An eye bolt is a device that is used for capturing, transporting and lifting loads; such a universal device is called a load-handling device. It looks like a long bolt with a round ring at the end. The design of the product is made of high-strength metals, it is especially firmly installed and fixed inside, thanks to deep slots that do not bend. The ring itself is not subject to ruptures, cracks, or bending.

The eye bolt is in great demand on the market and is almost impossible to replace with any other products.

The eye bolt is used in the following industries:

- mechanical engineering;

- agriculture;

- construction;

- shipping business.

Of course, the main purpose of the eye bolt is the reliability and safety of securing cargo, moving and lifting on board.

Features of eye bolts

Before installing the eye bolt, you need to prepare a hole, which is made using special drills, and then screw in the eye bolt itself. But it must be screwed in as tightly as possible. In order for the eye bolt to be installed correctly and reliably, it is necessary to select an identical drill.

The peculiarity of the eye bolt is that the fastenings intended for crossing or lifting loads can move in different directions, or if it is necessary to stand still (hold tightly). This is due to the round shape of the eye bolt limb. Therefore, loads can be lifted, moved or pulled using the eyebolt.

Types

These standard products can be classified as follows:

- with swivel hinge;

- elongated;

- eye bolts DIN 580.

Let's look at each type in more detail.

The eye, which has a long threaded part, can be screwed into the body of the part. In this case, the bolt itself can be tightened without problems with a pry bar or even an ordinary metal rod, since the ring is located perpendicular to the thread axis.

The so-called rigging points (bolts equipped with a rotating loop) are actively used in conditions of limited space. It is important to know that the load capacity is directly dependent on the angle of inclination of the hinge directly to the pin axis. The products can be used in any industry.

As for DIN 580 bolts, their operation does not require special skills from the operating personnel. It is enough to simply screw this standard unit into the body of the object prepared for lifting/lowering and carry out the strapping based on the slinging diagram.

Eye bolt production

Two technologies are used for the production of eye bolts: forging or stamping. The processing of steel plays a special role in manufacturing; it can be carbon or alloyed. In both cases, it is high-strength steel of very high quality. The only difference is that some eye bolts are used in any direction, others only where they are not exposed to moisture.

Carbon treated eye bolts are galvanized products. They do not rust, are resistant to weather conditions, and are easily used in water and when transporting sea and river cargo.

Alloy eyebolts are non-galvanized products that are just as strong as galvanized ones, but they can be susceptible to corrosion and rust. Therefore, they are used where they do not interact with precipitation and other unfavorable conditions for them.

Eye bolt - what to work with when transporting goods?

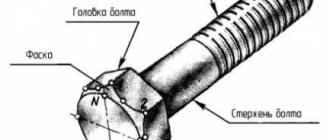

Such devices are used to attach any parts to various mechanisms and structures. A standard swivel eye bolt has the following elements: a metal rod or headless bolt and a mounting ring. For the manufacture of such fasteners, alloy or carbon steel is used, then it is additionally galvanized. Since this device is used as fastening elements, they must be strong and reliable. The design of these devices is very simple and convenient.

This makes them especially popular and indispensable in many jobs. They are actively used in port, construction and other works. Often when using ring bolts it is necessary to use various adapters. They can be either with internal or external threads, or with flanges. Adapters are selected taking into account the type of bolt. Since such devices are used either for rigging or for cable installation, they can be with a rigidly connected or rotating ring on a hinge. For each type of work, a specific option is selected.

Recently, non-standard devices for certain jobs have often been manufactured. Also ring bolts vary depending on the size. Such devices are produced with different diameters and different lengths of the rod. The higher the weight of the load, the longer the rod and the larger the diameter of the ring. The thread diameter can be from 8 to 100 mm, and the marking is indicated on the container, looks like M8, and so on up to M100. Manufacturers mark their products by impact or stamping. Since these devices are in significant demand, manufacturers are willing to accommodate and take into account all wishes and requirements.

How does each bolt come into being?

For standard fixtures, steel grade 20 or 25 is usually used. In the manufacture of these types of bolts, stamping or forging is used. The forging method is more complex, but the products are more accurate and durable. The only drawback of this method may be that the bolts may differ by several millimeters, but this deviation is allowed by GOST. The stamping method is simpler due to mechanization. Products are manufactured on special machines. The steel is heated to high temperatures and then poured into special molds.

There may be some burrs or flats on the bolt rings; this is acceptable according to the standards, and can be eliminated during the manufacturing process. Such mini-defects can be eliminated by cleaning or sharpening, but in no case by cooking. This method is unacceptable. Next, all bolts must be cleaned of scale and restored to normal condition. During the production of such fasteners, additional heat treatment is quite possible. This makes these elements more durable. These devices must not have different center holes. This will affect not only the quality, but also the strength. There should also be no cracks or cuts on the shank.

Unlike the ring, there should be no dents, burrs, or broken threads on the rod. This is a defect, and this indicator will affect the fastening in the future.

Generally, all products must undergo stress testing before being sold. Often, for this purpose, several ring bolts are taken, and a certain load is suspended on the ring; they must be left in this state for several hours. The load used is much greater than planned. If after a certain time no deformation has occurred, then the devices are considered to comply with norms and standards, and such an eye bolt (GOST 4751-73) goes on sale.

Proper handling of fasteners for successful work

Before work, it is important to pay attention to the quality of fasteners. Like any device, they must be not only durable, but also safe. They are used with large loads, so you need to follow some simple rules tested by professionals. Before use, it is necessary to evaluate the quality of the fasteners; you should not use worn or damaged ring bolts. Also, do not use devices that are bent or with deformed eyes.

It is important that the holes and threads are clean before use. Bolts that have been altered, shortened or otherwise modified must not be used. In addition to inspection, certain rules must also be observed when performing installation work. When using elements, the permissible working load must not be exceeded (usually this can be checked in special tables that are included in the package). Conventional bolts and nuts should not be used when lateral loads are required. For lateral loads, only ring bolts with either nuts or supports should be used.

It is important to use these devices at permissible working loads: usually, if the angle to the vertical is about 90 degrees, then the permissible load can be 30 percent in line, and at an inclination of 90 degrees, the permissible working load should not exceed 25 percent. Such bolts should not be shortened when attaching to weights, and before fastening, the holes must be drilled correctly to match the prepared fasteners, or washers must be used. It is important to screw in not only the bolts themselves, but also the nuts until they stop.

Even if the fasteners are attached in accordance with all the rules and checked for quality, the following safety rules must still be observed when moving the load: you cannot stand under the load while working, but you must lift it evenly, without jerking, it is important to control the lifting in such work. Ring bolts must be loaded in the plane of the eye; this should not be done at an angle. If double or more branched slings are used when working with them, it is important that the load is calculated taking into account the angle of inclination of the sling. Of course, this is a science not for the everyday level, but for large construction projects or logistics centers, where the loads are heavier and the responsibility is greater.

Classification

Nut sizes are also set according to DIN582 standards.

A marking is applied to the side of the ring nut, which provides information about the dimensions, material and manufacturer.

The size of the threaded surface varies and can be M6, M8, M10, M12, M16, M18, M20, M24, M26, M30, M36, M42 to M48. They also produce hardware of non-standard sizes, for example, M4, M5, M7, M22, M27, M33, M39, M39x2, M100. According to DIN, such parameters are not recommended to be manufactured, and they can only be purchased to order. The most common were hardware with sizes M8-M16.

Nuts are also classified:

- by type of ring - round, oval or rounded rectangle;

- according to the size of the sleeve – low or high (extended);

- by load - non-power and power;

- by type of thread - with a small metric thread, that is, when the size is indicated in millimeters, or with an inch thread, respectively, here the size will be in inches.

The inch measurement first began to gain popularity in the United States and Great Britain, while the metric system was common in Europe and Asia. Accordingly, a problem arose with the compatibility of various types of fasteners. Subsequently, Great Britain adopted metric measurement, abandoning the inch one.

In appearance, it is impossible to distinguish the American thread measurement system from the metric one, since their profile angle is identical - 60 degrees. It is possible to distinguish by markings: in the metric system, the strength class is indicated by numbers, in the inch system - by lines. Fasteners with different types of threads will never be interchangeable, since when screwed together, a gap or gap will form in the structure. The only difficulty that arises during installation of the ring nut is the correct connection of the two elements.

Depending on the type of eye-nut head, it can be of three modifications:

- A – loop-shaped head;

- B – power version, enlarged head;

- D – reduced head.