An apartment, and especially a private house, needs regular maintenance and repair work. A home handyman has to be a generalist, capable of performing many different tasks. Therefore, masters want to master as many technologies as possible.

One of the most in-demand skills is the ability to perform welding work. Practice shows that electric welding is best suited for beginners - the technology is simple and accessible to anyone who wants to learn how to use it. Before you start mastering the method, you should familiarize yourself with the theoretical aspects of the issue, don’t you agree?

All the necessary information is described in detail in our article. We described the principle of operation of electric welding and indicated which device is best to choose for working at home. In addition, the article provides a step-by-step technology for welding parts, methods for making seams, and also lists possible defects in joints.

Choosing a machine for household welding

There are many types of welding today. But most of them are intended for special work or are designed for industrial scale. For domestic needs, it is unlikely that you will need to master a laser machine or an electron beam gun. And gas welding for beginners is not the best option.

The easiest way to melt metal to connect parts is to pointly influence it with the high temperature of an electric arc that occurs between elements with different charges.

Electric arc

It is this process that is provided by electric arc welding machines operating on direct or alternating current:

- The welding transformer welds with alternating current. For a beginner, such a device is unlikely to be suitable, since it is more difficult to work with due to the “jumping” arc, which requires considerable experience to control. Other disadvantages of transformers include a negative impact on the network (causes voltage surges that can lead to breakdown of household appliances), loud noise during operation, impressive dimensions of the device and heavy weight.

Welding transformer

- An inverter has many advantages over a transformer. It generates an electric arc with direct current, it does not “jump”, so the welding process is more calm and controlled for the welder and without consequences for home appliances. In addition, inverters are compact, lightweight and virtually silent.

Therefore, if you are faced with the task of learning how to cook with electric welding, then it is best to purchase an inverter machine.

Welding inverter

Tips on how to learn to cook with electric welding yourself

It is possible to weld a simple metal structure in a few hours, provided that you have already mastered the technology, planned the operations of the technological process and prepared everything necessary.

To learn how to cook correctly, you should keep the following in mind:

- You should prepare and find out the necessary information about the materials you are going to cook.

- Select the appropriate operating mode and welding materials for them.

- Study the technique of performing the specific seam you have planned.

There is little substitute for attending a professional welding school and practicing under the guidance of an experienced mentor. But if for some reason this is not available, then the correct movements, position of the hands and body when working can be well studied using training videos from authoritative welding masters.

Of course, they won’t trust you to weld the body of a nuclear reactor, but you can easily handle a frame for a gate or ladder. Starting with simple seams and learning how to weld them correctly, you can move on to more complex ones, gradually gaining experience and honing your skills.

What else do you need to have?

A welding machine without electrodes is a completely useless unit. Electrodes are a consumable material, they also come in different types: melting and non-melting, metal (made of steel, copper and other metals) and non-metallic, in the form of wire or a rigid rod, with different protective coatings, etc.

For those who are wondering how to properly weld with electrodes, it is best to start with steel universal rods 3 mm or 4 mm thick. The diameter is indicated on the package, it will not be difficult to choose the ones you need. Having mastered working with them, you can switch to other types, but they are unlikely to be in demand in everyday life.

Electrodes for inverter

In addition to welding consumables, you will definitely need a welder's mask. It is absolutely impossible to work without it, otherwise you can quickly get a burn to the cornea and many other vision problems. Masks with chameleon glass are considered the best. Or rather, with an automatic light filter that reacts to changes in illumination and protects the eyes from harmful radiation.

It is also advisable to acquire suitable clothing, shoes and gloves that are not burned by sparks and can protect against electric shock if something happens.

The tools you will need are a hammer to knock down scale from the seam, as well as all kinds of vices, clamps and magnetic corners that can be used to fix the parts to be welded in the desired position.

Minimum kit for a beginner welder

From my personal experience

Why did I say that welding has changed a lot recently? This is because equipment and technologies have seriously developed and do not stand still. Today, instead of a huge transformer that will burn out all the wiring in the house, you can buy an inexpensive inverter that consumes no more electricity than a regular electric kettle.

So, with this same inverter you can do all the work around the house: weld a barbecue and a fence, weld a wheelbarrow or shovel. With the advent of an inverter in my house, I almost gave up the use of bolts, studs and a bunch of nuts, which were previously wasted in large quantities.

Perhaps many, like me, will benefit from my modest advice and developments that I have learned over many years. Please don't judge harshly.

Basics of welding work

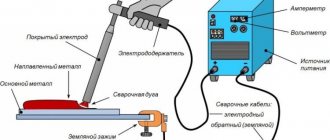

To cause the formation of an electric arc, two differently charged conductive elements must come into contact. One of them, negative, is the electrode, and the other is the surface to be welded, to which a metal clamp is connected, the cable from which is connected to the positive output of the inverter.

Electrode welding is caused by the melting of the metal by the heat generated by the arc. In order for the seam to be smooth, it should not be interrupted. So, to get started, you need to install the electrode, configure the inverter, light the arc and learn how to control it.

Electrode installation

The inverter device is equipped with two cables. A clothespin clip is attached to the end of one of them, with which it clings to a metal part. And the second cable is equipped with an electrode holder, which can be screw or spring.

Welding cables

See also: Catalog of house projects for which artificial stone was used for finishing

For the screw holder, you need to unscrew the head on the handle, and after installing the electrode in the socket, screw it back in. With a spring one it’s easier: just press the key to open the socket.

Connecting the welding machine

Welding cables are connected to the inverter through special outputs on the device body with different polarities. Which of them to attach the clamp to, and which electrode, depends primarily on the materials being welded. You need to understand this point in order to understand how to weld correctly and not get confused:

- The standard connection for welding steel parts is a minus to the ground cable with an electrode, and a plus to the cable with a clamp. It is called direct polarity and is suitable for most connections required in everyday life. Direct polarity ensures the classical movement of electrons from minus to plus, in which they transfer a significant part of the energy to the metal and heat it better.

- If you connect the clamp to minus and the electrode to plus, we get reverse polarity with a lower degree of heating. What is necessary when welding stainless steel products and in some other cases.

The arrows on the diagram indicate the direction of electron movement

Advice! It is best to master the basics of welding on parts made of ferrous metal, using a connection with straight polarity.

Now you can plug the device into the network and get to work.

Ignition of the electric arc

Before learning how to weld, you need to cause an arc to appear, for which you make short-term contact of the electrode with the metal part. This can be done in two ways: end-to-end and by striking:

- Butt ignition involves tapping the metal with the tip of the connected electrode.

- Ignition of the arc by striking is performed in the same way as lighting a match on a box.

There are no advantages to any of these methods - everyone does what he likes and is most comfortable with.

Safety precautions

Electric welding is popular. The device is small in size and is capable of hermetically connecting parts in any spatial position; welding is fast and controllable. When working, be aware of the health risks:

- Eye injury. The welding arc emits light energy, which can burn the cornea of the eye and be imprinted on the retina. A feeling of sand under the eyelids, difficulty blinking, swelling - these symptoms go away for quite a long time. A mask with special glass will help protect your eyes; before lighting the arc, warn others by shouting: “Eyes!”

- Electric shock. Electric arc is the passage of electric current through the gap between the electrode and the metal. The greater the current, the brighter the arc. But if this current passes through a person's body, he will die. To avoid electric shock, you need to: Monitor the integrity of the cable braid and the insulation of the holder.

- Use high-quality insulated holders; do not grab the bare parts of the holders with your bare hands.

- When working continuously, wear safety shoes with rubberized soles.

Video description

The methods for igniting electrodes are clearly shown in the video:

The main thing is that the movements are fast enough and the contact is short-lived, otherwise the electrode will “stick” to the metal. This happens especially often with new electrodes that have not yet been used.

At the same time, a partially spent electrode may not ignite immediately due to the buildup of the melted protective coating formed at its tip. It is easier to beat it off using the tapping method.

You can proceed directly to how to properly weld with electric welding after confidently mastering the skill of exciting an arc. But first, it’s worth understanding what is happening or should happen in the process. Without this it will not be possible to move on.

See also: Catalog of companies that specialize in working with electrical networks and related equipment

Welding process analysis

At the point where the welding arc occurs, the temperature rises greatly, as a result of which the metal of both the parts being welded and the electrode rod itself begins to melt. Liquid molten metal fills a burned-out depression, which in professional language is called a weld pool.

Schematic illustration of the electric arc welding process

At the same time, the protective coating of the electrode is destroyed, fulfilling its function: part of the coating melts, turning into slag, which covers the fresh joint and prevents the metal from contacting oxygen, and also maintains a high temperature underneath. And the other part goes into a gaseous state, creating a protective atmosphere around the weld pool, and also preventing air oxygen from reaching it.

Let's sum it up

Welding work requires special knowledge, skills and special equipment. Please note that this is a rather complex and dangerous process that requires strict adherence to safety precautions.

Welding skills require some time and practice. There is nothing wrong with training on a piece of unnecessary metal. This allows you to gain experience and understand the essence of the welding process.

Before you start welding parts, you should hone your use of a welding machine and the ability to weld seams on workpieces and then move on to more complex elements.

Video description

All this can be clearly seen in slow motion:

The slag crust from the weld is knocked off with a hammer after it has cooled.

Important nuances

The main secret of how to properly weld two parts and get an even seam is that when moving the electrode, the slag has time to cover the entire surface of the molten metal. And this depends on the speed of movement, the angle of inclination of the electrode and the trajectory of its movement. The current strength is also important.

The universal working angle is 30-60 degrees relative to the vertical. Wherein:

- moving the electrode at an angle forward (away from you), it is convenient to make any vertical, horizontal and circular seams;

- at an angle back (towards you) - weld corner joints;

- the vertical position of the electrode is allowed only when welding in hard-to-reach places;

- An angle of more than 60 degrees greatly stretches the weld pool, and the metal of the welded parts heats up worse. It is usually used when you need to trim off excess or touch up a rough seam.

The influence of the angle of inclination of the electrode on the shape of the weld pool

The welding speed is determined experimentally: it is necessary to ensure that the shape and dimensions of the weld pool remain stable and do not stretch or spread. It is very important to keep the electrode at the same distance from the surface - 3-5 mm from it. Moreover, as the bath is burned out and deepened, it must be lowered slightly, and when moving to the next section, raised again, trying not to go beyond the specified limits.

To connect the edges of two parts, you need to ensure that their particles penetrate each other. To do this, the electrode must move not in a straight line, but along a certain trajectory, oscillating from side to side. This trajectory may resemble a herringbone, ladder, figure eights, connected triangles, etc.

Options for moving the electrode tip during welding

Recommendations on how to weld metal correctly

To weld metal correctly, it is not enough just to learn how to make seams. The welder must also be a materials scientist - know a lot about the properties of the materials being welded, their interaction with each other and with high temperatures.

The technology includes many operations before and after the actual seam is completed.

Before starting the main operation, the parts to be welded must be thoroughly cleaned of mechanical impurities, old paint, rust and must be degreased. It is also necessary to correctly position them relative to each other and fix them in this position.

When connecting thin-walled structures or simply long seams, the parts are clamped to each other at several equally spaced points to avoid thermal deformation.

The future welder must know and anticipate in advance:

- potential problems;

- types of defects

and think about how to avoid them.

Start with the three simplest types of connections

- Butt. The edges of the parts to be joined are in the same plane with a small gap between them, and this gap is filled with suture material.

- Overlapping. The parts are arranged with some edge overlap.

- Tavrovy. One plate is welded end-to-end in the middle of the other, usually at a right angle.

Three main types of connection

In general, a welder's job is half welding and half planning and preparation. Learning to cook properly means learning to plan and prepare.

Welding of elements

Having confidently mastered the basics of the welding process, you can move on to connecting elements into a single structure. And here, too, there are subtleties associated with the reaction of the metal to such an impact.

First of all, you need to correctly assess the length of the seam and ensure that it does not pull the parts being connected at the joints. To do this, they must be fixed in a given position using clamps or other methods. And to secure the fixation, they are secured with transverse seams in several places. And only then are they scalded.

The welding order depends on the length of the joint. Only short seams up to 300 mm long can be welded in one direction and in one pass. If this distance is greater, it is necessary to compensate for the resulting stresses by applying stitches in small sections.

Seam patterns depending on length

When the work is finished, not very beautiful seams can be carefully cut off and sanded with a grinder.

M. Gladwell's “10,000 hours” rule

Of course, you won’t succeed in everything right away. Take it calmly. When learning to weld metal, it is recommended to follow the 10,000 hour rule developed by Malcolm Gladwell. To achieve a level of unsurpassed skill, you need to devote that much time to your craft. Yes, for most of us this is very far away. Here are the intermediate steps:

- one thousand hours to master level;

- one hundred hours to the professional level;

- and at least ten hours to master the basics - they look quite realistic!

You are at the very beginning of your journey. Train, study, and with every hour you spend studying, your skills in metal welding will become stronger. Good luck!