Snow removal in a small area does not require powerful equipment.

By small area we mean:

- parking area in front of the garage;

- path from the house to the gate or garage;

- local area;

- sidewalk near the house.

This kind of cleaning is easy to do with either a conventional or mechanical shovel . But such devices are only suitable for shallow snow due to the small size of the bucket.

To remove a thick layer of snow over a rather large area, a shovel is not enough - you will need more serious equipment .

For such work, it is important to purchase gasoline snow blowers . They are used for cleaning large areas , such as:

- playground;

- road in front of the house;

- parking near the store;

- school stadium.

Types of Gasoline Snow Blowers

All gasoline snow blowers are distinguished by the type of chassis and ease of use . There are two types:

- self-propelled;

- non-self-propelled (manual).

For a comparison of the operation of gasoline self-propelled and non-self-propelled snow blowers, see the video:

In addition, snow blowers are divided by the number of stages of the snow removal system:

- single-stage (auger);

- two-stage (screw and rotor).

Gasoline snow removal units are also divided into:

- engine type;

- motor power;

- the presence of a headlight;

- width and height of the bucket;

- weight;

- cost.

Step-by-step instruction

Snow blower “shovel”

- We make the frame. To do this, it is ideal to take a metal corner or a profile pipe, which must be made in accordance with the technical features of the unit. At this stage, do not forget about the metal corners that will play the role of support for the diesel engine.

- At the end of the first stage, we attach the handles that will be used for control, choosing for this purpose those that will be the most rational and convenient to grip.

- Motor. It can be taken from a small-sized tractor or from a grass-cutting machine, and then firmly attached to the frame.

- To avoid many problems in the future, it is necessary to manually start the engine, because installing a generator and battery significantly increases the weight of the snow removal unit.

- Rotating auger and intake bucket. The system that will collect snow must be made from steel elements, having previously cut them into the necessary parts, taking into account the height and length.

- The rotating auger can be replaced with a conveyor belt, and in order for the snow to be thrown to the required distance, it is best to weld a steel pipe of the selected diameter and the required length.

- The bucket, or rather its lower part, must be “decorated” with plastic material, which will easily move through the snow. Guide elements can be made from simple bars.

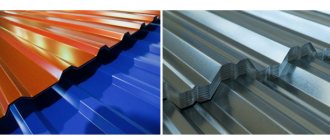

- The bucket, as an option, can be constructed from roofing-type iron, and its side elements can be made of plywood. The width of this part cannot be less than fifty centimeters. The diameter of the pipe through which snow will be thrown should not be less than 16 cm, otherwise large pieces may simply clog the pipe.

Snow Blower Bucket

If you also install plastic pads, the structure will ride more easily and smoothly in the snow. But there are also owners who prefer to put the car on wheels, well, it’s up to you, some even manage to use skis instead of wheels.

The wheel frame is the basis of the snow removal structure. The following will be attached to it:

- Control handle.

- Motor.

- Fuel tank.

- A bucket that catches snow with support guides.

- A pipe that performs the function of throwing out snow.

- Work equipment.

Therefore, you should consider that your machine should be based on a platform that is strong and lightweight at the same time. Do not forget that it is you who will perform the function of the main traction force. If you can’t do this, then you can always buy a Patriot self-propelled gasoline snow blower, which is much easier to operate.

Snow blower platform

Optional equipment

Not all units are equipped with additional equipment , which is why it is called additional. Such equipment easier to use .

The most common headlight , which sometimes comes standard with even very budget models.

The headlight bulb operates from a generator connected to the engine and provides an ignition spark, so the headlight does not light up when the engine is turned off.

The headlight makes snow removal in the evening and at night , as well as in poor visibility .

About half of the models are equipped with a two-stage snow removal system , which consists of 2 parts:

- auger

- and rotor.

In order for the auger to give the snow the necessary acceleration, its rotation speed has to be greatly increased. This negatively affects the service life of the auger and is especially dangerous if there is a possibility of the auger colliding with a hard surface, including ice.

The second stage allows you to reduce the rotation speed of the auger by 2–4 times , and also use a screw-shaped auger, which has better performance. After all, the task of the auger is to feed snow to the rotor, and the rotor will give the necessary acceleration to the snow being removed.

The snow blower auger with a two-stage snow removal (cleaning) system is not afraid of contact not only with ice , but even with asphalt or concrete .

The third type of additional equipment, which is installed only on snow blowers with electric start, is an electric starter . It is performed in two versions - with power from:

- battery;

- AC mains.

A battery electric starter is noticeably more expensive , but it allows you to comfortably start the snow blower even far from an outlet or in conditions where there is no electricity , and therefore is more versatile .

Snow blower from a cultivator - for power lovers

This option has such advantages as fairly high power, cross-country ability and snow throw range. At the same time, such a unit consumes a large amount of fuel and makes a lot of noise during operation.

It is important to remember that the cultivator is not designed to work in severe frost conditions. In this regard, the engine of a homemade snow blower needs to be regularly warmed up before you start clearing snow.

In order to protect the motor, the machine body will need to be equipped with protective metal plates.

A snow blower made from a cultivator can be used in large areas, up to 15 acres. When operating, use high-quality seasonal motor oil. At the end of the winter period, the bucket and auger mechanism can be dismantled and the cultivator can be assembled for tillage.

Basic and additional parameters of snow blowers

When choosing snow blowers, you have to take into account their various parameters and characteristics . Indeed, despite the fact that the general task for these devices is the same - snow removal - the requirements of each buyer are individual.

Main settings

All gasoline snow blowers are divided according to several basic parameters .

Horsepower (hp):

- low-power ( up to 4 hp );

- medium power ( up to 7 hp );

- high power ( over 7 hp );

Weight in kilograms (kg):

- light ( up to 40 kg );

- medium ( up to 90 kg );

- heavy ( over 90 kg );

Cost in rubles:

- inexpensive ( up to 30 thousand rubles );

- medium ( up to 60 thousand rubles );

- expensive ( over 90 thousand rubles ).

Weight is a very important parameter when choosing a snow blower, especially when it comes to non-self-propelled gasoline models. After all, it is difficult to roll a heavy snow blower into a barn or hangar on your own, which means that a teenager or woman will not be able to work with it.

Everyone’s financial capabilities are also different, so when choosing, you will have to pay attention to devices from the appropriate price range.

Unfortunately, the most inexpensive snow blowers are not distinguished by high engine power and the presence of self-propelled propulsion .

Extra options

Additional parameters that may affect the choice of a snow blower and the ease of use include:

- throwing distance, snow in meters;

- performance (this parameter depends on many factors);

- noise level ;

- fuel consumption, liters per hour.

When choosing a gasoline snow blower, focus not only on the basic , but also on additional parameters. Everyone's needs are different, and sometimes specific requirements are best met by an inexpensive snow blower. And it happens that a model with the required characteristics is in a different price range.

Snow throw distance describes how far the unit will throw snow. This distance varies from 4 to 12–15 meters and depends not only on the power, but also on the presence of a second stage rotor. In addition, the snow condition also affects the reclining range.

Screw option

A device with a blade has drawbacks, and the main one is the waste of time and effort to remove the layer of snow picked up by the blade. Often it is left right next to the road, creating high snowdrifts, which is not always acceptable.

The version of the snow blower with an auger will allow you to get rid of even roadside sediment, because its design provides for the throwing of the captured mass over a distance of several meters. This will help clear the yard or street completely, leaving the piles next to the fence.

This option is welded or screwed from the front to a frame with wheels, which can be removed from an old wheelbarrow, for example.

Another design is a wheelless version, controlled by a tube. The body is mounted on a frame made of angles, from the bottom of which skis are screwed.

Main components and materials of both options:

- box - welded from sheets of metal;

- central shaft - is a ¾-2 inch pipe;

- gripper (scapula) - iron plates or pieces of channel;

- supporting elements;

- auger - made of rings or tape;

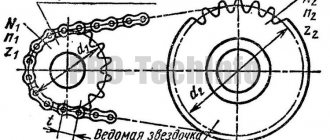

- motorcycle sprocket;

- ski made of plates or pipes;

- frame made of corners;

- bearings;

- a pipe for throwing out snow - you can take it from the stove.

Screw assembly sequence:

- 4 rings and 6 support plates are cut from roofing sheets or other metal.

- Six strips are placed on the shaft and welded to it at an angle of 90°. Then the sprocket is strengthened and the bearings are pressed in.

- Two blades made of plates are inserted between the middle guides. They are welded to the shaft and to the supporting elements. If pieces of channel bars are used as gripper blades, they are rotated 180° relative to each other.

- The rings are cut, bent and welded so that two intersecting spirals are obtained.

You can straighten them in two ways:

- Clamp the middle part in a vice, grab one edge with pliers and pull it to the side. Do the same with the other end.

- Weld one edge to the support element at the blade and stretch it.

If the rings are made of thick material and it is difficult to grasp them with pliers, then you can use two clamping devices, such as a vice.

After making the auger, a sheet of metal is laid out and the box is welded. A hole is cut out in its middle part for a pipe to throw out snow. You can make it yourself or use one already prepared from an iron stove. Some craftsmen use plastic ones.

Then a rectangular hole is cut in the body opposite the sprocket to allow the chain to pass through. The box is installed on a frame with runners or wheels and the chainsaw is strengthened.

Best models

We have compiled our own rating , which includes the best (in our opinion) snow blowers of each type .

In addition to listing the models, we will indicate their advantages over other similar units, as well as disadvantages (if any).

When compiling the rating, we used both the technical characteristics of snow blowers indicated on the manufacturer’s official website, as well as reviews from owners of such devices published on various forums.

Non-self-propelled

AL-KO SnowLine 55E is a very expensive device for its price category, the main advantages of which are:

- presence of an electric starter,

- powerful motor.

Thanks to its power, which is somewhat excessive for non-self-propelled units, it easily copes not only with fresh, but also with compacted snow. However, this is not a self-propelled machine, so it is less convenient to operate than most self-propelled snow blowers. On Yandex Market the price of the device is on average 35 thousand rubles .

CHAMPION ST655BS – this device takes second place. It is also equipped with an electric starter, but the motor is inferior to the leader in power, in addition, many users note the low reliability of the auger . On Yandex Market the cost of a snow blower is 33 thousand rubles.

Self-propelled wheeled

Interskol SMB-550 is one of the cheapest, but reliable and productive snow removal machines.

The engine power is enough to clean the area around the house, and the toothed steel auger easily crumbles even compacted and dense snow. The auger-rotor mechanism throws snow 5–12 meters , and the deep wheel tread (lugs) provides reliable grip on the road surface.

The cost of such a snow blower, according to Yandex Market, is 36 thousand rubles.

CHAMPION ST1170BS is the most powerful wheeled snow blower in the Champion line, and is also equipped with an electric starter. At the same time, the device is relatively inexpensive , about 69 thousand rubles, because most units of this power are much more expensive.

The snow blower easily copes with deep, compacted and wet snow, throwing it 10 meters or more. With good care it is very reliable. You will find more detailed information on the manufacturer's website at this link.

HUSQVARNA ST 230P is a very expensive , convenient and not very powerful snow blower, equipped with an electric starter. Its advantage is the ability to lock one of the wheels for better turning.

In terms of technical characteristics and real capabilities, it is seriously inferior to the previous snow blower, but many are willing to pay about 140 thousand rubles for a wheel drive with a differential and a well-known brand. More detailed information about this snow thrower model can be found at this link.

Self-propelled tracked

PATRIOT PRO 1150 ED is an inexpensive and at the same time quite powerful and reliable unit, equipped with functions inherent in snow throwers of a more expensive segment, that is:

- electric start,

- heated handles.

Power 11 liters. With. enough to clear even densely packed snow, and the bright headlight allows you to work at night. The cost of this device is 86 thousand rubles, and a more detailed description is available on the manufacturer’s website.

AL-KO SnowLine 760TE - this snow blower takes second place due to its standard equipment for its price, a slightly more powerful motor and the manufacturer’s reputation . However, it does not have any serious advantages over the leader, and it costs noticeably more. On the manufacturer's official website you can find its detailed characteristics. According to Yandex Market, its price is 129 thousand rubles .

HUSQVARNA ST 327PT - the snow blower occupies third place in the rating due to its price. Its cost is 210 thousand rubles , despite the fact that the only advantage is a hydrostatic transmission.

An engine of this type is more reliable due to friction, however, in the event of a breakdown, the cost of repairs will be 3–5 times higher. In terms of its capabilities, it is comparable to the leaders of the rating. More detailed characteristics of this snow thrower can be found on the manufacturer’s website at:

Do you still have doubts about whether to buy a gasoline snow blower? Watch the video:

Mechanical diagram

The design of a snow blower is quite simple and is based on a supporting frame. An engine, a snow bucket, and handles are mounted on it.

The main working part is the auger, which, while rotating, collects and moves snow to the impeller, where the snow mass is captured by the blades and fed first into the cavity of the mechanism, and then into the exhaust pipe.

The diagram of a homemade snow blower clearly demonstrates the structure of the unit.

Scheme -1

The simplest snow blower is a single-stage one. The capture and discarding of snow from snow blowers Champion 656, lux 163, Patriot is carried out only by a rotating auger. In two-stage designs, the auger is complemented by a metal blade plate (rotor) attached in the middle of the drive shaft.

Video: Homemade rotary snow cleaner

For more information about the rotary snow blower, watch the video:

This design is used for removing large volumes of snow and ensures its throw at a distance of up to 12 m.

Engine power determines the type of snow blower:

- Manual, mechanical. Engine with a power of 2.5-5 hp. activates the working parts, and the movement of the unit is due to the physical force applied by the user. A mechanical snow blower is the easiest to make with your own hands.

- It is curious that a “mechanical snow blower” is also called a plastic shovel with a handle in the form of a metal bracket, equipped with reinforcing ribs on the back side, with a rotating auger attached to the front side.

- If you keep the shovel at the correct angle so that the auger does not hang in the air, but rather rotates, this version of a “motor shovel” without an engine is very effective for cleaning uncompacted snow (up to 10 cm) in small areas, especially in hard-to-reach places.

- Self-propelled. A fairly powerful engine, from 10 hp, ensures the operation of the equipment and the movement of wheels or tracks.

Tracked snow blower

Mini tracked vehicles

When loaded in deep snow, a crawler drive is preferable. It’s easy to make a snow blower with your own hands on caterpillar tracks from a tracked radio-controlled children’s car. A mini tractor with caterpillar tracks is also suitable.

This design can be equipped with headlights, a webcam and controlled remotely (remote control). Mini snow removal equipment on caterpillar tracks is considered the most productive.

Where is this technique used?

A universal snow blower is designed to clear large areas of snow. The basic principle of throwing the snow cover to the side is similar to human labor, only more economical. There are no complex components in their design, which increases operability and maintainability.

Roads and road transport structures of any complexity. Special design workshop “Spetsroad”: TDR – traffic management project. Design since 2010, significant experience in passing and approving state and commercial examinations.

In addition, anyone can handle their operation. With a large area, it is simply impossible to do without such a device.

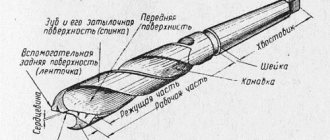

Do-it-yourself snow blower: making an auger and frame

The snow blower consists of a welded metal body, inside of which there is an auger ─ this is the main working element. It is a spiral-shaped profile welded onto a shaft that rotates on bearings. It is necessary to secure the engine to the frame and transmit the rotation of the engine shaft to the auger. A small gap between the auger and the box provides excellent removal of collected snow.

Making a screw with your own hands

In order to make an auger, we need an old box or sheets of iron that need to be bent to the shape of the auger.

Diagram of a screw mechanism for a snow blower

Manufacturing consists of the following stages:

- cut out 4 disks from sheet steel;

- cut the disks in half, bend each disk into a spiral;

- We weld four blanks into a spiral on the pipe, on one side and four on the other;

- We put bearings on the edges of the pipe.

You can use any bearings, as long as their internal diameter matches the diameter of the pipe. Glasses for installing bearings are welded into the sides of the snow bucket.

DIY snow blower frame

The frame for a homemade snow blower is obtained by welding 50 mm corners, to the crossbars of which strips for a quick-release engine platform are mounted. It is necessary to attach skids or wheels to the frame to move the snow blower. If the surface to be cleaned is perfectly flat, then wheels are sufficient. For uneven surfaces and deep snow, runners are appropriate.

Do-it-yourself auger snow blower assembly diagram

Read also: Staples for staplers, types, sizes, stationery

The controls are attached to the frame with M8 bolts. Next, an easily removable platform is screwed onto which the engine is installed.

DIY snow blower video

Do-it-yourself snow blower: useful tips

In order for the snow blower to work for a long time and be a reliable assistant for a long time, it is recommended to follow the advice of professionals:

- In order to prevent stones or ice fragments from entering the engine, it is worth adding safety bolts or bushings to the design. Without them, there is a risk of the engine jamming.

- The choice of bearings plays an important role in the reliability and durability of the unit. They must be closed, otherwise snow may get inside, which will lead to accelerated wear and tear.

- It is better to take a belt drive than a rigid one. Since there is a possibility of jamming of constantly moving parts when large objects or ice hit. The motor may seize, causing the snow blower to break down. In such a situation, the belt will simply slip.

DIY snow blower

By following the instructions and advice of experts and having technical skills, you can assemble the unit, and thereby save on the purchase of equipment. And if the snow blower you assembled with your own hands is also painted, then it will be no different from the one you bought, and its service life and quality of work will be no worse.

You can assemble a snow blower with your own hands with an electric motor and a gasoline engine. In order for the homemade product to meet its purpose, you need to know the basic structure of special equipment for snow removal. Moreover, a snow blower can be an independent unit with a motor or a hitch that requires connection to a drive, for example, a walk-behind tractor.

How to make a rotary snow blower with your own hands

You can make a powerful do-it-yourself rotary snow blower for your home using a gasoline engine. Additionally, you will need a fuel tank, a muffler, and a cable for connecting the throttle control to the handle of a homemade unit. The rotor shaft can only be manufactured on a machine. The snail, frame and other elements are independently welded from metal.

Description and preparation of components

The technology for assembling a homemade rotary machine is similar to creating a snow blower from an electric scythe. In a similar way, a snail is made from a beer barrel. If in the trimmer the gearbox was bolted to the bottom, then here the rotor is made homemade. The design consists of two bearings on a shaft. They are mounted in hubs, which are attached to the rear wall of the cochlea. An impeller with blades is mounted on the shaft on the working side. The protruding part of the shaft beyond the volute is equipped with a pulley.

A homemade snow receiver is attached to the frame. The gasoline engine is mounted on adjustable skids. A belt connects the rotor and engine pulleys. To move around, the homemade car is placed on rubber wheels.

Advantages of combined units

A combined homemade snow blower consists of a screw and rotor mechanism connected together. The traction device is an electric or gasoline engine. The advantage of a homemade combined model is performance. The auger captures a wide strip of snow, grinding even compacted and slightly icy layers. The fine mass enters the volute, where the rotating impeller blades create a vortex. Crushed snow under high air pressure flies out of the discharge sleeve at a distance of up to 15 m.