Today, CNC plywood milling is the most popular method in the industry. Plywood elements easily complement interior details, household items, packaging, and other products.

Everyday life, construction, industry – you can see plywood products everywhere. They have a large number of advantages, such as practicality, ease of use, ease of processing and manufacturing, good technical characteristics, and cost-effectiveness.

The main advantage of CNC milling, in contrast to format-cutting equipment, is the ability to set any trajectory, cut holes, grooves and create a three-dimensional relief.

Cutting plywood in Moscow from 1 hour!

Plywood cutting is used to create a wide variety of blanks and finished products.

The breadth of use of this sheet material is due to its physical, mechanical properties, and performance characteristics. The advantages of plywood include the following qualities:

- resistant to high humidity;

- withstands temperature changes;

- does not deform under mechanical loads;

- has a beautiful wood texture;

- has a variety of colors due to the use of different types of wood in production

Plywood is made from the thinnest sheets of wood called veneer. These layers are arranged symmetrically relative to the main sheet and glued together with special compounds. For plywood that will be used in open spaces, a special moisture-resistant adhesive is used.

A sheet of plywood consists of several veneer sheets, of which there should be an odd number. When cutting plywood, the thickness of the material must be taken into account in order to avoid damage, chips, cracks, and to create a smooth cut area.

The most valued are plywood sheets made from birch and oak wood, which have a unique texture and original color scheme. They are used for the production of products for interior decoration, the creation of exclusive advertising and exhibition structures, and commercial equipment.

For finishing premises in construction, softwood plywood is used, which is not inferior in its properties, but has a more favorable cost.

Cutting plywood is one of the technological operations in the manufacture of entire products and structural parts in the following fields of activity:

- indoor and outdoor advertising;

- installation of exhibition pavilions, stands, expositions;

- vehicle finishing;

- design of interiors and exteriors of buildings and structures;

- construction and repair;

- furniture manufacturing;

- production of packaging materials

Scope of use

Cutting plywood using milling machines is used in the construction industry. Thanks to it, floors, wall formwork, and foundations are made. Plywood is also used in:

- shipbuilding;

- roofing works;

- laying the floor;

- interior design;

- furniture production.

Using milling on CNC machines, figured cutting is created. Thanks to cutting, advertising structures are produced. Plywood has high performance characteristics. The material can be used to make small three-dimensional letters for signs.

Our equipment

- The machine is designed for fast feed up to 190 mm/sec.

- The working field of the machine is 2000x4000 mm, which allows the use of large sheets entirely.

- Ball screw guides.

- Detailed settings of cutting modes and accelerations on the control panel.

- Working sensors for axes and spindle shaft voltage.

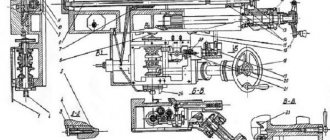

Design and operating principle

The cutting tool (mill), installed on the machine, removes the workpiece material layer by layer in the required places according to a given operating algorithm.

Regardless of the device model, its design includes:

- cutter (set of cutters);

- fastening for it (collet chuck);

- a device that imparts rotation to the tool (spindle);

- motors that move the portal along the axes (usually two-phase stepper or servo);

- gearboxes that provide torque transmission to the gear responsible for moving the portal along the X, Y axes;

- the system can be moved along the Z axis using a ball screw;

- control system;

- a number of models are equipped with coolant and an automatic cutter change unit (ATC);

- In some designs, a vacuum work table for workpieces is implemented.

Open up the plywood. Technological features

Processing of sheets is carried out in several stages, the first of which is cutting the plywood. The technological features of this type of activity lie in the structure of plywood as a sheet material.

Each sheet consists of several layers of veneer. The wood fibers in them can be located parallel or perpendicular to each other. When cutting plywood, craftsmen must take this property into account.

If it is necessary to obtain a perfectly smooth edge of the future cut, the material is cut along the location of the fibers of the top layer of plywood. The resulting blanks and structural parts fit together beautifully and look neat and aesthetically pleasing.

In some cases, for example, when creating creative interior decorations, for original decoration of premises, it is necessary to obtain the effect of fibrous cuts. Then the plywood is cut transverse to the direction of the fibers of the material.

Of particular importance is the cutting of plywood with a laminated surface. In order not to damage the laminate layer applied to the material, cutting laminated plywood should be done to a shallow depth (up to 0.3 mm) with a particularly sharp, thin tool.

Plywood cutting is carried out in production conditions on special tables that are an integral part of milling machines. Such tables have dimensions of 2m by 4m and allow you to place a whole sheet of material.

Our company has the necessary modern technological equipment to perform high-quality cutting of plywood in Moscow.

Types of milling devices

The most common and functional is the milling type. The design of the machine assumes the presence of a collet clamp. With its help, you can use cutters with different diameters with the machine.

Laser-type devices are small in size. But at the same time they have a lower power rating. Most often, such units are used for additional processing of parts in order to ensure higher accuracy.

Waterjet machines are also available. The third type of devices is represented by a vertical base. It has wide functionality and is large in size. Because of this, the device can only be placed in a room with a large area.

Milling cutting of plywood, price for Moscow and Moscow Region

| Thickness (mm): | Price (rub./linear meter) The amount is indicated without VAT! | ||

| up to 1000 | over 1000 | ||

| 3-6 | 30 | 25 | |

| 7-10 | 55 | 40 | |

| 11-20 | 80 | 65 | |

| 21-30 | 120 | 100 | |

The minimum order amount is 4000 rubles.

To ensure that plywood cutting is carried out with a guarantee of quality and in exact accordance with the provided dimensions and the developed layout, milling machines are used. The main cutting element of such a machine is the milling cutter. It moves in a given direction at high speed and cuts and cuts plywood quickly and accurately.

Cutting plywood with a milling cutter ensures the accuracy of the work, high speed, and guarantees full compliance of the dimensions and shape of the future product or workpiece with the specified parameters.

If plywood cutting is performed using milling equipment, the cost of orders is significantly reduced compared to manual processing of the material. The price of cutting plywood on machines also depends on the following indicators:

- sheet thickness;

- order quantity;

- layout complexity

Milling plywood will cost less when ordering in bulk. Our company offers favorable discounts for plywood cutting in Moscow for regular customers.

Order plywood cutting right now!

Call tel. in Moscow: +7 (906) 777-22-33 or order a calculation

What is milling

In principle, hand-carved wood can be conditionally classified as milling. But there is a clear difference - only those types of processing that are carried out using a rotating cutter on manual or stationary machines are called milling.

If we exclude other simple woodworking techniques - sawing, hewing, planing, drilling, then there are two main directions in woodworking.

- turning - carving a rotating part to give the desired shape to the diameter of the part;

- milling – the formation of linear (not radial), longitudinal shapes.

The scope of application of milled parts is limitless. Such details can be found in many complex modern products. The operation is quite labor-intensive, but sometimes there is nothing to replace it with. Casting or stamping will not give accurate dimensions, or these methods cannot produce such complex formats. The only way left is milling.

CNC plywood cutting

An important function of modern CNC machines is cutting plywood. Computer numerical control equipment performs all operations based on commands issued by special programs. The machine connects to a computer and performs work quickly and with the highest possible quality.

Milling plywood cutting using CNC machines allows you to complete orders in the shortest possible time, even with complex layout shapes, since the necessary tools are replaced without stopping the equipment. The program itself selects the most optimal version of the cutter, sets it the desired speed, direction of movement, and depth of rotation.

Thanks to the high speed and number of revolutions of the cutter per minute, it is possible to perform high-quality cuts of plywood up to 70 mm thick. In this case, the cuts are smooth, without protruding fibers. There are no cracks or chips on the surface of the material, even on laminated plywood.

Order CNC plywood cutting in Moscow from our company and quickly receive excellent blanks and finished products!

About the material

Plywood is a laminated wood that consists of 3 or more sheets of peel-cut veneer glued together. Its technical and operational properties are superior to solid wood.

There are such types of this material:

- laminated;

- polished;

- moisture resistant.

The surface of the plywood should have the same physical properties and, best of all, belong to the same species. This multilayer material is considered to be made from the rock from which its surface was made. By dividing plywood into species, its rational use increases.

There are the following methods for processing plywood using machines:

- Laser cutting. The process occurs at a high temperature of the beam, and it leaves behind dark, burnt stripes and spots. The image comes out in the form of a print, so there is no need for further processing of the outline.

- CNC plywood milling. It consists in the fact that according to a pre-developed scheme (it is done in a graphic program), an outline of the product is created, which is transferred by the program to the CNC for milling. Then the cutter rotates and, step by step, repeats the movements specified in the drawing, cutting it out of plywood.

Cutting/cutting plywood in Moscow

Plywood cutting is carried out by our company using our own high-performance equipment with numerical control, manufactured by the world's leading manufacturers. The company's workshop is equipped with machines that perform milling plywood cutting in the shortest possible time. For some orders we only need up to 1 hour!

CNC machines are operated by experienced, qualified craftsmen. We guarantee high quality products because we use only the best consumables purchased from trusted suppliers.

We accept and calculate orders according to the following requirements:

- Drawings in vector format such as dwg, dxf, cdr or ai, such programs as AutoCAD, Corel DRAW or Adobe Illustrator, PDF

- Exclusively 2D, 2.5D

- Scale 1:1

- Dimensions in millimeters

- Raster images are permitted for supporting information only.

- All curves are closed, without intersections, overlapping vectors, etc.

- All objects and fonts in curves

Cutting plywood with a router. Our advantages

We cut plywood with a milling cutter in Moscow according to sketches provided by the client, and also develop our own layouts of any complexity. Representatives of large and small businesses, government agencies, organizations in the field of advertising, exhibition business, furniture manufacturing, packaging, and interior design products cooperate with us.

Our prices for cutting and sawing plywood are affordable and competitive, since we work without intermediaries and provide the full range of services. With us you can place an order for plywood cutting in Moscow and delivery of finished products to the specified address. By agreement with the client, our employees install plywood structures.

Contact us by phone, email or fill out an online application on the website!

Working with a hand router

There are some special features when working with a hand router. Modern industry provides the home craftsman with a wide selection of hand tools that allow him to mill wooden parts with his own hands. The undisputed industry leaders are Makita, Bosh, and domestic manufacturers - Energomash, Rostec, Fiolent, etc. The choice of tool depends not only on the size of your budget, but also on the requirements for the device.

There are two main types of milling machines:

- vertical submersible;

- edge;

- combined.

The first type has great functionality and prevails among all device models. It is equipped with a collet clamp for cutters of different diameters and has a wide range of settings, including for repetitive operations.

The edge router is characterized by smaller dimensions and power. The main purpose of the device is to give the side planes of plywood sheets a neat appearance, and to cut the edges of solid wood and MDF.

Combined routers consist of a vertical base, after dismantling the device from which a compact edging tool is obtained.

A router not only makes it easier to work with wood, but also allows you to do things that are almost impossible when using other tools, for example, make a tenon to connect two wooden parts, quickly drill a hole for a lock, cut a part of a complex configuration from a sheet of plywood, or decorate its surface beautifully pattern. The main features of such automatic tools are as follows:

- profiling of cornices, platbands, skirting boards, glazing beads;

- cutting wood along a complex, curved contour;

- creating grooves, shaped recesses;

- surface decoration;

- drilling holes.

The ability to set precise settings for the cutting depth allows you to practically automate the process; you only need to manually set the router’s trajectory.

The power of a portable milling machine can range from 600 to 2300 W; the most powerful models process not only hard wood, but also some types of plastic.

The router can work with both hard and soft wood.

Particular attention should be paid to the choice of cutters, since not all of them can cope equally well with different materials.

Return to contents

How to choose the right cutter

Depending on the type of work to be done and the type of material, it is important to choose a cutter that would cope with the processing in the best possible way. The cutters differ from each other not only in design, but also in the diameter of the shank, material, size, and shape of the cutters. Their main types are as follows:

- cone-shaped cutters - designed for processing sheets of material at an angle;

- profile cutters - for creating longitudinal grooves and other linear elements;

- V-shaped - for applying inscriptions and creating holes whose walls are inclined at an angle;

- edging - indispensable when processing the edges of wood sheets;

- disc cutters - help in creating grooves in horizontal planes;

- cutter of the “swallow’s nest” type - for cutting out connecting tenons;

- fillet cutters - for profiling skirting boards, cornices, glazing beads.

In addition to classification according to the shape of the cutters, cutters are divided into bearing and bearingless. The first type is intended for stationary milling installations, so when purchasing consumables it is important not to make a mistake.

Special requirements are put forward for the storage of cutters. Due to the fact that modern cutting devices are made of very hard but rather fragile materials, the cutter should be stored separately from other tools. The ideal option is a special wooden box, in which sets of cutters are often sold. When purchasing such a set, you can pay attention to how tightly each attachment sits in its socket: sometimes you have to remove them using pliers. This is done so that during transportation the cutters are not damaged by hitting each other.

Return to contents

What can be made from plywood on a laser machine?

- Souvenir products.

- A wide range of advertising products, both large banners and small-sized products.

- Templates and patterns for designer furniture and decorative elements.

- Furniture.

- Applications.

- Business cards.

- Toys.

- Magnets.

- Nameplates and numbers.

- Postcards.

- Phone cases.

- Jewelry.

Recommendations for choosing milling equipment

- Check with managers for information about the model. In particular, information about what materials the machine works with. All our equipment undergoes triple quality control. And this process is recorded on video, which you can ask managers before purchasing the machine.

- Attend a demonstration. This can be done for free before purchasing any equipment. You can bring your workpiece to the demonstration, see how the machine works on it and ask questions about its operation.

- Check the package. When you have decided on the choice of machine, be sure to check the equipment components. There must be a software control unit for the machine, cords with connectors of the appropriate configuration and disks with software. All this and more can be done during commissioning, which is carried out in our service center by qualified engineers.

Milling machine Wattsan 0609 MINI Wattsan 0609 MINI is easy to use: a minimum number of settings and an intuitive interface. Details HERE.