Malfunction of the fuel supply system in the chainsaw

If everything is in order with the ignition system, then we go further and check the fuel supply system of the chainsaw.

- fuel filter contamination;

- the hole in the tank lid is clogged;

- insufficient amount of incoming fuel mixture.

Disconnect the fuel hose from the carburetor and see whether fuel flows out of it or not. Fix oil leak on chainsaw | video on. As a rule, failure in how to find a defect in a chainsaw in eliminating a leak can be done with. Repairing an oil pump on a chainsaw: how to fix an oil leak for repairs. If the fuel flows in a free stream, then everything is in order - the cap and filter are working properly. If the fuel mixture does not flow at all or flows very weakly, then clean the hole in the cover (breather) with a needle.

Violation of tightness

But if you notice that oil is flowing into the chain, the cause of the malfunction may be a loose connection between the oil tank hose and the oil pump. To fix the problem, you need to disassemble the tool. If the hose is damaged, it is recommended to replace it. Sometimes it is sealed with a special compound. First, the surface must be degreased and washed. Sometimes the oil filter breaks, in some cases it becomes clogged. oil may also leak . In this case, the filter is checked, cleaned or replaced with a new one.

Carburetor malfunction

If all the actions described above did not lead to success, perhaps the reason for the chainsaw’s inoperability lies in a malfunction of the carburetor.

Chainsaw Shtil 180 oil supply repair

The STIHL MS 180 chainsaw is an indispensable tool designed for harvesting wood and other wood construction work. It is one of the most recognized gardening devices that is armed with functional capabilities.

The weight of the tool is about 4 kg. The power reaches 1.5 kW, and the bus length is 35 cm.

Note that this saw model received electric ignition and a fairly fast chain tension from the semi-professional device. saw chain from a chainsaw. you will understand why it leaks: Why oil leaks from under. In addition, the STIHL MS 180 saw has 2 tanks, designed for gasoline and for oil consistency.

One of the main features is reduced vibration.

This result is achieved thanks to 4 shock absorbers. It is no secret that high depreciation has a harmful effect on human health and Europe has been fighting it for a long time.

It must be emphasized that it is not better to disassemble this saw without the help of others without special instructions; in this case, it is better to entrust the device to the craftsmen.

Breather check

In service centers, carburetor adjustment is carried out using special equipment. For each saw, the angles of rotation of the adjusting screws are different (they are indicated in the operating instructions). The need to adjust the carburetor does not arise very often, especially if the saw was purchased from a trusted seller. All of our Husqvarna saws are sent to a service center before being sold, where specialists adjust the speed control.

We invite you to familiarize yourself with Lisianthus echo

However, failure to secure the adjusting screws sometimes occurs.

- Severe wear on the engine (pistons). In this case, it is necessary to take greater care of repairing the engine, but adjusting the carburetor can improve the functionality of the saw for a certain amount of time.

- Blockage in the carburetor due to damage to the air filter, use of poor quality gasoline and the formation of scale. In such a situation, in addition to adjusting the carburetor, you will also need to flush it.

- Severe vibration of the saw or damage to the protective cover. This happens extremely rarely, but there are still cases.

Signs that indicate the need to adjust the chainsaw carburetor:

- The engine either does not start, or starts and immediately stalls. This occurs due to the use of a poor fuel mixture.

- Significant increase in fuel consumption and emissions. An increase in the amount of exhaust gases indicates that the fuel is not completely burned. The reason for this may be fuel oversaturation.

The carburetor adjustment scheme differs for different models of chainsaws and is described in the operating instructions. However, the general principle remains the same: it is necessary to change the quantity and quality of the fuel mixture supplied to the engine cylinder.

- “L” – low, for setting low speeds

- “H” – high, for setting the upper speed

- “T” (“LA”, “S”) – for adjusting the idle speed (models that have only one screw have the “T” screw)

When adjusting the carburetor of a chainsaw, the following rules should be observed:

- Make sure the saw chain is pointing away from you

- Place the saw on a stable, level surface; the cutting part should not touch any objects.

Please note: the instructions indicate the exact angles of rotation of the adjusting screws. Strict adherence to the instructions will help avoid engine damage.

The process of adjusting the carburetor itself includes two points: basic (with the engine not running) and final (with the engine warm and turned on).

Do not underestimate the breakdown of this chainsaw assembly. If the muffler becomes clogged, the saw will lose power and, of course, will not start. If the muffler is dismountable, then we disassemble it, inspect it and remove all carbon deposits. In some models, the muffler will have to be unscrewed; after washing, the non-removable muffler should be dried with a hairdryer.

Please note: carbon deposits contain carcinogens that are dangerous to human health; dry cleaning is unacceptable as it can lead to inhalation of these harmful substances. When we remove the muffler, we plug the engine exhaust hole with a clean rag.

The reasons why the muffler may become clogged are:

When we remove the muffler, we plug the engine exhaust hole with a clean rag. The reasons why the muffler may become clogged are:

- Using the wrong fuel mixture (too much oil)

- Using the wrong oil (oil not for two-stroke engines or poor quality oil)

What kind of oil to fill for the Stihl 180 chainsaw (stihl 180)

- Don't spare money on original oil. Stihl HP 2-stroke oil costs a little more, but cleaning costs even more.

- You need to pour high-quality fuel into the fuel, you can use Mobil 1, and three-phase is suitable for lubrication; under no circumstances should you pour waste oil into it.

- Of the inexpensive options, mineral oil is 15-40, in winter 10-30. You can use M8, for example, or M10.

Remember personal safety when working with a chainsaw.

Remember that the performance of the chainsaw is affected by the quality of the oil being poured. Advantages of the Husqvarna 240 chainsaw. Why does gasoline leak from the Husqvarna 240 chainsaw? Poor quality oil can cause the tool to operate ineffectively and adversely affect its parts.

To ensure that the STIHL MS 180 oil pump delivers oil without difficulty, check and clean the pump periodically. OIL IS LEAKING Oil is leaking from the chainsaw. A brief overview of why there is oil in a chainsaw. Thus, the oil supply process will be normal.

Troubleshooting Circuit Problems

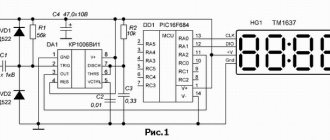

The main unit of the system is the pump. The principle of its operation follows. When the engine speed increases, a transmission mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft exerts a certain pressure in the oil line, which forces the oil to move along it in the direction of the tire.

Read:

The end of the oil channel is located where the tire touches the body of the tool, where there is a longitudinal groove into which its oil channel fits when the tire is installed.

The groove is necessary to ensure the supply of oil to the tire, regardless of the degree of tension of the chainsaw chain. Simply put, no matter what position the tire is in while running, oil will flow through it through the groove.

Then the chain is included in the lubrication process, on the links of which, depending on the chain model, there is either a groove or a hole through which the oil is dispersed throughout the tire. As the engine speed increases, the oil flow rate also increases.

READ How to Adjust the Carburetor of a Chinese Chainsaw

STIHL MS 180 carburetor repair

Repairing a STIHL MS 180 carburetor is a very difficult process. Note that during repairs there is practically no risk of sudden changes in the cylinder-piston group.

If the chainsaw does not start, then follow these steps:

1) open and close the gas tank cap;

2) it is advisable to remove the candle and then dry it;

3) ventilate the combustion chamber.

If after this there are no positive results, then it is better to check the condition of the air filter, the gasoline supply process and the functioning of the spark plug.

This problem is associated with a valve (slepun), which becomes clogged, and as a result a vacuum is formed. Everything about repairing a chainsaw with your own hands. My chainsaw is leaking oil for no reason. To eliminate this inconvenience, you need to clean the valve (slepun) with a needle.

Systematically check the filter; if the muffler is clogged, the device will not be able to deliver the power that is put into it.

If the chainsaw was purchased with a warranty (as a rule, there is no other option), immediately take it to the service center.

Thus, the STIHL MS 180 chainsaw is very easy to use, has good ergonomics and a number of significant advantages.

Saw manufactured in 2010. It is used mainly in the country and on annual trips to Karelia in August. I wouldn’t say that I completely trashed it; rather, it was used sparingly and sparingly. I didn’t build her a house from timber. So, fell the tree, saw off the pillar... And for a year now I have been suffering from this problem: there is always a puddle of oil under the saw. Leaking from the chain lube reservoir. I changed the pump 2 times, changed the rubber band into which the pump piston is inserted - one hell of a leak. In the summer, a full tank can leak overnight. After a long period of experience, I established that the leak was not from the pump, but from under the metal strip, which is under the “tire”. Behind it at the top there is a hole with a piece of PVC pipe inserted into it, which goes into the oil tank.

So, it constantly flows from there. I tried to leave the saw on its side, and twisted it this way and that... No matter what you do, there’s a puddle under the saw. Has anyone encountered something similar? Is it really possible to cure or will I continue to suffer forever? Nothing was flowing before...

TOP 5 popular brands

Saving on lubricants leads to accelerated wear of chainsaw parts, and even to its breakdown. We have already noted that under no circumstances should you consume waste liquids - this is a sure step towards destroying your instrument. It is not recommended to fill in diesel oils, spindle and other substitutes. They are not suitable for such purposes and have a bad effect on the performance and durability of the chainsaw.

Husqvarna Chain Oil

Oleo-Mac Polar Lube

The constant use of substitutes accelerates chain and bar wear by 30-40%. When recycling is used, this figure rises to 60-70%. Decide for yourself whether it makes sense to save on oil to lubricate the chainsaw chain.

Faulty cylinder and its piston group

You can suspect a problem when the engine is not running at full power. In addition, it may not start, since low pressure will be generated in the cylinder. In order to accurately identify the cause of the malfunction, check the crankshaft bearings, cylinder pistons, and the cylinder itself. All these parts can wear out. To study such parts of this unit, first remove the muffler. The review will be limited, but it will be enough to understand the condition of certain parts.

The chain is jammed

This happens when the drive or driven sprocket wears out. The chain usually starts to jam under load. But without load the saw can rotate. The photo below shows a worn chainsaw drive sprocket.

READ How long does gasoline and chainsaw oil last?

The next photo shows that the reason why the chain jams must be looked for at the location of the driven sprocket.

But what to do if the chainsaw is completely jammed, and all attempts to pull the starter are unsuccessful? This malfunction sometimes occurs on Chinese-made chainsaws. It is caused by the bolts that screw the engine to the plastic casing of the unit becoming loose due to vibration. These bolts are located directly under the flywheel (magneto). In the photo below, arrows show the location of the problem bolts.

As they unscrew, they begin to rub against the flywheel and can completely jam the chainsaw. The following photo shows the flywheel with some scuff marks from the bolts.

To fix the problem, you will need to remove the flywheel from the engine shaft and tighten the bolts.

Lubrication system breakdowns that you can fix yourself:

The oil line has broken. The most difficult thing is to diagnose this breakdown. But if you still manage to detect a break or an area of oil leakage, you can simply replace the worn part; Chainsaw oil line Oil pump

- Clogged filter or oil line. There are no special problems here either; clean all parts thoroughly and replace them if necessary. We recommend cleaning the oil line with compressed air;

- Worn thread on the oil pump shaft. In this case, only replacing the part will help;

- Oil pump malfunction. The most complex failure. It can be solved by repairing the unit or replacing it completely.

Chainsaw loses power under load

If during operation the power of the saw disappears somewhere, then the problem should be looked for in the following places:

- In the muffler. It, as you already understood, tends to get clogged.

- In a clogged fuel filter.

- A poorly functioning fuel pump.

The chain breaks

If the chain breaks while the chainsaw is running, this could happen when it hits a hard object, such as a nail. If the chain constantly breaks, then the reasons may be the following.

- Low quality of the metal from which the saw chain is made. It is necessary to buy gas cutter saws from reputable brands.

- Chain overheating due to poor lubrication. As a result, the saw overheats, the properties of the metal change, and it breaks under load. It is necessary to check the entire chainsaw lubrication system (discussed above).

You can also learn about the reasons for frequent circuit breaks from this video.

Removing the flywheel and clutch

In order to unscrew the flywheel nut, you need to unscrew the spark plug and install a piston stopper in its place.

Once the piston stopper is installed in the cylinder, the flywheel nut can be loosened. After the nut is unscrewed, it is necessary to use a hammer and a drift made of soft material to apply one sharp blow, installing the drift on the flywheel mounting shaft. This is necessary to remove the flywheel from the shaft, since the design provides for the installation and tightening of this element with great force.

You can learn more about how to properly remove the flywheel from a Husqvarna chainsaw, as well as how to completely disassemble the saw by watching the video. The wizard explains the entire process step by step and demonstrates all the necessary tools:

In order to unscrew the clutch you will need a special key. If there is no key, then it can be made from an old twenty-two head, grinding it in a certain way using emery.

Do not try to unscrew the clutch with a hammer and chisel, as some craftsmen advise. Using these tools, you risk breaking the clutch housing and increasing repair costs. It can also damage the crankshaft bearings.

Removing the Husqvarna front handle is quite simple, as it is attached to the shock absorbers with screws.

Sources:

https://stroy-dvorik.ru/pily/techet-maslo-iz-benzopily-shtil-180.html https://armatool.ru/tec-masla-na-benzopile-ustranenie-neispravnosti-i-fotootcet/

Reasons why it takes away from a straight cut

Sometimes situations arise when it is almost impossible to make a straight cut with a chainsaw; the tire moves to the left or right. The reason for this behavior of the tool may be the following:

The inability to make a straight cut with a tool is a sign of increased wear of the bar and chain, which in turn should be sought for its cause. Eliminating the effects of wear by replacing consumable parts will not bring the desired result, because... If the lubrication system malfunctions are not eliminated, after a while everything will repeat itself.

The main reasons for a crooked chainsaw saw

If a chainsaw begins to cut crookedly during operation, then in addition to an uneven cut we get a number of the following negative consequences:

- The sawyer must exert physical effort to keep the tool in a straight direction.

- Fuel consumption increases, which is associated with an increase in the trajectory of the tool through the material being cut.

- Increased load on the drive sprocket, which leads to accelerated wear

- The tire wears out as the load increases on only one side

- Reduces tool performance

- Obtaining a cutting curve. If timber is being prepared for the production of boards, then crooked trunks are considered a waste. If a tree is cut down for firewood, then in the end cutting a curved-sawn log will not be very convenient

- Discomfort at work. the master gets tired quickly when working with a faulty tool

Why can a chainsaw cut trees crookedly? Many may think that the reason is a faulty chainsaw bar, but in fact there are four main reasons:

- Incorrect or uneven sharpening of teeth

- Using a chain, bar or sprocket with the wrong pitch

- Saw head wear. often due to abrasion on one side of the bar

- Improperly tensioned chain

Severe saw blade wear

The tire lasts much longer than the chain. However, this does not mean that you can use it forever and not think about replacing it. Usually the guide is changed after 2-3 worn chains. Before replacing the chain saw guide, it is necessary to assess its technical condition. If you install a Chinese-made tire on a chainsaw, it may wear out faster than the chain. Therefore, when a curve

sawing with a chainsaw, it is necessary to diagnose the tire.

Remove and inspect the tire to ensure it is worn. Wear usually shows up as shortening on one side. Sometimes this is extremely difficult to detect visually, so you need to use a caliper. A difference of a few tenths of a millimeter means the tire needs to be replaced. There is also an easy way to check rail wear using a square. To do this, the tire is placed on a flat surface, and a square must be attached to its side. If the upper and lower walls of the guide are in contact with the square, then the part is in good condition.

Accelerated tire wear can occur due to a faulty oil pump. If lubricant is supplied with long interruptions, friction increases accordingly, which means parts wear out faster. If the lubrication mechanism works properly, this significantly increases the service life of not only the headset, but also the entire tool.

How to avoid incorrect sharpening

To prevent crooked cutting due to uneven sharpening, you can use a special sharpener to straighten the chain from time to time or in case of serious damage. Buy a machine and sharpen it yourself or send it to a workshop for sharpening.

The fact is that when sharpening the machine is adjusted according to the most worn tooth, which has the smallest size among all. After sharpening, all teeth will have the same size, which will be equal to the tooth on which the adjustment was made.

Using the wrong chain

It's no secret that a chainsaw bar, like a chain, has several basic characteristics, one of them. width of the groove for installing the chain. The groove width can have several basic dimensions:

- 1.1 mm;

- 1.3 mm;

- 1.5 mm;

- 1.6 mm.

Imagine we take a 1.1mm wide chain and place it on a bar with a 1.3mm slot. Initially, having pulled well, we may not notice the differences, but as soon as the tension loosens a little, a gap of 0.2 mm will prevent it from moving evenly along the tire, it will tilt to one side and we will again get a curve

lumber

You can check the chain width with a caliper.

To fix the problem, if the chainsaw bar is not yet badly damaged and there is no uneven wear on it, you only need to replace the chain. If it is already showing wear, a completely new set will need to be installed.

Typical malfunctions of saw chains and bars: causes and characteristic symptoms

The article provides examples of common breakdowns and malfunctions of the sawing apparatus (bars and chains), with photos of damaged parts and an analysis of the causes of the breakdown.

Now you can find out what signs experts use to determine whether your case is covered under warranty, and why their reviews about the causes of the breakdown are often so categorical. It's simple - the vast majority of violations of the chainsaw operating rules (poorly tensioned chain, dry operation or a dull chain) cause breakdowns with characteristic external signs.

The material was prepared by Stihl (Calm) for service center specialists and kindly provided by the editors.

A small retreat

Very often we are asked the question: “Why does a chain mounted on a saw move but not cut? This is usually influenced by four factors: