One of the essential elements of a chainsaw is a tire. It is also called a chain guide, and over time this part wears out. If it malfunctions, it is not recommended to operate the tool, as this may lead to injury. The chainsaw tire cannot be repaired, so after failure, it must be replaced. What types of chainsaw guides there are, how they differ, and how to choose them correctly are analyzed in detail in the material.

Tire design features

The chainsaw saw set includes a bar, which is a high-quality steel part with an elongated oval shape. One end of the guide has a corresponding cutout for threaded fastening. The second end or end portion has a built-in sprocket called the driven one. The appropriate guide design ensures smooth running of the chain, thereby reducing the load on the tool motor.

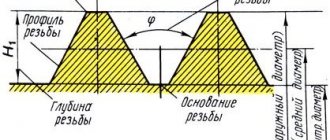

There is a groove or groove along the circumference of the bar in which the chain shanks move. As the chain moves, friction occurs, causing the surface of the bar to heat up. To reduce the effect of friction and reduce the heating temperature, a dosed amount of special oil is supplied to the working area. If the oil pump breaks down or the oil in the tank runs out, the heating temperature of the guide increases, thereby increasing the wear rate of these parts.

This is interesting!

The length of the bar depends on the power of the tool. High-power chainsaws use long guides designed for cutting trees with a large trunk diameter. Medium and low-power units are equipped with short tires designed for clearing the trunk of knots and cutting down trees of small diameter.

Chainsaw bar design

The bar is an elongated oval-shaped steel part that serves as a holder for the saw chain. The part serves as a guide for the chain. At one end it has a seat and holes for a threaded connection.

On the opposite side there is a driven star, necessary for balanced rotation of the chain. This design ensures smooth running of the chain and minimizes the load on the motor.

There is a groove along the entire perimeter of the product into which chain shanks are installed. There are special holes inside the product for lubricant and air passage. Air circulation is necessary to cool moving parts.

About the width of the groove on chainsaw tires

Before you find out the sizes of chainsaw tires, you need to remember that tools are classified into three types - household or amateur, semi-professional and professional. Depending on the type of tool accessory, chainsaws use guides with corresponding groove width dimensions.

- The groove width of the guide of a household chainsaw is 1.1-1.3 mm

- Semi-professional tools are equipped with devices whose groove width is 1.3-1.5 mm

- Professional units work with tires with a groove width of 1.5-1.6 mm

The reason for overheating of the headset may be a mismatch between the size of the chain shank and the width of the tire grooves. If the chain overheats, this will cause it to stretch, and as a result, it may burst during use of the tool.

This is interesting!

The cause of overheating of the headset may also be a mismatch between the chain pitch and the chainsaw drive sprocket.

The normal functioning of the tool also depends on the serviceability of the drive sprocket. This sprocket is not lubricated during operation of the tool, which entails accelerated wear. The rapid failure of the driven star is compensated by using a high-quality bearing. To extend the life of this important part of the chainsaw guide, it is recommended to apply lubricants every 8-10 hours of operation.

Types of chainsaw guides

When studying the features and design of chainsaw tires, it should be noted that they are divided into types. The following types of chainsaw guides are distinguished:

- Narrow flat - used primarily on household tools, and only with low-profile types of chains. They represent a narrowed nose or end part of the guide. The main advantage of the narrow-flat tires under consideration is that they minimize the level of danger from reverse impact. This is especially true for novice sawyers

- Lightweight type - consists of two steel plates, which are interconnected by a polyamide layer. This design affects the weight of the tool itself, so the work performed by the sawyer is done quickly and easily

- With the ability to replace the head - used only on semi-professional and professional high-power tools. They are designed to perform large-scale work and are characterized by increased resistance to high temperatures. The nose part changes along with the sprocket

If you are choosing a tire for a chainsaw, then you must first take into account the type of guide. When choosing, you need to start from what type of chainsaw you are purchasing the part for.

Chainsaw bar length - what they are and what it affects

One of the most important parameters of a chainsaw tire is its size. The longer the guide, the larger the diameter of the logs you can cut with the tool. However, this does not mean that you can install a long guide on a low-power chainsaw and cut thick logs. The length of the tire must have a relationship with the power.

This is interesting!

The technical description for each tool model indicates the optimal tire length that the manufacturer recommends to use.

Installing a smaller or larger part will lead to accelerated wear of the saw set and tool mechanisms. If you cannot find the technical data sheet for the tool, then you can find out the recommended length for a specific tool model in a simple way - measure the old guide. Not many experts know how to measure the length of a chainsaw bar. To find out the length of the guide on a chainsaw, you need to use a tape measure and measure the distance from the end (nose) to the beginning of the cutout. The diagram below shows how to correctly measure the length of a tire.

You can also find out the length by the description, which is usually shown on the side of the headset. However, over time the tool is used, the inscriptions become erased, so this method is appropriate for cases when the information on the tire can be read. By measuring the length, you can purchase the appropriate size saw set for the tool. Why can’t you use a long bar and chain on a low-power saw? There are enough reasons for this, and they can be described in the form of a list:

- Lack of engine power, which will affect sawing speed

- Increased fuel consumption due to increased load

- Rapid wear of the engine and consumables

- Incorrect cycle of oil supply to lubricate the chain, which will lead to overheating of the headset and rapid failure

If you do not want the tool to quickly fail, then you need to use a saw set of the appropriate size. To ensure maximum efficiency and performance of the tool, it is necessary to select the correct bar and chain depending on the power of the tool. The unit of measurement used to indicate length is the inch. Below are the dimensions of chainsaw guides in inches, converted to the metric measurement system:

- 10 inches - 25 cm

- 12 inches - 30 cm

- 14 inches - 35 cm

- 16 inches - 40 cm

- 18 inches - 45 cm

Only after the length of the chainsaw bar has been determined can you begin to select a new part. There are also devices with lengths of 38, 33 cm and others. The length of the part is 45 cm - this is still far from the largest option. Professional high-power units are equipped with devices whose length reaches 75 cm.

Chainsaw bar length

The saw bar can have different lengths. The parameter should be selected taking into account the motor power and drive torque. When choosing, you should consider the following features:

- For low- and medium-power chainsaws, headsets 30-40 cm long are optimal.

- Longer tooling increases the load on the engine and transmission units. This may reduce performance and service life.

- The chainsaw data sheet indicates the optimal length of the part. Do not exceed the recommended range. You can install a shortened tire, but this may limit the scope of application.

- A professional chainsaw can be equipped with a bar up to 75 cm long.

As a rule, the length is indicated on the surface of the product itself. The parameter can be indicated in inches and centimeters.

Wide and narrow guide groove and how it affects tool performance

In addition to the length, one must also take into account such a criterion as the width of the grooves. How does it affect the tool's performance?

- The wide groove on the guides can withstand heavy chain loads. Tires with large groove widths are used on professional and semi-professional tools

- Narrow grooves are used on low-power household and semi-professional units that are designed for light loads

It is important to select the correct chain option for the appropriate groove width.

The dangers of buying cheap Chinese tires

The materials stated that the tire is one of the most important parts of the tool. If this part fails, then using the tool is extremely dangerous. At any moment, the chain can jump off the guide and cause serious consequences. It’s a different matter when a new tire has just been purchased and installed on the tool. Its disadvantage is that it was not purchased in a company store, but on the market under an unknown brand and at a very low price. Finding a cheap tire for a chainsaw today is not difficult, but is it worth buying such a headset? Of course not, and here's what it can lead to.

- First of all, non-original products wear out very quickly, which leads to the need for frequent replacement

- At the same time as the guide, the chain wears out and must also be replaced.

- During the operation of a fake guide, a phenomenon such as wear of one side part is often observed, which ultimately leads to the inability to make an even or straight cut.

- Violation of the integrity of a part is the most difficult and dangerous case, since breaking the tire will cause a break in the chain rotating at a speed of over 10,000 rpm

That is why manufacturers recommend not saving on the purchase of a saw set for a chainsaw, and buying only branded and high-quality tires and chains from trusted sellers. After all, a person’s life depends on the quality of these parts.

This is interesting!

Work with a chainsaw should be carried out exclusively in special protective clothing.

The best manufacturers of tires for chainsaws

When choosing a guide, you should give preference to famous brands. Most chainsaw manufacturers also produce tires for their equipment.

- The greatest demand is for guides from brands such as Stihl, Husqvarna, Makita, Bosh and the like.

- In the middle and high price segments, removable equipment from Oregon is also very popular.

Experts do not recommend buying cheap Chinese tires from little-known manufacturers. Such guides often become unusable prematurely. A low-quality part may become deformed, which can result in serious injury. Non-original products wear out quickly, so it is not advisable to save.

It is recommended to purchase only original guides and other replacement parts from reputable manufacturers. Skimping can lead to injury and poor chainsaw performance.

How to distinguish a tire for a household and professional chainsaw

It will not be difficult to distinguish a household chainsaw from a professional one, since in addition to dimensions and weight, these tools differ in the shape of the guide. Household gasoline saws are equipped with tires with a narrowed nose. This design is designed specifically for beginners, since such a tool minimizes the negative effect of kickback.

On professional and semi-professional chainsaws, the toe has a wide part. If you touch the wood with the toe of the guide at high speeds, a kickback will occur. This phenomenon is very dangerous, as the sawyer can drop the tool from his hands, resulting in serious injury. Professionals and sawyers with extensive experience can use such tools.

This is interesting!

There are cases when a chainsaw has a sprocket with a standard pitch, and the guide and chain were purchased with a pitch of 3/8, then you can get out of the situation by replacing the crown. To do this, the chainsaw must have a collapsible drum on which you need to replace the crown, installing it with the appropriate 3/8 pitch. If the chainsaw has a non-separable drum, then you will need to replace it with a collapsible one.

How to extend the service life of equipment

On average, the service life of a high-quality chainsaw bar is at least 3 replaced chains. The leading star needs to be changed depending on its condition. The service life of the guide quickly decreases if the oil pump is malfunctioning, the chain teeth are not sharpened for a long time, and also if the tool is used with an unadjusted chain tension. The main reasons for accelerated wear of the device are also:

- Rapid wear of the groove and tail of the chain

- Weak or excessive chain tension

- Inconsistency between the pitch and the drive sprocket crown

- If you use the tool to cut frozen or hard wood

- When using a low-quality chain lubricant

If soil or sand gets into the groove of the guide, this leads to accelerated wear of the headset, so it is recommended to start the tool so that the chain does not come into contact with the ground.

This is interesting!

All standard professional-type chainsaws are equipped with drive sprockets with a pitch of 0.325.

How to choose a tire for a chainsaw - tips and tricks

When purchasing a new tire for your chainsaw, it is important to initially pay attention to the material from which the part is made, as well as the quality of the product and the presence of markings. The absence of markings indicates that the headset was manufactured underground, and it is not recommended to purchase such a part. When purchasing a guide for a chainsaw, you should also pay attention to three main parameters:

- Tail part - this part of the part may differ for different models of chainsaws, so make sure in advance that the part is suitable for your tool. The shank of the guide must match the shape of the chainsaw seat. If you install a guide that does not match the shape of the seat, then oil will not be supplied to the chain, which will lead to accelerated wear of the headset

- Groove width - depends on the type of chainsaw accessory and its power

- Driven sprocket - it is better to buy guides that are equipped with all-metal sprocket options, especially if you plan to saw hard trees

- The pitch of the guide and chain must be the same as the drive sprocket. If the pitch is different, this will lead to unstable operation of the engine and rapid wear of the headset. If the sprocket pitch is 0.325, then the chain and guide should have a similar value

When purchasing, also take into account the recommendations presented in the material, that is, tire type, length, groove size.

Criteria for choosing a tire for a chainsaw

When choosing, you should first of all focus on the material of manufacture and markings. If there is no marking, it is probably a counterfeit product of low quality.

Next you should focus on the characteristics:

- Shank. It is important that the design of the tail section matches the seat of the chainsaw. If the shape does not match, there may be a lack of lubricant, which accelerates wear of the cutting element.

- Groove width. Determined by the power of the chainsaw.

- Guided star. It is recommended to buy a product with an all-metal star. This sprocket can withstand increased loads and is suitable for sawing hard wood.

- The pitches of the bar, chain and sprocket must match.

- Length. Selected according to engine power and operating conditions. The recommended length is indicated in the technical specifications of the unit.

How to install a bar and chain on a chainsaw and adjust the tension

Removing and replacing a tire on a chainsaw is not difficult even for a novice sawyer. Replacement instructions are as follows:

- Using the special wrench that comes with the tool, unscrew the two fastening nuts

- After this, the protective casing, which also serves as a hand brake, is dismantled.

- Removing the chain from the tool

- The part is removed

A new tire is installed in place of the removed guide, after which assembly is performed in the reverse order of removal. At the final stage, it is necessary to adjust the chain tension. To check the degree of tension, pull the chain in the middle of the guide. Correct adjustment is when the output of the shank does not exceed 2/3 of its height. You can make sure that the chain is not overtightened by moving it along the bar, applying a little force.

This is interesting!

To increase or decrease the chain tension, you need to loosen the two fastening nuts and rotate the tension adjusting screw.

On all models of chainsaws it is located in different places. After adjustment, you need to tighten the fastening nuts. Upon completion of the work done, all that remains is to start the engine of the tool and check its operation. The chain should not make a ringing sound, which indicates its correct functioning.

Installing and adjusting the chainsaw bar

The guide is replaced as follows:

- Unscrew the 2 fastening nuts on the chainsaw.

- Remove the protective cover. The part simultaneously functions as a hand brake.

- Remove the saw chain.

- Remove the tire from the seat.

- Install the new tire into the mounting grooves and reassemble.

After replacement, the chain tension is adjusted. To check the tension, you need to pull the chain approximately in the middle of the bar.

The exit of the tail part should not be more than 2/3 of its length. Adjustment is made by rotating the adjusting screw with the fastening nuts loosened. After adjustment, the nuts must be fully tightened.

If the saw cuts crookedly - reasons and what to do

Often sawers are faced with the fact that at one point the saw begins to cut crookedly. This not only causes inconvenience, but also complicates the sawing procedure. The sawyer has to make efforts not only to hold the tool, but also to level it. Few people know that using a tool with such deformation is prohibited. Let's find out what causes uneven cuts with a chainsaw, and why this is dangerous for the sawyer.

If the saw begins to cut crookedly, this indicates the presence of subtle deformation of the tire. The deformation is associated with the tire bead, which has uneven wear. As a result, the chain is not positioned evenly, but with a slight misalignment. The amount of distortion may not be visible to the eye.

This is interesting!

The cause of an uneven cut with a chainsaw may be uneven wear on the chain links or improper sharpening.

Before replacing a tire, make sure that the chain is in good condition. The problem of uneven tire wear can be eliminated by replacing it. It is almost impossible to uniformly grind the sides of the guide, so it is recommended to replace it along with the chain. The danger of using a deformed chainsaw guide is that the chain shank may jump out of the groove, which will entail not the most favorable consequences.

The chainsaw bar, like the chain, experiences heavy loads, so it wears out. When wear occurs, it is important to replace the part in a timely manner without waiting for adverse consequences. How to choose and what to consider when buying a tire for a chainsaw is described in detail in the material.

Uneven cut

Users often experience that their chainsaw cuts wood unevenly. This not only reduces productivity and convenience, but also leads to security risks.

Typically this occurs due to tire deformation. The guide bar groove may wear unevenly. This results in an uneven chain position. It is not always possible to detect such a tire defect by eye.

The problem may also be uneven wear on the chain links. If the teeth are not sharpened well, the saw may also cut crookedly. Therefore, diagnostics should begin with replacing the circuit.

If a chainsaw with a known high-quality chain cuts crookedly, you should replace the bar. Even with careful use, it is impossible to ensure uniform wear of the groove. It is dangerous to operate such a chainsaw, since the chain shank may spontaneously jump out during operation.