa Ol – RTY – 1/G

Country of origin: Japan. The model belongs to special cutting knives and has a round blade. The blade material is tungsten. Blade thickness – 28 mm. The knife is designed for cutting drywall, fleecy materials, leather, wallpaper and other materials.

The model has a comfortable handle. It is adapted for left and right hands. The design has a hole for installing a device for cutting parts according to a template.

- increased strength;

- comfortable handle;

- sharp cutter.

- No deficiencies identified.

BRAUBERG "Professional"

Country of origin: China. The universal knife model is a professional tool. The product has a metal body, an ergonomic handle with anti-slip rubber inserts.

The case has a hole for installing a mount for hanging the tool on a belt. The knife set includes 5 blades of varying thicknesses, which can be easily replaced if necessary.

- versatility;

- convenient design;

- stylish design;

- robust design.

- No deficiencies identified.

Gross 78882

Country of origin: Germany. The model has a retractable trapezoidal blade. It has double-sided sharpening. Working blade length – 60 mm. The handle is equipped with anti-slip pads. The Gross 78882 knife is considered one of the safest.

- ease of blade replacement;

- reliable fixation;

- anti-slip handle.

- No deficiencies identified.

Roughing and edging plane for drywall: how to make it yourself

Drywall is one of the most popular and frequently used building materials for interior decoration. With its help, you can perform a huge number of repair and construction tasks, getting excellent results at a relatively low price. But despite the fact that gypsum board is very easy to use, its installation and processing also requires certain skills and a set of tools. For example, to create smooth seams and joints without gaps, you will need an edge or roughing plane for drywall. Let's figure out how to use this tool, what its features are and how to make a planer for gypsum boards with your own hands.

Purpose of a planer for gypsum boards

This tool is indispensable when processing plasterboard sheets. Since gypsum board consists not only of thick cardboard, but also of very fragile gypsum material, the edges of these sheets often crumble or chip. It is in this case that they have to be processed with a special plane for drywall.

In addition, in order to properly seal the joints with putty when facing gypsum plasterboard walls and ceilings, the edges at the junction of the sheets must be chamfered at an angle of 45 degrees. This creates a recess that is filled with a special putty compound, and in the future there will be no bulges or cracks on the seams.

In principle, sandpaper can be used to process the edges of a sheet, but its use will not give such a perfectly smooth and clear edge as when using a plane.

Processing seams and recesses from self-tapping screws ↑

After completing the installation of the plasterboard sheets, the joints of the sheets should be processed and the recesses from the screws should be filled with putty. For joints, a gypsum mixture is used, which, when dried, forms a very durable material. Chamfered edges must be primed.

A reinforcing mesh 80-100 mm wide is glued to all joints with the factory edge. In a situation where one or both edges of the sheet are chamfered, the mesh should be cut lengthwise and not allowed to go out of plane. If in this case you use a reinforcing mesh of normal width, you will have to putty the entire surface with a layer 1-2 mm larger.

About 60% of the recess volume is filled with the first layer of putty, then the mesh must be immersed in the putty and smoothed. At the end, the remaining volume of the recess is filled.

The recesses from the self-tapping screws also need to be filled with putty; to do this, you need to move the spatula in different directions to fill the recess with putty. As it dries, it shrinks a little, which is normal. The final treatment of the recesses is carried out with finishing putty.

Kromochny

An edge plane is used for chamfering, processing the edges of gypsum boards, and also for performing more even cutting of gypsum boards at the desired angle (most often 45 degrees). The blades of such a tool have a trapezoidal shape and can be shifted, which allows you to process the edge to a depth of 2 to 8 mm.

- Plastic or metal body with handle.

- Tension screw for fixing the blades.

- Planing blades installed not in the sole of the plane, as in the familiar carpentry tool, but on the side.

A standard edge plane is designed to bevel at an angle of 45 degrees. If necessary, you can find a tool for shaped chamfering when creating curved structures.

A quality edge plane can be used when working with softwood and plastic.

Blades

The blades of planes for processing drywall are usually made of alloy steel and have high-quality factory sharpening. Therefore, the cutters serve for a long time and without failure.

How to choose the right blade?

In most cases, edge planes use trapezoidal blades. Choosing the right blade depends on the brand and model of the plane. They are not expensive and are always freely available. In addition, there is always the opportunity to choose universal cutters, which are much cheaper than branded ones.

How to sharpen a blade and does it make sense?

Drywall is a soft material that is easy to process. Therefore, factory-sharpened blades last a long time. If chips or burrs occur on the surface being treated, it is necessary to sharpen the blade or simply replace it.

Fine-grained sandpaper is used to straighten the cutting edge of the blade. Sharpening with an abrasive stone is impractical, since the wrong choice of processing angle will inevitably lead to blunting of the cutters and the need for constant sharpening.

Rough

A roughing plane is used not only for processing the edge of a sheet, but also for leveling it. It is with its help that the edge is perfectly smooth, which allows you to adjust the plasterboard sheets to each other with even joints to simplify the finishing of the surface.

Unlike an edge plane, the working surface of the roughing tool is located on the sole and is not a blade, but a kind of grater with many holes with sharp edges.

Working with the tool involves the master running it over the surface to be treated, carefully removing excess gypsum filler and cardboard edges from it.

A roughing plane is indispensable when you need to get a perfectly straight straight edge (90 degrees), and an edge plane when you need to create an oblique edge.

Drywall Sanding Tools

Sanding float is a tool with clamps for a sanding mesh. The grater is used for dry sanding of puttied plasterboard sheets and the seams between them.

The variable handle grater is also equipped with clamps and a hinged handle. The grater is used in hard-to-reach places. The grater handle is extended, which allows you to increase the radius of surface treatment. This device allows you to go beyond the area with high dust formation when sanding gypsum boards.

Vibratory sanders not only speed up the processing of the surface of a plasterboard structure, but also collect dust in special dust bags.

Criteria for choosing a plane for plasterboard slabs

In order to make the right choice of a plane that is suitable for processing exactly your type of plasterboard sheets, you should pay attention to the following parameters of this construction tool:

- Length of the working surface (for grinding tools). Typically it ranges from 14 to 25 centimeters. The larger this parameter, the more surface you can process in a shorter time.

- Working blade width. It is 15–42 millimeters. The value of this indicator should be chosen depending on the thickness of your gypsum boards. Some tools allow you to adjust the width, which makes it easy to use them to process a wide variety of types of gypsum boards.

- Work surface material. The blade itself is made of both regular and tool steel. It is preferable to choose the second option, since such steel is stronger and more durable in use.

You also need to choose a tool that will fit comfortably in your hand. There are many models here, from which it is easy to choose the one that suits you.

An important criterion when purchasing a planer for gypsum boards is its cost. Using this parameter, you can also find models in almost any price category. For example, the price of an ordinary small Russian-made instrument starts at 250 rubles, and for professional models from well-known companies such as Knauf, the price will be 3,500 rubles or more.

Drywall knives

knives for plasterboard In the process of covering walls with sheets of plasterboard, you will invariably have to trim the material, which can be easily done using a regular stationery knife.

Also on sale you can find special knives for drywall, which are affordable and easy to use.

A drywall knife should be sharp enough to allow it to cut through a layer of cardboard without leaving burrs on the front surface of the material.

Note that this edge knife can only be used if you need to cut through drywall in a straight line. If you need to make curved cuts, you will need to use an electric planer and other similar tools for working with drywall.

On both sides of the sheet, use a regular pencil to mark the future location of the cut and use a sharp knife blade to cut through the cardboard, slightly cutting the inner gypsum layer. A similar cut is made on the reverse side of the sheet. When turning over drywall, you must act as carefully as possible, since the cut sheet may break under its own weight.

Having made cuts on both sides, carefully tap the sheet of material with a rubber hammer or just a fist. Then carefully fold the sheet over the cut site. With this fairly simple method of cutting drywall, you can get high-quality edges that do not require additional processing.

How to make your own drywall planer

A do-it-yourself plasterboard planer can be made from available tools and materials that you will probably find in your apartment when decorating a room with plasterboard sheets. For this you will need:

- Metal guide profile (it is best to choose the Knauf brand, since cheaper analogs are not suitable for the strength and quality of the metal).

- A small piece of wooden board or block.

- Metal scissors.

- Screwdriver.

- Self-tapping screws.

The process of making a plane for processing drywall step by step:

- The length of the profile is measured so that it is approximately twice the desired length of the working surface of the tool being manufactured.

- We cut the side edges of the profile in such a way that when folded in half it looks like a box. But we haven’t put it all together yet.

- We apply one of the profile halves with the front side (this is the part that will be working) to the wooden surface and use a screwdriver to make through holes in it. The more there are, the better - it should look like a grater.

- Now we fold the profile in half and secure its side edges with self-tapping screws on both sides.

- Using a hammer, lightly knock out the too sharp protruding pieces of the profile around the holes.

- For ease of use, so that the tool does not slip out of your hand, its side edges and top part can be wrapped with electrical tape or covered with any non-slip material.

Varieties

When working with gypsum boards, two types of planes are used: roughing and edging.

A roughing plane is a tool that is used to smooth out the edge of a sheet of drywall. Thanks to it, you can get a perfectly smooth edge, which simplifies the installation of plasterboard sheets and the process of finishing the coating.

The roughing plane is distinguished by its appearance: its working surface is located on the lower part of the tool and resembles a kind of grater, which has many pointed holes, and not blades, like the edge model.

Structure of a roughing plane:

- frame;

- base - grater;

- pens.

This type of tool is easy to use: hold the sheet and slowly remove all roughness and irregularities. It should be remembered that gypsum does not shrink like wood, but is carefully ground down.

An edge plane is used to level the edge of drywall, as well as chamfering, the bevel angle of which is usually 45 degrees. This is how an angular cut is made. The blades of this tool are in the shape of a trapezoid; they can be shifted, which allows you to achieve the required processing depth.

Structure of an edge plane:

- frame;

- blade fixing screw;

- steel blades located on the side of the tool.

An edge plane with a high-quality steel blade can also be used when working with soft wood.

In addition to factory tools, you can make a plane with your own hands. In this case you must have:

- metallic profile;

- small wooden beam;

- scissors for use on metal;

- screws and a screwdriver.

- The profile is measured. It must be 2 times the required length of the working part of the tool being manufactured.

- The profile is cut in the middle with scissors, then bent, but not folded.

- On one side, many through holes are made with a screwdriver, attaching the profile to a wooden beam. The more of them are made, the better the performance characteristics of a homemade roughing plane will be.

- Then the profile is folded in half along the cuts. Two parts of the profile are secured to the sides with self-tapping screws, and sharp corners, if any, are bent. All irregularities are smoothed out.

- For convenience, the profile can be wrapped with insulating tape.

Edge plane for drywall. Making perfect joints

Due to its versatility, ease of processing, relatively low cost and excellent characteristics, plasterboard is becoming increasingly popular in finishing work. In any room, residential or work, today this material is used to level walls, create niches, erect partitions or multi-level ceilings. It is clear that special tools have appeared for working with it, one of which is an edge plane for drywall.

Drywall crown

plasterboard crown

If it is necessary to make holes for sockets, use special plasterboard crowns, which can significantly simplify this work. With equal success, such a crown for drywall can be used with a drill or screwdriver.

Such crowns are made of durable metal alloys, and a sharp cutting edge allows you to make holes with perfectly straight edges. Subsequently, there is no need to process the edges or sand them.

drywall cutters

On sale you can find various options for cutters and crowns for drywall, which differ in their diameter.

A drywall cutter can be used not only for making sockets; with the help of such a crown you can make the holes you need when laying communication pipes, installing various suspended structures, and so on.

Arrangement of edge planes

The design of the plane is quite simple and, as a rule, is familiar to everyone who has encountered wood planes, since there is no fundamental difference in the design. The difference is that the edge plane for drywall is not intended for leveling the surface, but for creating a chamfer on the edge of the drywall sheet at a certain angle (in most cases, the angle is 45°). The design of the tool is modified accordingly to perform this task.

The body of the plane is made of metal or polymer materials. Plastic tools, as practice shows, perform quite well, but most professionals still prefer metal planes. The cutting tip itself (most often trapezoidal) is attached to the body using a special screw. This allows you not only to change the knife if necessary, but also to set a certain processing angle or change the position to work with sheets of different thicknesses. It is clear that not all instrument models can be adjusted. In addition, you can find planes with two knives.

If the blade is securely fastened, it is possible to remove edges from wooden or plastic parts. However, it should be remembered that inappropriate use of the plane does not benefit it. To hold the tool in your hands, one or two handles are placed on the body. When choosing an edge plane, the handles are often given special attention, since the comfort of the grip affects not only the feel of the worker, but also the quality of the resulting edge. It is advisable to hold the tool with your own hands to evaluate how convenient it will be to use.

Devices and tools for transporting gypsum boards

A sheet of drywall can easily be broken if carried carelessly, so there are special devices for this. To hold the sheet at the calculated height (for example, when creating a multi-level ceiling or arch), specialized tools are also useful.

The following tools and devices for carrying and lifting sheets of gypsum plasterboard and gypsum fiber board will be useful in the work of builders and during repair work:

- Carrying handle models for moving 2 or more sheets by one or two workers;

- Lifts equipped with special supports with material fixation;

- Lifts for installation of ceiling plasterboard sheets;

- Universal devices for lifting and/or carrying gypsum boards;

- Stationary and mobile tables and mobile carts for transporting and lifting gypsum boards to a height (up to 20 units);

- Devices for moving gypsum boards, cutting, drilling, etc.

Some devices can be made independently, for example, frames with spacers, with the help of which it is convenient to mount sheets on a single-level and complex-relief (multi-level) suspended ceiling frame. This homemade tool for working with drywall helps to fix the sheet in order to attach it with self-tapping screws to the SD and UD profiles while the glue or solution dries.

Carrying for gypsum boards

Carrying handles have been developed for builders that can be operated by even one person. To move gypsum boards with the help of two people, a set of 2 handles has been developed, with which they grip the gypsum board products at the required height, and safely transport the sheet, holding it in balance with their free hand.

Grips

For single movement of gypsum plasterboard sheets (gypsum plasterboard and other types of drywall), there is a plastic or metal carrier that secures the sheet. This device is convenient to use for home repairs that are carried out alone.

Trolley on three wheels

To move several sheets of gypsum board or gypsum fiber board around the construction site, a special modernon trolley with a load capacity of ≤ 400 kg is immediately used. Trolley length ≈ 1200 mm, width ≥ 5600 mm. When transporting gypsum boards, they are placed on their end with an inclination of 2-3˚. The wheels of such carts are made with different diameters - the large size makes it easier to move the slabs through an area cluttered with garbage.

Mounting support

This is a lever mounted on a special stand for sheets, equipped with a movable steel stop that holds the gypsum plaster boards. When attaching sheets to walls, niches or partitions, the lever holds the sheet vertically to make it easier to fasten. The bottom end of the plasterboard is not damaged.

Pedal lift

The device allows you to quickly attach gypsum boards with pressure to the surface. Requires the help of a second person.

Frame type lift

The device is used for fastening sheets at height, and helps when creating complex structures from plasterboard, parts of the ventilation system or artistic architectural elements. For example, a lift allows you to transport and place a sheet vertically or horizontally, securely fixing it before attaching it to the frame. The frame device has wheels for safer and more convenient movement of plates, weighs 20-30 kg, and can lift sheets weighing up to 50 kg by 3 meters. The device is designed for use by one person.

Spacer

Such equipment is easier and cheaper to make yourself. This is a T-shaped support structure made of timber or slats. The length of the support is determined by the height of the ceiling on which the gypsum board slabs will be attached. To lift and fix one sheet, you will need two of these spacers. Often used instead of an industrial lift.

Operating principle and application features

Using a drywall edge plane, cut the edge of the sheet at the required angle. After joining the sheets, a small groove remains at the joint, which is sealed with serpyanka, followed by filling the seam with putty and sanding. For high-quality processing of external corners, it is imperative to use a metal corner, since the sharp corners of the gypsum board are quite fragile and the corner will crumble without additional strengthening.

To move the tool, press on the rear handle. The front one is used to guide the plane. The front handle can also be used to adjust the thickness of the material being removed. The tools are equipped with a ruler and a side stop. The corner stop allows you to cut the edge at the required angle. When chamfering, do not press the tool too hard. Gentle pressure will result in a better-quality edge, while too much pressure will result in a damaged edge of the sheet.

The blade is sharpened with a special sharpener, which is usually supplied with the plane. However, you don’t always need to sharpen the knife - you can turn it over and use it further. As the cutting part wears out, it is simply replaced with a new one, especially since many companies use knives of the same shape and there are no difficulties in purchasing them. The price of a new blade is small.

How is a planer different from a jointer?

Externally similar planers and jointers differ significantly - more than other types. The first one is small in size, the second one is large and longer. Thanks to this, the jointer is suitable for large areas - the processing speed is higher.

Carpentry tools (planes)

Cutting part: the jointer has 2 blades (versus 1 for the plane). Taking into account the blades and length of the jointer, it removes unevenness better. The finishing signal is a continuous ribbon of chips rather than individual thick spirals.

The key difference is the use of a jointer to smooth out the edges before gluing. Extended straight lines are ideally processed for alignment.

Prices and models of edge planes

Due to the fact that this tool is quite simple, the price of an edge plane for drywall is usually not too high and averages 400–750 rubles. Sometimes craftsmen make planes, especially roughing ones, with their own hands. However, is it worth spending time making a tool that is available in any hardware store and is quite cheap? As usual, everyone decides for themselves. Let's look at several models of edge planes.

FIT 15025

The tool is a simple plastic edge plane, inexpensive and practical, designed to cut drywall edges at 45° or 22.5° angles. The position of the blade is adjustable for different sheet thicknesses (for 9.5 mm, 12.5 mm or over 15 mm). The cutting tip-blade is made of tool steel and works for a long time without replacement. The price of a plane starts from 300 rubles, which makes it accessible to virtually everyone.

Stayer Profi 18855

Made of steel, the Stayer Profi 18855 plasterboard edge plane is equipped with two angled blades. The position of the cutting edges is adjustable. The tool has two comfortable plastic handles that provide comfort and reliability in holding the plane. The cost of Stayer Profi 18855 is low; like its analogues, it is designed for cutting edges and forming chamfers on the edges of drywall sheets. Use on soft wood and plastic is not excluded.

Edge plane "Kantenhobel"

The purpose, like other tools, is to trim the edges of the Knauf sheet. The angle can be set to 22.5° or 45°. Despite the fact that the price is relatively high, this is compensated by the highest quality of the Knauf company, which is practically a world standard in the production of drywall and tools for working with it. "Kantenhobel" was initially aimed at professional drywallers, but can be used by amateurs and inexperienced workers - there is nothing complicated in its use. Simplicity and reliability, safety and convenience, as well as good value for money make this tool attractive to builders.

Varieties

There are several types of drywall. Each has its own characteristics, advantages and disadvantages. Let's look at them in more detail.

Material categories

It is divided into 4 categories:

1. GKL is one of the universal, simplest and cheapest types of drywall, which is used only in fairly dry rooms. Among the disadvantages is the lack of moisture and fire resistant characteristics.

2. GKLV - green sheets that are resistant to moisture, therefore they are widely used in toilets, bathrooms, and kitchens.

3. GKLO is a type of drywall that has high fire resistance.

4. GKLVO - sheets combine all the characteristics of the second and third varieties and have the highest resistance to moisture.

Let's take a closer look at the properties of all types of drywall.

Ceiling

It is used in the manufacture of all kinds of ceiling coverings - to create both single-level and multi-level boxes.

Laminated

This is a new generation finishing material made using the latest technologies developed by leading German specialists. This drywall is on a fabric base, it is characterized by easy installation, the absence of screws, wear resistance, and ease of maintenance. It is used not only as a practical material, but also as a bright decorative element, because it can imitate natural stone, wood, brick and all kinds of fabric.

Arched

Thin and light, so it bends well without cracking or being damaged. One of its main advantages is that before performing installation work, the surface does not need to be sprayed with water to impart better plasticity. Such drywall, thanks to its unique characteristics, allows you to create luxurious interior arches, columns, oval and rounded walls, and semi-arches. Its thickness is only 6.5 mm, so often several layers of sheets are used for greater strength and stability of the product.

Acoustic

It has soundproofing properties (the back side is equipped with spunbond) and is a perforated material. Its peculiarity is the presence of a large number of small holes with a diameter of 1 cm. Thanks to its unique properties that provide sound insulation, such plasterboard is used to cover shelves, walls, and floors in rooms where complete silence is required (for example, a recording studio, music school, etc.).

Fire resistant

GKLO (gypsum fiber sheet) is a non-flammable wear-resistant facing material. The core contains all kinds of special additives and fibers for reinforcement. They are used to decorate chimneys, fireplaces, shafts and other places with increased fire safety requirements.

Moisture resistant

Installed in rooms where there is a high level of humidity. This property is achieved through the use of moisture-resistant cardboard and core in the material. Antiseptic components are also added to it, which protect the surface from the formation of fungus and mold.

Fire and moisture resistant

This is one of the most wear-resistant options, which combines the characteristics of GKLO and GKLV. They are used to line production areas where fire safety comes first. Also suitable for those rooms where the humidity level is above normal.

Facade

Used for decoration, insulation of the house and protection from external negative factors. The properties of the material are ensured by its unique structure and composition - the outer layer is treated with hydrophobic agents. This impregnation prevents the penetration of moisture into the surface and makes it maximally protected from various external influences. Among the main advantages are fire safety, low price, ease of installation, and simple maintenance.

Reinforced

It is often used for laying on the floor due to its high strength (the cardboard layer is reinforced on both sides). It contains a reinforcing layer made of fiberglass; the back and front sides are treated with a water-repellent agent, which ensures its moisture resistance and long service life. The material is also sanded and impregnated with substances that protect it from chalking.

Drywall planer: 2 types of tools used by real pros

For some operations, a plane will be very useful, and for others it will be indispensable!

An edge or roughing plane for drywall is a tool that the authors of gypsum board installation instructions undeservedly ignore. And indeed, it seems that you can do without such a device, but if you know how to work with it correctly, then its benefits will be undoubted!

Not long ago I had to master the technology of self-installation of gypsum boards, and, having suffered with joining sheets, I took up the plane. I will share my experience in choosing such devices and working with them in this article.

Tool requirements for purchase and price

When choosing and purchasing a plane, it is worth noting some details:

- The blade should be easy to change. Blade material – steel. If you plan to work with a plane a lot and every day, then it is better to purchase a plane made of tool steel. The replacement blade must be commercially available.

- The grater, in a roughing plane, should be up to 3 cm. Larger sizes of drywall are suitable for work that is extremely rare; the thicker the gypsum board sheet, the wider the canvas should be.

- The optimal length of the grater blade is 25 cm; if the blade is long, it will be inconvenient to work with a plane; if it is short, the peeling process will take a lot of time.

- The edge plane should have a comfortable handle. If the plane does not fit comfortably in your hand, it will cause a lot of trouble during the work process.

- The tool is made of either plastic or metal. If you plan to work with a plane every day, then the metal body will last longer.

This option is possible: purchase a plane with a plastic handle, and then, independently, replace it with a wooden one. The price also shows the quality of the planes. Average:

- the price of a roughing plane is 350 rubles;

- the price of an edging tool is 450 rubles, a stayer 18855 plane costs 650 rubles.

Types of instruments

Type 1: roughing

The roughing model can also process wood - however, the blades will have to be changed more often!

It is difficult to deny that drywall, as a finishing material, has a lot of advantages. On the other hand, it also has disadvantages, and one of them is the fragility of the edge. After sawing the gypsum board, the end turns out to be quite uneven, so that under any impact, fragments of the gypsum filling break off: naturally, it is almost impossible to qualitatively join such parts.

To level the edge part after trimming, so-called roughing planes are used:

- The basis of the product is a steel frame on which the remaining parts are fixed. As a rule, the frame is mounted in a plastic or wooden case, which makes the shape of the plane more ergonomic;

Standard plastic model

There are models with a completely plastic frame, but they break quite quickly (or maybe I was just unlucky). So you can purchase them only when you need to correct no more than a dozen sheets.

- A cloth is attached to the bottom of the frame for stripping the edges of the gypsum board. The design of the canvas is, in fact, the kitchen grater we all know, consisting of many holes with sharp protruding edges. By the way, roughing planes are often called graters;

Putty tools

Tools for preparing the solution and applying it to the surface of the plasterboard must be made of stainless steel. The quality of a plastered or puttied surface depends on proper mixing of the solution. The mixture is mixed with attachments (construction mixers) inserted into a drill, hammer drill or screwdriver.

Nozzles for preparing the solution

- Use a mixer with a round paddle to mix paintwork materials, sealants and adhesive mixtures;

- The spiral nozzle with a ring at the end is designed for working with plaster mortars, fillers and leveling mortars;

- A left-handed three-turn spiral nozzle is needed for mixing liquid compositions with a low viscosity coefficient;

- A right-hand spiral nozzle is needed for preparing heavy solutions with a high density coefficient;

- The screw ring nozzle is designed for primers, paints and varnishes, adhesive mixtures and spray solutions.

Spatula

- Using a spatula with a 50-70 cm blade, seal the seams between the plasterboard slabs, press the reinforcing tape into the solution to fasten the seams between the gypsum boards, apply putty along the long side of the seam and on the entire sheet;

- Using a narrow corner spatula, level the outer and inner corners of the gypsum plasterboard structures, and also seal the transverse seams;

- Using a spatula and a screwdriver, putty the gypsum board seams and the recesses from the screw heads;

- Using a wide spatula with a blade length of 180 cm, plasterboard slabs are completely puttied;

- A putty falcon is a stainless steel shield on which a solution is applied and brought to the place of putty.

Using a plane

How to straighten an edge

Well, if we’ve sorted out the choice, now I’ll talk about using planes when installing gypsum boards with your own hands. I'll start with a description of the work of the roughing model:

When sawing, the edge turns out to be uneven due to uneven fracture of the gypsum

- A plasterboard grater is used when we need to get the most even edge possible - for example, when a sheet is attached to any surface at an angle of 90. It is difficult to achieve such a result with just a neat cut: no matter how hard we try, the plaster will still crumble;

- To align the end, we lay the cut part so that it is as convenient as possible for us to work. As a rule, the edge is located at the top, but if we need to sand a small area, then it can be oriented vertically;

- We place the plane blade on the edge and run it along its entire length, removing excess material. Strong pressure is not needed here: it is better to perform three or four passes, peeling off a thin layer, than to cut off a lot at once, and therefore waste time correcting the curvature of the end;

- Every two or three movements, remove the plane from the drywall and clear the plaster from the float. To do this, just turn the instrument on its side and tap the body with your palm.

Using a small rasp it is convenient to adjust the edge profile exactly to the shape of the adjacent surface

After completing the work, we control how well we cleaned the edge using a level or rule. You can also apply drywall to the surface with which we will be joining it: the smaller the gap, the better.

How to join sheets with chamfering

Instructions for using an edge plane will differ:

- We lay the sheet of drywall on a flat surface or install it so that the edge we need is located on top;

- We check whether the plane blade is positioned correctly: it must be securely fixed at the angle we need (as I said above, most often it is 450);

- Place the plane on the edge on the desired side and run it along the sheet. In this case, the blade should remove the chamfer, exposing the gypsum layer.

Photo of grooves formed at the junction of two sheets of drywall

This technique makes it possible to ensure the most durable connection between the joint of two sheets: both when gluing with serpyanka and when putting putty, the contact area with the material increases due to chamfering. In addition, the exposed gypsum layer has much better adhesion to putty mixtures (compared to cardboard), so this will provide us with an additional advantage.

It is worth noting that only the smooth ends of gypsum boards and the edges of sheets after trimming are processed with an edge plane. Edges with factory rounding can be joined without chamfering - just sand the cardboard for better adhesion.

Rounded edges do not require planing

If, using a plane, you do not chamfer, but cut the entire edge of the sheet at an angle of 450, then you can perfectly straighten the corner of the room. True, in this case the joint must be covered with a protective corner and carefully leveled using putty, since the thin edges on the edges are guaranteed to crumble under any impact.

At the junction of two chamfered sheets, the putty holds much more firmly

Tools required for cutting and processing gypsum boards

There are a number of tools and devices that are used for cutting and processing plasterboard sheets.

Cutting table

This device consists of two support legs with thrust elements attached to them. There is a lattice cover on top, on one side of which a pressure ruler of the appropriate length is fixed using special clamps.

Folding workbench

An equally convenient device, the main difference of which is the removable cover, which allows, if necessary, to fold the support frame for subsequent transportation. For this purpose, special loops are designed, which are located on the end crossbars.

The material is cut using a construction knife or a cutting tool designed directly for drywall.

Sheet cutting knives

To cut the top cardboard layer of gypsum boards, special knives are used.

Narrow cutter

The device is necessary so that it is possible to cut a strip from a full-size sheet, the width of which does not exceed 120 mm. This cutting is carried out by two discs that simultaneously cut the material on both sides. Some models of such devices are equipped with an additional handle, which makes them more convenient to use.

Wide cutter

Works on the same principle, but is used to cut larger pieces of drywall. The permissible limit for sheet width in this case is 630 mm. At the same time, cutting with a regular knife gives almost the same results, which explains the rather low demand for such devices.

Hand saw

To create rectangular holes or elements with complex shapes, you will need a hacksaw with a minimum blade width and fine teeth. Such tools are made specifically for working with gypsum boards.

Roughing plane

The tool is a type of rasp with which the edges of cut sheets are processed, which allows you to align them and achieve ideal smoothness. The tool involves the use of replaceable blades, the installation of which is carried out by loosening and tightening the tension screw.

Edge plane

An edge cutter is used to trim the edges of edges to create chamfers. In this case, the angle of inclination can be 22.5 or 45 degrees. Before using the edger, the ends of the sheet must be leveled using a roughing plane.

Circular cutter

A special attachment for a drill allows you to make standard holes in drywall necessary for installing all kinds of communication elements. Such products are mainly sold in sets and have different diameters, which makes it possible to choose a cutter for a specific purpose.

Ballerina for gypsum boards

This tool also creates holes. In this case, their variable diameter is assumed, which can vary in the range of 12-320 mm. The device consists of an aluminum body and a particularly durable cutting element in the form of a roller made of carbide materials.

Needle roller

This device is used exclusively in cases where it is necessary to give the material an arched shape or create another type of curved surface. Water is applied to the plasterboard sheet, which, during the perforation process, penetrates directly into the body of the gypsum layer. The depth of the holes is 5-7 mm, and their diameter ranges from 2-3 mm. In this case, the side on which the recesses are made should be concave.

Metal scissors

The tool will be needed during the profile cutting process. This is an excellent alternative to a hacksaw, which is not always convenient to work with in certain conditions.

Power tools

These primarily include an angle grinder and a jigsaw, which can, in some cases, significantly simplify the work. Small electric scissors will also come in handy, allowing you to reach hard-to-reach places.