Our company is a TENANT. The lease for office space is expiring; we are moving out after notifying everyone in advance. According to the contract, we must return the premises in the same condition in which it was leased, taking into account normal wear and tear. The landlord billed for ongoing repairs, believing that the scuff on the wall from an office chair was not normal wear and tear.

What is considered normal wear and tear in legal practice?

Return of leased property to the lessor

Upon termination of the lease agreement, the tenant is obliged to return the property to the lessor in the condition in which he received it, taking into account normal wear and tear or in the condition stipulated by the agreement.

If the tenant does not return the leased property or returns it untimely, the lessor has the right to demand payment of rent for the entire period of delay. In the event that the specified fee does not cover the losses caused to the lessor, he may demand compensation for them.

In the event that the contract provides for a penalty for untimely return of leased property, losses may be recovered in full in excess of the penalty, unless otherwise provided by the contract.

Comment on the article

1. The return of the leased property to the lessor, along with the payment of rent, is one of the main responsibilities of the tenant. The tenant is obliged to return the property in the condition in which he received it, taking into account normal wear and tear or in the condition stipulated by the contract.

The same individually defined item that was leased, together with all accessories and related documents, must be returned. The item must be returned by the tenant in the place where he received it and in the condition specified in the rental agreement. In particular, the contract may provide for the tenant's obligation to return the item after its current or major repairs or even reconstruction (renovation). If the requirements for the condition of the thing in which it must be returned are not provided for in the contract, then it must be returned in the condition in which it was transferred, taking into account normal wear and tear. In other words, the purpose of the returned item must correspond to the terms of the rental agreement or its usual purpose.

Normal wear and tear is understood as the wear and tear that the leased property would undergo during its normal use for the intended purpose specified in the contract during the term of its validity. Under any circumstances, wear and tear corresponding to depreciation standards established in accordance with current legislation should be considered normal (see Article 258 of the Tax Code). However, it must be taken into account that these standards are established mainly for fiscal purposes. And therefore the tenant is not deprived of the right to prove that normal wear and tear is actually higher.

Natural wear and tear is a completely normal and common physical process. What are its reasons? What can be said about the measurement methodology? What species diversity of this process is distinguished? These, as well as other questions, will be answered within the framework of this article.

What is a wear machine?

Car wear and tear is a quantitative measure of physical aging under the influence of external and internal factors, obtained during the operation of the car and characterizing the condition of both the entire car as a whole and its individual elements (assemblies, parts).

Interesting materials:

How to remove old paint from wooden doors? How to remove old film from windows? How to remove old tiles? How to remove old grout between tiles? How to remove super glue from wooden furniture? How to remove superglue from a case? How to remove fresh silicone? How to remove Thermal Adhesive? How to remove cracks on tiles? How to remove a scratch from a white refrigerator?

About the time factor

Natural wear and tear can also be considered from the perspective of its course. In this case, it can be continuous or emergency. Let's look at them in more detail:

- Continuous wear and tear. This is the name for a gradual decrease in the technical and economic indicators of an object, provided that proper and long-term operation is carried out. An example is mechanical wear of parts and assemblies, which affects the moving parts of mechanisms and machines. It may also affect other elements of the system.

- Emergency wear. This is the name for rapid changes that reach such proportions that the operation of the facility in the future becomes impossible. An example is a cable breakdown. By the nature of its occurrence, it can be described as instantaneous.

It should be noted that emergency wear is almost always just a consequence of hidden processes. It may be externally associated with personnel errors, discrepancies between required and available consumables, and sudden surges in supply voltage. But the hidden wear released in this case does not directly affect the technical parameters. It simply increases the likelihood of an emergency occurring.

Accounting methods

As can be seen, a wide variety of wear types can be classified and identified. Depreciation on them is calculated in several ways. This:

- reducing balance method;

- linear;

- proportional to the volume of products produced;

- by the sum of years of useful use.

All these methods are used in enterprise accounting, depending on what the company does and what volume of production it has. In the activities and life of every enterprise, great attention must be paid to wear and tear. It is thanks to the correct use of real estate and equipment, timely replacement and repair that the company receives quality goods at the least necessary costs.

We briefly reviewed wear, its types, methods of determination and accounting. Leave your comments or additions to the material.

How to influence the indicator?

Wear and tear of structures, equipment, components and parts is inevitable. But it is quite possible to extend this process. The actual value depends on the resource and service life. The first parameter is determined by the operating time, while the second is the calendar duration of operation. Usually, when creating an object, it is indicated/calculated how long it can work. For example, a car is guaranteed for 100 thousand kilometers or 5 years. But additional influence is exerted by the state of the environment, the presence of peak loads, the frequency and quality of maintenance/repair, the mode and intensity of operation. By keeping all these indicators within reasonable limits, you can achieve significant results.

Period - normal wear and tear - Great Encyclopedia of Oil and Gas, article, page 3

Period - normal wear and tear

Page 3

During the second period of operation of the cutter, when it covers the largest part of the entire cutting path, normal wear of the cutter occurs. The length of the path traveled during the period of normal wear ranges from 8,000 to 20,000 m and more. [31]

At a load of 2 tf, the normal (second) period ends when the test reaches 100 - 110 thousand revolutions of the cutter. A higher load further reduces the period of normal wear and causes intense clearance in the bearing. [32]

The wear of the abrasive grains of the grinding wheel occurs unevenly throughout the entire processing. Initially, there is increased wear, followed by a period of normal wear. At elevated conditions, self-sharpening occurs: particles break off from the grains; reduced modes lead to dulling of the grinding wheel. [33]

As studies have shown, increasing the cleanliness class and coating with a thin layer of ductile metal ensures an increase in the actual contact area and a more uniform distribution of stresses over the friction surface; an increase in hardness leads to a decrease in the depth and intensity of plastic deformation. All this significantly reduces the running-in process and significantly increases the duration of normal wear. [35]

As cutting conditions increase, tool life decreases. This reduction occurs mainly due to a reduction in the period of normal wear and tear. If the cutting mode is too high, the period of normal wear is greatly reduced and the tool life is catastrophically reduced. [36]

Thus, diagnosing the condition of a cutting tool is an urgent task of SAC, which in many existing systems is solved by monitoring the duration of the processing cycle and the total cutting time. The usefulness of time parameter control is characterized by how close to real conditions the statistical period of normal tool wear is determined and what resource value is set in the control system for each type of tool under different machining conditions. The practice of operating the SAC shows that the complexity of the dynamic system machine - fixture - tool - workpiece and the presence of many external influences on the cutting process reduce the reliability of control of the time parameter. Various types of malfunction of the cutting tool and even its breakdown most often occur by accident. Therefore, the timing control function should be considered only as an aid to ensuring reliable and high-performance machining. [38]

In Fig. Figure 3 shows the dependence of the mass wear of the steel heel disk on the duration of operation of the hydrostatic bearing. The graph shows that 60 hours of bearing operation covers only two classical wear periods: the running-in period and the normal wear period. A significant reserve of the axial size of the heel disk and thrust bearing after 60 hours of pore operation suggests its high durability. [40]

The wear pattern of parts over time is shown in Fig. 2.2. The initial value of the gap in a 6X connection is determined by the design of the connection. The wear curve can be divided into the following sections: / - the running-in period, characterized by increased wear due to the rapid destruction of microroughnesses obtained during processing of the part; II - the period of normal wear, characterized by a constant wear rate; / / / - period of emergency wear, characterized by an increase in wear rate. [41]

The wear pattern of parts over time is shown in Fig. 5.2. The initial value of the gap in the connection d is determined by the design of the connection. The wear curve can be divided into three sections: / - the running-in period, characterized by increased wear due to the rapid destruction of microroughnesses obtained during processing of the part; II - the period of normal wear, characterized by a constant wear rate; / / / - period of emergency wear, characterized by an increase in wear rate. [42]

Consequently, to determine the service life of machine parts, it is necessary to know the relationship between the operating time t of the part and the amount of its wear U. As can be seen from Fig. And, during the period of normal wear for curves a and b, there is a linear relationship between the amount of wear and wear time. [43]

As cutting conditions increase, tool life decreases. This reduction occurs mainly due to a reduction in the period of normal wear and tear. If the cutting mode is too high, the period of normal wear is greatly reduced and the tool life is catastrophically reduced. [44]

The period of operation of the tool 7 is called the period of initial wear and its value usually does not exceed 5 - 10 minutes. The rapid increase in wear during this period is explained by the running-in of the rubbing surfaces of the tool, from which the most protruding areas and the defective surface layer resulting from sharpening are torn off. The operating time of the tool from TI to T2 is called the period of normal wear. This period is approximately 90% of the total operating time of the tool between resharpenings. [45]

Pages: 1 2 3 4

www.ngpedia.ru

Normal wear and tear - Great Encyclopedia of Oil and Gas, article, page 2

Normal Wear

Page 2

Normal wear is a decrease in the performance of a machine, which occurs as a result of its long-term operation and is a consequence of friction of contacting surfaces, exposure to high temperatures and other reasons under normal operating conditions and compliance with maintenance rules. [16]

The intensity of normal wear depends on the design features of the machine or mechanism, the technological process of their manufacture, the correct choice of quality materials, the accuracy and cleanliness of the processing of the mating surfaces of the parts, the nature of the lubrication of the rubbing surfaces, the specific pressures arising during operation, the accuracy of assembly and fit of parts in accordance with specified landings, operating conditions, quality of service, timeliness7 of repairs. [17]

The process of normal wear, which occurs in the thinnest surface layers of the order of hundreds of angstroms, can be conditionally divided into three stages: 1) deformation and activation; 2) formation of secondary structures; 3) destruction of secondary structures. [18]

The period of normal wear is 90 - 95% of the total operating time of the tool before regrinding. In table 49 shows experimental data on permissible wear. [20]

In addition to normal wear, there are other reasons for tool failure, such as insufficient strength of carbide and ceramic inserts and the presence of internal stresses and cracks in them. If the operating stresses exceed the tensile strength of the tool material, then brittle fracture occurs, in which the cutting edge chips. [21]

With normal wear of the oil seal, the oil system of the sealing device is replenished once every 4 to 6 months of continuous operation of the unit. [22]

Natural or normal wear occurs during long-term operation of the machine due to friction of the mating surfaces of parts, shock loads, the influence of high temperatures and chemical effects on the material of the parts of the environment in which they operate. [23]

Next, normal wear is set to 9 microns (Fig. [24]

If we take into account only normal wear and determine it within the boundaries from 2000 to 6000 m of the track, then we get in this section and - 83 - 34 49 microns and from the south 012 3 microns. [25]

To ensure normal wear of the brake band, all rivets must be recessed to the same depth (Fig. [26]

When the period of normal wear ends, the contact surfaces of the disc and the rubber of the thrust bearing reach a state in which friction losses increase noticeably (compared to the period of normal wear by 40 - 50%) and tend to further increase. [28]

For normal wear conditions, as follows from the results of calorimetric analysis, Eq, A. In this case, heat is generated in the surface layer as a result of an elastic-oscillatory process. [29]

Pages: 1 2 3 4

www.ngpedia.ru

Evaluation Rules

Departmental building codes establish rules for assessing the physical deterioration of buildings:

- the physical deterioration of residential buildings and structures must be assessed by comparing factors identified during a visual and instrumental examination with the values given in the table of building codes;

- if a separate structural element or an entire object has signs of wear corresponding to a specific range of values, then it is necessary to take the value that is equal to the upper value of this interval;

- when only one of the signs of wear indicated in the table is found in the structure, then in this case the value should be equal to the lower limit of the interval;

- when only one sign from the table corresponds to physical wear and tear, then it should be accepted depending on the nature or size of the damage using the principle of interpolation.

It is imperative to take into account that these rules do not apply to assessing the wear and tear of residential buildings, the destruction of which occurred as a result of natural disasters.

Normal wear and tear or lease agreement to help.

You can often come across the question on the Internet: “What do you understand by the words “normal wear and tear of property” when they are used when renting non-residential premises?” It is asked by both tenants and landlords. Let's try to answer it.

The situation described on the forum: LLC “A” decided to rent out one of the offices, made repairs to it and entered into a lease agreement with LLC “B” for a year. After a year, LLC B moved out of the premises. When accepting the premises, LLC “A” discovered that the wallpaper in the room was worn and dirty, and the carpet was worn out in some places. In order to rent the premises to new tenants, it needs to be renovated again. LLC “B” refuses to compensate for the cost of repairs, citing the fact that this is normal wear and tear of the premises.

The agreement contains standard wording: “The Tenant is obliged to return the premises to the Lessor in the condition in which he received it, taking into account normal normal wear and tear.” In this regard, LLC “A” arose the question of how to determine what is considered normal wear and tear, and what can be restored at the expense of the tenant?

What is normal wear and tear

The meaning of the phrase “normal wear and tear” is not given either in the legislation or in the legal literature.

The concept of “wear and tear” is found in some acts of legislation relating to equipment wear and tear. For example, to assess the cost of aircraft, wear and tear is understood as a decrease in the value of an object (its parts) due to deterioration in its physical condition, as well as functional and economic obsolescence <*>.

In the legal literature, depreciation refers to the depreciation and physical wear and tear of long-term tangible production assets (fixed assets), such as buildings, equipment, transport, etc. <*>.

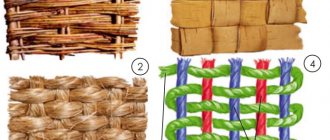

In general, we can say that wear and tear is a deterioration in the condition of an object (its part) and, as a consequence, its depreciation. This happens for many different reasons: temporary, natural, technological and economic. Based on this, three types of wear and tear are usually distinguished: physical - wear and tear of property and its parts, caused by deterioration of the original technical and operational qualities as a result of the influence of natural and climatic factors and human activity; moral - wear and tear of property and its parts, caused by the inconsistency of the characteristics of the property with modern requirements market; economic is a decrease in the value of property due to changes in external factors (environmental, economic, political, and so on).

When talking about the wear and tear of the rented premises upon its return, they most likely mean physical wear and tear. Consequently, it may be caused by the influence of natural climatic factors or human activity.

As mentioned above, which of these impacts falls under the concept of “normal wear and tear” of the premises during the rental period is not defined by law. In our opinion, this is a deterioration in the condition of the premises that the tenant could not and should not have influenced and (or) which did not occur through his fault.

Thus, the tenant cannot influence natural and climatic factors. For example, the fading of wallpaper from sunlight. As for wear and tear due to human activity, this factor is of an evaluative nature. As can be seen from the table below, not in all cases the tenant can influence the wear and tear of the premises.

| Deterioration of property caused by human influence | Note |

| The paint on the wall has peeled off (due to “old age” or poor-quality painting, etc.) | No fault of the tenant |

| The corner on the wall is knocked off | Occurred through the fault of the tenant, if there was no deterioration before the transfer of the premises |

| The linoleum is torn due to poor floor screed (there are depressions) | No fault of the tenant |

| Cut on linoleum | Occurred through the fault of the tenant, if there was no deterioration before the transfer of the premises |

| Leaks on the ceiling due to flooding on the upper floors | No fault of the tenant |

| Holes in the ceiling drilled to accommodate temporary structures | Occurred through the fault of the tenant, if there was no deterioration before the transfer of the premises |

| Worn places on the wallpaper from the backs of chairs | This deterioration is debatable |

When returning the premises to the tenant, it is advisable to analyze, together with the landlord, the reasons why each of the defects of the premises arose. In this case, it will be possible to clearly answer the question of whether this is normal wear and tear or not.

How a lease agreement can help

It is not always possible to clearly determine whether the deterioration of a room is due to normal wear and tear. As can be seen from the table, the last paragraph shows a deterioration that is controversial. On the one hand, the tenant is at fault, but on the other hand, such deterioration is inevitable. The landlord could have foreseen this and installed protective barriers for the walls. In addition, each party has its own understanding of the words “normal wear and tear,” which sometimes leads to controversial situations.

For such cases, the lease agreement can describe acceptable deterioration of the premises or what the parties include in the concept of “normal wear and tear”. Then the tenant will have to return the leased premises in the condition stipulated by the agreement <*>.

Examples of wording of the terms of the lease agreement: “The Tenant is obliged to return the Premises to the Landlord in the condition in which he received it, taking into account normal wear and tear and changes made by the Tenant agreed upon by the Landlord. By normal wear and tear, the parties understand such deterioration in the condition of the Premises that will not interfere with the further use of the Premises without the need for restorative repairs.”

“The Tenant is obliged to return the Premises to the Landlord in the condition in which he received it, taking into account normal wear and tear and changes made by the Tenant agreed upon by the Landlord. By normal wear and tear, the parties understand the deterioration of the condition of the Premises caused by natural and climatic factors, including discoloration of the walls, floors and ceilings, as well as deterioration of the Premises that did not arise through the fault of the Tenant.”

“The Tenant is obliged to return the Premises to the Lessor in the condition in which he received it, taking into account acceptable wear and tear: - floor: the color of the flooring is allowed to fade from the sun, the presence of worn places from chairs; - walls: the color of wallpaper is allowed to fade and the presence of scuffs from chairs is allowed ;— (other indicators)".

“The Tenant undertakes to vacate and hand over the rented Premises to the Lessor on the expiration date of the lease term under the Acceptance and Transfer Certificate and pay the cost of repairs if the damage was caused by the Tenant and goes beyond normal wear and tear. By normal wear and tear, the parties understand the deterioration of the condition of the Premises caused by natural and climatic conditions factors. The causes of damage are investigated by the Lessor’s technical commission together with the Lessee’s representative and are recorded in a separate report.”

How to determine the starting point of “normality”

When parties to a lease determine whether deterioration of the premises is normal wear and tear, they must actually compare the condition of the premises at the time of return with its condition before delivery to the tenant. In order for this to be realized, it is necessary to record the original state of the premises. And the more specific and complete the description of the premises is, the fewer controversial issues will arise when returning the rented premises.

When transferring the premises to the tenant, the parties sign a transfer deed or other transfer document <*>. The characteristics and disadvantages of the room can be indicated in it. But you can draw up a separate inspection report of the transferred premises.

Please note! State real estate is transferred to the tenant on the basis of a transfer deed, which must indicate (clause 7 of the Regulations on the leasing of state real estate): - place and date of drawing up the act; - registration number and date of conclusion of the lease agreement; - characteristics of the condition of the transferred real estate ;— terms and procedure for eliminating identified deficiencies and malfunctions.

For other rental objects there are no established mandatory forms of the act or a list of conditions that should be included in it. However, when drawing up a transfer document, you can take as a basis a list of conditions that must be included in the transfer deed when transferring state real estate.

In addition, the document on the transfer of premises can reflect that the real estate is transferred in proper condition, suitable for its intended use. If the property is transferred after cosmetic, current or major repairs, then it is also advisable to mention this in it.

Photographs taken during a joint inspection of the rental property before signing the deed can be attached to the transfer document. In this case, we recommend that each photo be signed by both parties to the rental agreement, indicating the details of this agreement. This is necessary so that subsequently, if a legal dispute arises, neither party can refer to the fact that the photographs were not taken at the time of transfer of property or that the photographs depict a different object.

ilex.by