In our age of dominance of various electric tools, a mechanical drill has been forgotten by everyone. Only a few of the masters of the old generation have preserved rarities: in their workshops, hand-held devices of various models are kept in a place of honor - greetings from the last century from the USSR. However, mechanical hand drills remain the most economical, practical and autonomous, compared to their descendants - electric models. You can work with a hand drill anywhere, even on a remote hunting ground in the taiga; they only require skilled hands.

Advantages of mechanical tools

The main advantage of a hand drill is its simple design and the unique reliability of all parts made of very durable metals. It is quite difficult to break something in this design, which is why it differs from the electric model. There are many examples of such a product serving well for several generations of craftsmen.

It is a hand drill that does an excellent job of drilling in such delicate materials as drywall, fiberboard, fragile plastic, various types of wood and plywood. It can be used on the roof or attic because it does not require an electrical connection.

This simple tool has excellent performance when tightening and unscrewing various threaded fasteners: screws, self-tapping screws, screws - you just need to insert the appropriate bit into the chuck. An advantage of the device is the low cost of such a tool: no more than 1 thousand rubles, making a hand drill accessible to all segments of the population.

In medicine, a hand drill is widely used for specific processing of bones and installation of knitting needles in them - model DR-2.

Advantages and disadvantages

Each tool has its own advantages and disadvantages. The product in question has the following disadvantages:

- Physical strength required to perform drilling work. Nowadays, it won't hurt to work your muscles sometimes

- Length of the product. When working, such a tool is convenient, which cannot be said about its transportation.

- Heavy weight, which sometimes exceeds the mass of electric analogues

Hand telescopic drill used in medicine

Among the advantages we should highlight:

- There is no need to connect the tool to an electrical network. The device operates depending on the user’s physical strength

- Low cost, even today manual modifications of drills are produced, the cost of which does not exceed 1000 rubles. However, the quality of these products is inferior to those that were produced during the USSR.

- Simple design. The simplicity of the design affects the cost of the unit, which is already low, as well as reliability. The simpler the design of the tool, the more reliable it is, and you can repair it yourself

This is interesting! The mechanical type drill was invented during the Neolithic era, and the electric one first appeared in 1867.

Types of designs

Experts divide mechanical drills into two main types.

- Product with one rotation speed.

- Manual two-speed design with a special gearbox.

Developers from different countries have been struggling with the problem for a long time: how to make a simple hand drill work at two speeds. For these purposes, a two-stage multiplier was invented - a gearbox of an original design, which has a set of gears arranged on different axes in a single housing.

To switch the drilling speed, you need to move the rotation handle to the other side. The gear ratio of the gearbox increases or decreases, and the number of revolutions of the cartridge per rotation of the handle changes accordingly.

Models are produced where there is no need to move the handle - the speed is switched as a result of the longitudinal displacement of the axis of rotation of the handle.

The main difference between this model is the gearbox: it is closed and located in a special housing, but, as in the first option, it can be easily disassembled, all parts are accessible for cleaning and lubrication.

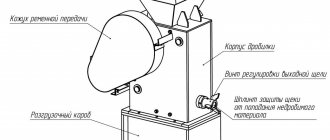

The figure below shows a two-handed version of a hand drill:

Design features of devices

The rotary and manual varieties of drills differ in design from each other, but perform the same function. If in a rotator the moment directly depends on the number of rotational actions by a person’s hand, then in hand drills this value is 2-4 times higher at the same speed of rotation of the handle.

Hand tools are divided into one- and two-speed. The two-speed hand drill is equipped with 4 gears. It is through these gears that the torque decreases and the speed of rotation of the cartridge increases, at a time when a person applies a force of equal magnitude. To change the rotation speed, you need to change the drive shaft.

Design features of a two-speed manual drill

This is interesting! A single-speed drill has only two gears with different numbers of teeth. Due to this difference, the torque decreases and the rotation speed of the cartridge increases.

The main structural elements of a handmade product are:

- Gears in the amount of 2-4 pieces

- Lever

- Drill chuck

- Handle used as additional support

- Stop foot

The principle of operation of such a product is very simple, and even a child can use the tool. When the handle rotates, a large diameter gear with a large number of teeth moves. A large gear, called the drive gear, drives the driven gear, which is several times smaller than the previous one. This is how the torque changes downwards, with an increased speed of rotation of the shaft to which the cartridge with working attachments is attached.

Polish-made hand drill: this is what this tool looks like

The ancient progenitor - the bracelet

The rotator, an analogue of a hand drill, which was invented by our distant ancestors, is not outdated, it is too early to write it off. It can be useful for unscrewing a “recalcitrant” screw or a stuck screw. To do this, you just need to sacrifice the old screwdriver and use muscle force.

The design of the rotor is extremely simple. It consists of two parts: a frame and a simple device for attaching a drill (chuck). In the picture below you see a wonderful example of Soviet industry for domestic use. The frame is specially bent and forms an incomplete rectangle; on the side there is a rotating handle, with the help of which the entire structure rotates smoothly around its axis.

Pressure is applied to the upper hemispherical handle; it also rotates freely without interfering with drilling. The same principle applies to a drill for drilling holes for winter fishing or holes for seedlings in a garden plot, which you can construct with your own hands. You can learn how to make a simple bracelet, for example, from this video:

How to use a mechanical drill

Safety rules are observed when working with any tools, including hand tools. They are no less dangerous than electric ones if used incorrectly. To avoid serious injury, follow these guidelines:

- Securely fix the part to be processed

- When drilling, the drill heats up, so you need to pause periodically to let the bit cool down.

- It is recommended to use the product with safety glasses

The simplest design of a mechanical drill

Now we know what a hand-held mechanical drill is, what it is needed for, and how to use it correctly. If you are planning to recycle a tool, you should think twice about it. Even if this material does not convince you to keep the tool in your set, it can be sold for a reasonable price of up to 600 rubles, depending on the model. You can buy new products in online stores or special centers selling tools. Below is a video file, after watching which you will definitely not want to get rid of the product.

Home crafts

At home, you can make a simple hand drill with your own hands from improvised means, designs and variations. We will provide several links to videos that show in detail how to make original designs.

- Drill based on mini motors:

- A mini-machine into which dental burs are inserted to make inscriptions on various surfaces at home:

- Mini-machine for polishing jewelry based on an old drill.

With your own hands

Often a moment arises when you need to make a smooth hole on some surface, but you don’t have the necessary tool at hand. Making the simplest brace with your own hands is not difficult. Knowing the principle of its operation, it will take no more than half an hour to create the design.

For manufacturing, a metal rod with a diameter slightly smaller than the size of the required hole is selected. One end of the rod is flattened in a pre-red-hot state and sharpened. For ease of use and to give an external resemblance to a brace, the resulting tool is bent in the form of a bracket. A file handle is placed on the upper end.

A handmade instrument should be heated and cooled in oil or ordinary salted water. This will harden it and protect it from rapid dulling. As a result, the brace will last a long time.

Safety and nuances when choosing

Before choosing a mechanical drill, special attention must be paid to the quality of manufacture of all visible parts, the smooth rotation of the chuck, and the comfort of the handles. There are no burrs, sharp edges or edges allowed on the housing; the gears inside the gearbox must rotate without extraneous noise.

A mechanical simple hand drill does not require any special skills to use. But there are safety requirements that are designed to minimize the possibility of injury to the worker and damage to the tool.

- Any workpiece to be drilled must be firmly fixed. If you hold it with your hands, it may break out and cause injury.

- Do not touch the drill with your hands - as a result of friction, it becomes very hot, especially in cases where metal is drilled.

- When drilling at high speeds, you need to take breaks to allow the drill to cool or apply a cooling suspension to it.

- Protect your hands with gloves and your eyes with goggles, because small drilling waste can cause injury, although the speed is not so great.

Safety measures have been developed over many years based on the analysis of incidents during work and take into account the most negative cases from practice.

Where are hand drills used?

The first human invention, with the help of which holes were manually drilled in concrete and wood, was called a brace. Based on the rotator, manual or mechanical types of drills (and later electric ones) were invented, which gained wide popularity. The rotator has the form of a curved frame, which is equipped with a chuck for fixing drills.

The rotator was not a very convenient device to use, which prompted the developers to create a hand-type drill. There is no need to go back to the past, so let’s dwell on the question of where such a device as a hand drill is now used.

Kolovorot: design of an indispensable assistant in the economy of the USSR times

The use of such drills today is no longer as relevant as it was 30 years ago, but they are still used for screwing screws and self-tapping screws. Screwdrivers are used for such purposes, but not everyone has such tools. Sometimes the power of a screwdriver is simply not enough to screw a screw into a wooden or plastic base. It is also problematic to do this with a screwdriver, so a hand-held device always comes to the rescue.

The product is also used for drilling holes with crowns. The screwdriver has little power for working with crowns, and the drill has a high rotation speed of the chuck. Drilling large holes with a hand tool, although it will take more time, will definitely not lead to breakage of the tool. The tool in question cannot be called the most necessary, but you shouldn’t rush to get rid of it either. In addition to home workshops and garages, where the tools in question are used very rarely, they also continue to be used in medicine. Without his help, it becomes simply impossible to perform operations on bone tissue and when installing knitting needles for fusion of bones.

This is interesting! Using a hand drill allows you to achieve more accurate results.

Modern look of a mechanical drill

Although electric analogues are capable of performing work tens of times faster, they do not have as much power reserve as manual products. Drilling a hole in metal with a handheld device is problematic, but making a hole in wood or concrete will not be difficult.

Drill sharpening

Dull or improperly sharpened drill bits will create a ragged, uneven surface around the edges of the hole. Therefore, it is so important to monitor the timely sharpening of tool drills.

Rotary drills

A triangular needle file is used for sharpening screw, center or variable-diameter drills. It only sharpens the inner side of the drill. The cutting side edges of the drill become sharper when the lead screw rests on a hard surface

Twist drills

Twist drills are sharpened using special electric machines into which they are inserted tip first and carefully sharpened on all sides. There are also specially created templates in which the tip is placed at the desired angle and sharpening occurs when the template is moved along the sandpaper.

Installing the drill into the brace

The safety and accuracy of the rotary work will be ensured by the use of only high-quality drills that do not have cracks or chips.

In addition to the external defect of the drill, improper fastening into the chuck will also negatively affect the result of the work, which will lead to a different size of the hole formed. To ensure proper installation of the drill bit being replaced in the brace, the ratchet ring switch is placed in the middle (neutral) position. While holding the cartridge, the handle turns clockwise. The cutting element is installed in the extended cams, after which it is clamped by them when the handle is rotated in the opposite direction.