Features of the operation of milling cutters

It should be immediately noted that a manual router for installation in a table is very different in its features from large stationary machines. Manual devices are particularly used in domestic conditions for processing wooden structures. With their help you can perform the following operations:

- Installation of interior structures.

- Installation of wooden windows.

- Grooving boards.

- Grinding small elements.

- Trimming excess wood.

- Making grooves and locks.

To make an error-free choice, you should understand all the functions of these devices. All of them have a huge range of options, due to which they can be used in a fairly wide range of work.

Important! They also have certain limitations. Eg:

- If it is indicated that the milling cutter should be used exclusively for point work, then it cannot be used for processing parts that are too large.

- Compact models are excellent for processing planks, boards, plywood, but massive elements are difficult to process with their help.

But it all depends on the chosen model, because there are such powerful machines that can cope with any tasks in everyday life.

Power

The more powerful the router, the more expensive it is and the more energy it consumes. This affects production costs, and ultimately the cost of production. The power is selected based on the upcoming work.

For deep sampling, up to 25 mm, the most powerful milling cutters are required, up to 2.5 kW. This limits the power capabilities of manual milling machines.

To select grooves/tenons in floor strips in large quantities and produce profile moldings (plinths, railings, etc.), powerful industrial vertical or horizontal milling cutters are used.

A low-power milling cutter (from 0.5 kW) limits the capabilities of the master. Deep sampling has to be done over several passes. During prolonged operation, a weak engine experiences overload, overheats and may fail. This option is suitable if you have to work with small items.

The best option for a small workshop is a medium-power milling cutter, from 1.1 kW to 1.5 kW.

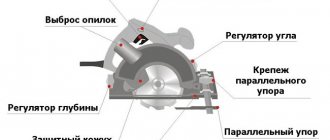

Milling cutter design

To find the best router for installation in a table for domestic use, you should clearly understand that manual models are smaller than stationary ones. Overall, they look like a large drill with additional attachments and a stabilizing bar.

The package includes the following parts:

- The engine is hidden behind a plastic or metal casing. Most manufacturers use plastic to make the casing to reduce the cost of the product.

- From the motor comes a spindle or a small chuck onto which the cutter is placed.

- There are also many milling cutters, but each of them is designed for a specific type of work. Therefore, novice masters get confused and cannot immediately choose something specific. The working attachment moves thanks to a motor, while the tool rests on a plate attached to the bottom.

- The machine is held in place by comfortable handles.

- The bottom plate protects the operator from chips, allows you to adjust the depth of cut and stabilizes the router.

As you can see, there is nothing complicated in its design, the main thing is to make the right choice, so we continue to study the devices.

What are they needed for?

To securely fix the router, there is a plate for installing it in the table. When attaching the device directly to the table, the overhang of the cutter to the thickness of the table top is lost. Therefore, a hand router is attached to a plate about 4 mm thick. The plate is fixed on the table. Its dimensions are chosen optimal to prevent deflections.

The mounting plate is a rectangular plate with a round hole in the middle. At the corners there are pins “sunk” for fastening to the table. Near the central pocket there are holes for the pins for attaching the milling device and replacement rings.

Types of wood processing devices

Choosing a router to install on a table is not an easy task, so let’s figure out what they are and how they differ. All modern models, depending on the power level, are divided into the following types:

- Lungs. Such devices have a power of up to 750 W. They are ideal for small jobs, but they are not suitable for professional use.

- Average. Their power varies between 750-900 W. This category cannot be called clear, because certain heavy varieties of milling cutters also fall into it.

Important! They are universal in the class of instruments with acceptable characteristics. They are used in particular in furniture production for the manufacture of decorative wooden elements. If you plan to use the machine at home, then focus your attention on these models.

- Heavy. They are classified as professional because they have a power of 900-1200 W. Based on the type of action, they are divided into submersible and stationary models.

Important! The most affordable fixed tool for installation in a table. It is very easy to use, but its capabilities are not very wide. The stabilizing bar in such models is not adjustable in height.

Installation

The milling plate is fixed on the selected work table (workbench):

- A rectangular hole is cut out in the tabletop. Its dimensions are 50–60 mm in length and width smaller than the dimensions of the mounting plate.

- Along the edges of the table top, recesses are selected according to the size and thickness of the slab.

- By transferring from the milling plate, the mounting holes are marked and drilled. Place the plate on the table.

- Countersunk screws from the bottom of the tabletop are secured with nuts.

- A router is attached to the plate below.

If there is no router, a blank plate is attached to the base plate and the table is used as a workbench. A hand router is not always convenient to use. To use it in a stationary milling table, industrial or homemade mounting plates are used. The manufacturing material is chosen depending on the conditions and purposes.

What types of cutters are there?

It is quite convenient to have a manual router at home, because it can significantly facilitate the performance of some household tasks. But in order to start working on the machine, to do it efficiently, you need to select and then install on it the correct shape, type and size of the cutter. Therefore, next we will talk about how to choose the best cutters for convenience and functionality.

In fact, this is an ordinary nozzle, one side of which is designed to be fixed directly into the cartridge. Its working part is located on the other side; in fact, with its help the material is processed.

Important! In order not to make a mistake, it is recommended to immediately determine for what purposes you generally need the machine. The quality of work directly depends on the type of nozzle.

They are divided into the following types:

- With guide bearing.

- With solid base.

Important! The first option involves the presence of a bearing, which slightly complicates the design. In the second case, the tool has the appearance of a solid, high-strength structure.

When should you buy with a battery?

Among the variety of manual electric routers, it is worth highlighting their battery-powered version. Due to the absence of a power cord, there is no need to keep the tool constantly plugged in and depend on the presence of current in it. This increases mobility and allows it to be used when connected to a household power supply network.

The use of cordless milling cutters will be relevant in the country, in a country house or in other places where it is not possible to power the tool from an outlet.

One of the most popular models presented on the domestic market is DeWalt DCW604N . It is used for figure milling, fitting materials and trimming wood products.

Just like the corded tools, it has a high spindle speed of 22,500 rpm, a milling depth of 55 mm and the ability to adjust the speed.

The disadvantages include the operating time, which is limited by the battery charge.

Which router should I choose for my table?

At the final stage, you need to make a choice and understand which router is best for the table:

- To perform the most basic work, you just need to purchase an inexpensive lightweight tool, since buying an expensive professional router in this case is completely inappropriate, it is a waste of money.

- If in the future you still plan to perform more serious manipulations on it, then it is better to immediately think about buying a powerful stationary unit. Apart from the choice of nozzles, no difficulties should arise.

Important! Consider ergonomics, power, equipment cost, and personal preference. Professionals do not advise buying too cheap machines from little-known manufacturers, because they believe that they will not work for a long time.

Milling to a given depth

For comparison, we forced all models to cut the following into oak blanks using the same cutters:

- nests 13 mm wide and 38 mm deep;

- three shaped profiles in one pass (with cutters for counter-profile connections and a molding cutter), as well as a fold with a cross-section of 11 x 13 mm with fast manual feed;

- figurine profile with a cutter with a diameter of 89 mm after installation in the milling table.

All models impress with their confident operation without overload when feeding manually, even if you try to do it faster than usual.

The next stage: a milling table, where a 38 mm wide figurine profile was made in three successive passes of approximately the same depth. Again, all milling machines were able to achieve a feed rate of about 3 meters per minute.

Not everyone was able to cope with the task of forming a profile in two passes. This time, only Bosch MRC23EVS (GMF 1600), Freud FT3000VCE and Triton TRA001 (all with motors over 2 kW) managed without straining.

Large router or small, fixed base or plunge-cut, you want a router that can be quickly, accurately and easily adjusted to cut holes to the required depth.

Among the models with a fixed base (included in the package), we put first the Porter-Cable model, which has an adjuster with a rack, a lock and a handwheel for coarse and fine adjustments, which are very convenient to use. Milwaukee and Ridgid also have quick adjustment mechanisms that have proven to be effective.

The fixed bases of the Craftsman and both Bosch models snap onto one of three recesses in the case. This limits the amount of movement of the collet, and if it is necessary to extend the cutter further or, conversely, reduce its overhang, you have to move the latch to another recess and unscrew or screw in the threaded adjuster again.

Convenient solution. The large threads on the Ridgid router's adjustment screw allow for quick up-and-down movement, and the locking nut helps make it even faster.

Three depth positions. The depth adjustment range of the Bosch 1617EVSPK router when fixing the protrusion in the lower recess is greater than in the other two.

Ease of control of the router is no less important than simplicity and accuracy of adjustment. Two powerful plunge routers - Freud and Triton TRA001 - are too heavy, awkward and prone to tipping over due to the large weight of the motor, which is especially noticeable when processing the edges of parts. The Bosch MRC23EVS (GMF 1600) weighs more than other fixed base models, but its low center of gravity makes it feel more manageable than larger plunge routers.

This Bosch model has one more nuance - a switch built into the handle. In other similar models, to turn it on and off, you have to release one of the handles, loosening your grip. The Bosch MRC23EVS (GMF 1600) has the same switch as specialized plunge routers, and the router is easy to operate without changing the position of your hands.

Switching modes. For plunge milling, press the center button in the handle or release it to engage the depth adjustment screw mechanism.

Which budget model worth up to 10,000 rubles to buy for your home - our choice

For home use, there is no need to purchase an expensive model with a powerful engine. A router with compact dimensions and good functionality can handle this task.

In our opinion, first of all, you should opt for the Hitman FER-800P . Its average market value is 5,913 rubles, and its functionality and reliability are at the level of well-known brands.

Fiolent MF2-620E would also be a good choice . The model is characterized by high reliability and good performance. The aluminum body perfectly resists corrosion and reliably protects the internal elements of the router from mechanical damage. In addition, its average cost is only 3148 rubles.

Speed. Cutter rotation speed

For large cutters, it is necessary to reduce the rotation speed, and for most models it is 8000-10000 rpm. But the Craftsman model has a slowest speed of 12,000 rpm. While this did not cause any problems in our testing, lower RPM is still preferred for rocks that are prone to chipping and scorching.

For Porter-Cable and Ridgid models, the regulator dial indicates the actual spindle speed. Almost as convenient are Craftsman, Freud and Milwaukee, whose nameplate allows you to easily determine the rotation speed in accordance with the digital value of the speed controller. For other routers, you will have to look in the manual to find out how the numbers on the wheel relate to the spindle speed.

Once you've set the speed you want, you want it to stay the same throughout the milling process. We measured these milling abilities using a phototachometer while milling a fig profile. In no case did the rpm drop by more than 1500; the average deceleration was only a few hundred rpm.

The Ridgid model was the most surprising, never slowing down by more than 35 rpm. This is surprising, given that its engine is the least powerful among its competitors. However, this model experienced a sharp increase in current draw during this test, resulting in an average temperature increase of 3° after each pass.

Other characteristics

The number of revolutions of the cutter is of great importance - the higher the speed, the cleaner the processing. Models of high-quality and reliable brands develop 25,000-28,000 rpm. There are models whose specifications indicate 30,000 - 33,000 rpm. You should not choose a router based on this indicator alone for the following reasons:

- revolutions over 20,000 rpm are sufficient for high-quality processing;

- winning in speed, the model loses in power due to the gear ratio (analogous to 4 and 5 gears in a car gearbox);

- extremely high speeds quickly wear out the bearings and gears of the mechanism. At the slightest imbalance in the weight of rotating parts, vibrations occur;

- the indicated record turnovers may simply be a marketing ploy to increase sales.

Optimal performance is from 20,000 to 28,000 rpm, for edge trimmers - 30,000 - 33,000 rpm.

We are talking about maximum speed. During operation, the speed can be significantly lower, as indicated in the characteristics. For example, from 11,000 rpm to 28,000 rpm.

Equipment

The Bosch MRC23EVS and Craftsman come with standard accessories that you don't have to purchase separately. The Bosch kit includes a centering cone, three connections for connecting a vacuum cleaner, three copy sleeves and an adapter for Porter-Cable standard copy sleeves.

Bosch copy bushings are only suitable for Bosch routers. They snap into a special holder. Standard Porter-Cable bushings attach with a nut to the hole in the soleplate of any router.

The Craftsman comes with three nozzles, a side support and a fixed base with a handle-bracket - a great option if you decide to install a regular fixed base in the table. All routers except the Bosch 1617EVSPK model are equipped with at least one nozzle for connecting a vacuum cleaner. True, in several models these pipes have the same diameter, and you will have to look for adapters or use tape.

Now add a couple of simple doors

1. Measure the height and width of the lower compartment and cut out two doors I, making them 3 mm lower than the height of the opening and 5 mm less than half its width (Fig. 1).

2. On each door I, use a jigsaw to cut out a semicircular cutout for the finger and sand the edges smooth. Route 3mm fillets on the front and back of the cutouts and soften the remaining edges using 120-grit sandpaper.

3. Attach hinges I to the doors, leaving 51 mm at the top and bottom. Place the case on the side wall and place the door next to it, placing pads under it. (In our case, 22 mm thick.) Inserting a 1.5 mm thick spacer between the bottom edge of door I and the bottom shelf B, attach the hinges with screws to the body (photo D).

4. In the indicated place, attach the magnetic latch plate to the door with screws and attach the latch itself to it. Then close the door and, looking into the back of the cabinet, mark where the magnetic latch touches the bottom of top shelf B. Drill holes for the screws and attach the latch to the top shelf. Now place the case on the other side and follow the same steps to install the second door.

Test results

If you can only afford to buy one router, let it be a set with interchangeable bases. The powerful Bosch MRC23EVS (GMF 1600) has proven its superiority in almost all six categories, and we give it a deservedly high rating, awarding it the title of best tool. It comes with a large set of accessories, most of which will not lie idle.

If you think this model is too expensive, take a closer look at the Ridgid R29302, a top choice for the budget-conscious woodworker. Despite the not very powerful electric motor, this router confidently copes even with increased load for a long time.

Now add a couple of simple doors

1. Measure the height and width of the lower compartment and cut out two doors I, making them 3 mm lower than the height of the opening and 5 mm less than half its width (Fig. 1).

2. On each door I, use a jigsaw to cut out a semicircular cutout for the finger and sand the edges smooth. Route 3mm fillets on the front and back of the cutouts and soften the remaining edges using 120-grit sandpaper.

3. Attach hinges I to the doors, leaving 51 mm at the top and bottom. Place the case on the side wall and place the door next to it, placing pads under it. (In our case, 22 mm thick.) Inserting a 1.5 mm thick spacer between the bottom edge of door I and the bottom shelf B, attach the hinges with screws to the body (photo D).

4. In the indicated place, attach the magnetic latch plate to the door with screws and attach the latch itself to it. Then close the door and, looking into the back of the cabinet, mark where the magnetic latch touches the bottom of top shelf B. Drill holes for the screws and attach the latch to the top shelf. Now place the case on the other side and follow the same steps to install the second door.

The best routers

Bosch GMF 1600 CE

A good multifunctional router, classified as professional. It combines traditional German quality with a high level of service and pleasant design. The motor with a rated power consumption of 1600 W, equipped with a system for maintaining constant speed and soft start, provides a head rotation speed in the range from 10 to 25 thousand rpm. The maximum immersion depth of the cutter is 76 mm, a special AfterLock system provides depth adjustment with an accuracy of 0.1 mm. Collet diameter – 12.7 mm. The router is easy to work with. Despite the significant weight for machines of this class (5.8 kg with a submersible base and 4.3 kg with a copying base), it can be easily moved over the surface being processed. LED lighting combined with a transparent base provide excellent visibility in the work area.

Of particular note is the excellent ergonomics of this router. The model kit includes:

- copying sleeves and adapters for them;

- adjustable parallel stops;

- dust extraction for plunge-cutting and copying cutters.

This router has earned a place in our ranking of the best thanks, first of all, to its wide functionality.

Existing types

Mounting plates made from:

- become;

- of stainless steel;

- aluminum;

- phenol;

- carbon;

- other durable sheet materials.

Standard plate size:

- 220x320 mm;

- 235x300 mm;

- 250x350 mm;

- thickness from 6 mm to 12 mm.

Standard replacement rings for copying bushings are available with internal diameters:

- 10 mm;

- 15 mm;

- 25 mm;

- 35 mm;

- 45 mm;

- 68 mm;

- plug ring.

Rings with additional diameters from 6 mm are produced upon request.

The main manufacturers of this auxiliary equipment:

- BLACK&DECKER.

- Bosch.

- DeWalt.

- Felisatti (Interskol).

- Makita.

- Hitachi.

- Triton.

- HAMMER.

- Kreg.

- and others.

In addition to mounting plates, mounting blocks as a whole are produced. They are capable of:

- lower and raise the drive with high precision;

- adjust the tilt of the cutters;

- perform other operations.