What is a specification

Specification is a text document of several A4 pages that gives an idea of the structure of the product shown in the drawing. Having opened the special one and familiarized ourselves with the composition of the assembly unit, we do not need to study the entire drawing. And sometimes it can be rather big.

The special makes it easier to read the drawing, because it contains all the necessary explanatory information.

Specification and assembly drawing are working design documents.

If the explanatory document does not fit on an A4 sheet, then it can be continued on the next sheet, but the shape will be slightly different from the first sheet. The picture below shows how.

If possible, the specification can be placed next to the image of the assembly. The main thing is that the number of parts allows this to be done.

9.3. Applying dimensions

Dimensioning is the most critical part of working on a drawing, since incorrectly placed and extra dimensions lead to defects, and lack of dimensions causes production delays. Below are some recommendations for applying dimensions when making drawings of parts. The dimensions of the part are measured using a meter on the general view drawing of the assembly unit, taking into account the scale of the drawing (with an accuracy of 0.5 mm). When measuring the largest thread diameter, it is necessary to round it to the nearest standard, taken from the reference book. For example, if the diameter of a metric thread is measured to be d = 5.5 mm, then it is necessary to accept an M6 thread (GOST 8878-75).

9.3.1. Size classification

All dimensions are divided into two groups: main (conjugate) and free. The main dimensions are included in the dimensional chains and determine the relative position of the part in the assembly; they must ensure:

- location of the part in the assembly;

- precision of interaction of assembled parts;

- assembly and disassembly of the product;

- interchangeability of parts.

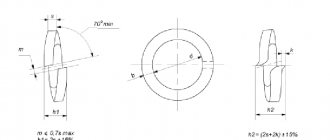

An example is the dimensions of the female and male elements of mating parts (Figure 9.2). The common contacting surfaces of the two parts have the same nominal size. Free dimensions are not included in the dimensional chains of the part. These dimensions determine those surfaces of the part that do not connect with the surfaces of other parts, and therefore they are made with less accuracy (Figure 9.2). A - covering surface; B – male surface; B – free surface; d – nominal size Figure 9.2

9.3.2. Dimensioning methods

The following sizing methods are used:

- chain;

- coordinate;

- combined.

With the chain method (Figure 9.3), the dimensions are placed sequentially one after another. With this sizing, each roller step is processed independently, and the technological base has its own position. At the same time, the accuracy of the size of each element of the part is not affected by errors in the execution of previous dimensions. However, the total size error consists of the sum of the errors of all sizes. Drawing dimensions in the form of a closed chain is not permitted, except in cases where one of the dimensions of the chain is indicated as a reference. Reference dimensions in the drawing are marked with a * and written in the field: “* Dimensions for reference” (Figure 9.4). Figure 9.3 Figure 9.4 With the coordinate method, dimensions are set from the selected bases (Figure 9.5). With this method, there is no summation of sizes and errors in the location of any element relative to one base, which is its advantage. Figure 9.5

The combined sizing method is a combination of chain and coordinate methods (Figure 9.6). It is used when high precision is required in the manufacture of individual elements of a part.

Figure 9.6

According to their purpose, dimensions are divided into overall, connecting, installation and structural.

Overall dimensions determine the maximum external (or internal) outlines of the product. They are not always applied, but are often listed for reference, especially for large cast parts. The overall dimensions are not applied to bolts and studs.

Connecting and installation dimensions determine the dimensions of the elements by which this product is installed at the installation site or connected to another. These dimensions include: the height of the center of the bearing from the plane of the base; distance between hole centers; diameter of the circle of centers (Figure 9.7).

A group of dimensions that determine the geometry of individual elements of a part intended to perform a particular function, and a group of dimensions for elements of a part, such as chamfers, grooves (the presence of which is caused by processing or assembly technology), are performed with varying accuracy, therefore their dimensions are not included in one dimensional chain (Figure 9.8, a, b).

Figure 9.7

| Wrong | Right |

Figure 9.8, a

| Wrong | Right |

Figure 9.8, b

Sequence of recording information

When designing specials, it is important to maintain a certain sequence and hierarchy. It looks like this:

- documentation . A set of documents containing various visual and textual information. Diagram, passport, assembly drawing, etc.;

- complexes - a certain number of documents that allow us to talk about one whole;

- assembly units . They are part of the overall assembly and include individual elements. They do something with these elements: weld, glue, rivet, etc.;

- parts are an object created from a single material and not consisting of any components;

- standard products - the application of which was guided by standards: from private enterprise standards to state ones;

- Other products . The main factor in their use is technical specifications, not standards;

- materials - everything that an object is made of. There is also a hierarchy within materials. For example, ferrous metals are listed first.

- kits . The set includes a minimum of 2 units of the object. This is a group of documents that perform an auxiliary function, are part of the product and come complete with it.

The composition of the product determines which of these sections will be specified and which will not.

The name of the section is indicated in the “Name” column.

How many specifications can there be for one contract?

The number of specifications for one supply contract is not limited in any way.

A separate document can be drawn up for each batch of goods. Each time after it is signed by the parties, it becomes another integral part of the main agreement.

What to pay attention to when preparing a specification

The specification can be drawn up on the organization’s letterhead or on a simple blank sheet of paper of any convenient format, either in handwritten form or by printing it on a computer.

Only one condition must be strictly observed: the form must contain the signature of the head of the supplier company or his responsible representative, as well as the signature of an employee of the organization - the consumer.

At the same time, their autographs should only be “live” - the use of facsimile signatures, i.e. printed by any method is not permitted, except in situations where the contract is concluded remotely, and enterprises have officially registered electronic digital signatures.

There is currently no strict need to certify the specification using stamps - it needs to be stamped only if the use of stamped products is prescribed in the regulatory legal acts of organizations.

The specification is drawn up in two copies identical in text and equivalent in law - one for each interested party. After formation and endorsement, information about the document is entered into a special log of contracts.

Can I make changes?

The same rules and requirements that are established for contracts (since they are part of them) are applied to the specification by law.

This means that, if necessary, at any stage, the finished specification can be edited by mutual agreement of the parties. It is also allowed to terminate previously drawn up and endorsed specifications and create new ones.

How, where and for how long to store a document

The specification for the entire period of relevance should be in a separate folder, along with the contract, to which it is an integral annex. The document storage period is determined either by the legislation of the Russian Federation or by local regulations of the company.

How to fill out

The rules for drafting are not defined in law. If it is drawn up for a supply contract, the following points are highlighted:

- Serial number.

- Name of the product, work or service.

- Specifications.

- Quantity.

- Unit of measurement.

- Unit price.

- Total cost for each item.

- Total amount.

The specification form for the service contract has a similar appearance, only the quantity is replaced by volume. Additionally, an execution schedule is prescribed.

IMPORTANT!

Such documents must be signed by all parties to the transaction and drawn up in the same number of copies as the contract.

Drawing up specifications in Excel and design in AutoCAD

With the introduction of the Table element in AutoCAD and the ability to link it to Excel tables, this method is the best of the list. Firstly, filling out a specification table in Excel, in addition to convenience, provides additional advantages (the ability to summarize or obtain information via links from other sheets or files). Secondly, data from Excel is automatically updated in AutoCAD. Thirdly, the AutoCAD table has the ability to automatically “split” into several fragments, which makes it possible to quickly and easily design specifications in separate sheets (both using the table in Model space method, sheets in Sheet space, and using the table and design in space method Models). The interval between fragments, as well as the height of fragments, are set in the table properties. Fourthly, when designing a specification in Sheet space, the specification can be included in a sheet binder, which provides additional advantages.

At the moment I am doing the specification in Excel and designing it in AutoCAD. Previously I used Excel+Word. I inserted it into Word in such a way that the data from Excel was updated. And to align on the page and adjust the width of columns in Word, I wrote a small macro so as not to do it manually.

Click on the button to download specification templates according to GOST 21.110-2013:

Subscribe and receive notifications of new articles by e-mail

Drawing up specifications in Excel and design in Word

This method combines the convenience of filling out specifications in Excel and the convenience of formatting in Word. The specification is filled out in Excel and inserted into Word, in which the frame and main inscription (stamp) are made in the footers. Next, the width of the columns is adjusted and the cable magazine is ready for printing.

It would seem that the disadvantage of this method is the need to first delete the old table each time, and then insert and configure a new one. But it is not so. Word allows you to link a Word table and an Excel table. Thus, when you update data in Excel, the table in Word will also be updated.

How to draw up a specification, sample

Today there is no unified specification form, so employees of organizations and enterprises can draw it up in any form or, if the company has a developed and approved document template, based on its sample. The main thing is to meet only two basic conditions: in its structure it must meet certain standards of office work, and in content it must include a number of certain data.

to header :

- number and date of conclusion of the agreement to which it is annexed;

- specification number, as annex;

- indicate the title of the document.

The second part of the form is the main one. It almost always looks like a table, which includes the following information:

- name of goods or materials;

- their unit of measurement;

- quantity;

- price for one;

- total cost.

If necessary, the table can be supplemented with other additional data.

Then, under the table, it would be a good idea to enter the terms of payment for products according to this specification (they may correspond to the terms of the contract, or they may be changed, depending on the circumstances).

What should the job be like?

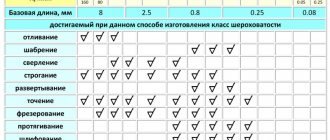

All rules according to which work must be performed and executed are regulated by GOST.

Work includes:

- a picture of an assembly unit, which shows how the component elements are located and connected to each other, as well as a picture showing its assembly and control;

- dimensions, maximum deviations, various characteristics and instructions that need to be followed or their implementation monitored;

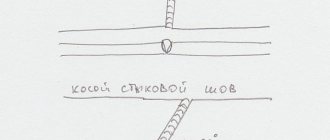

- information describing the pairing. Methods for its implementation can also be presented, when the precision of mating is carried out during assembly: fitting, selection of spare parts, etc. Information on the implementation of permanent welded, soldered and other connections;

- position numbers of the component elements of the product;

- information about the dimensions of the product. These include installation, connecting and other dimensions.

Drawing up specifications in Excel or Word and printing on forms

This is the most ancient method, which appeared during the transition from manual drawing to computers. The specification was compiled in Excel, because For a person who used to draw everything by hand, Excel is just a ready-made spreadsheet. In AutoCAD, using lines and text, we drew the frame and the title block (the first sheet and subsequent ones). After this, the forms were printed: one first sheet and the required number of subsequent ones. These printed forms were then inserted back into the printer and the specification was printed on them. They acted in the same way with an explanatory note or when drawing up a specification in Word. This method of fulfilling specifications is now extremely rare.

Features of filling out fields

Each specification field must be filled out in the prescribed order. The sequence of filling out each column is performed based on the following rules:

- The order of recording the entire document is given in the “Format” column. It displays its attributes that determine the formatting of the text. If you need to use different formats in one document, it is marked with a special “Star” symbol. This feature is noted in the note. The sequence of listing formats is determined by their ascending order. If the parts being developed or finished have no drawings or are not made well, the abbreviation BC is written in the note.

- The drawing can be made on several sheets. The number of each of them is recorded in the section called “Zone”.

- The serial number of the prefabricated structure element used is indicated in the “Position” column.

- Each identifier of documents and units is recorded in the “Designation” column. The recording rules are established by standard number 2.201-80.

- Standardized designations are noted in the column called “Name”. Designations of assembly units are placed there.

- The name of each sheet used is placed in the "Documentation" section. The following entries are used as the title: general view, assembly or dimensional drawing, additional descriptions and images.

For the correct execution of specifications for the assembly drawing, a special form has been developed. This template can be filled out using special computer programs or manually.

Experienced designers reserve free lines in each of the selected sections. They will be useful in the future when making additions and clarifications. Every competent design engineer must be able to correctly fill out an assembly drawing specification. The correctness and quality of the assembled part, its durability and reliability during operation depend on this.

Download GOST 2.201-80