Gasoline saws are used in the construction of log houses, logging, clearing areas of thickets, and replenishing the supply of firewood. They allow you to effectively work with wood. The relatively simple design of a chainsaw makes it a durable and reliable tool for both domestic use and professional work. Structurally, the product belongs to the category of machines equipped with an internal combustion engine (ICE). In many cases, this is a two-stroke single-cylinder engine. The user needs knowledge of the structure of the tool and the functioning features of its individual components - this will help to carry out maintenance correctly and, if necessary, carry out repairs independently.

How does a chainsaw work?

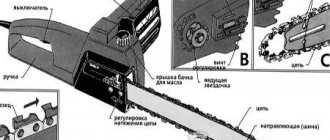

The design of a chainsaw is not too complicated. The main elements of its design:

- ignition system;

- carburetor;

- fuel system;

- air purification system.

Let's talk about each of them in more detail.

Ignition system

The ignition system of modern chainsaws contains elements that, depending on the speed of the saw, regulate the impulse. Most manufacturers today equip their equipment with electronic ignition instead of contact ignition.

The electronic ignition system consists of the following elements:

- magneto;

- candle;

- the electronic unit;

- wiring;

- motor start button.

Magneto is a type of alternating current generator. It supplies electrical energy to the spark plug. Any magneto consists of a coil with a core and high-voltage windings, a flywheel and a permanent magnet. Magneto can be contact or non-contact.

A contact magneto has two winding terminals. The first one goes to the spark plug, the second one goes to the ground. A capacitor can be connected to such a circuit to prevent the contacts from overheating and oxidizing.

In a contactless magneto, the voltage regulator is a coil. The thyristor, diode and capacitor regulate the amount of current. The electrical network operates in time with the translational movement of the cylinders and the rotation of the crankshaft. However, the connection diagram of all parts of the contactless magneto with each other depends on the model of the saw.

The ignition works like this:

- a magnet attached to the flywheel rotates with it and induces an electromotive force in the system;

- a current arises in the circuit, which is converted by an electronic unit into electrical signals;

- signals are transmitted to the candle;

- A spark is formed between the contacts of the spark plug, which ignites the fuel-air mixture.

In any ignition, a spark is formed when the engine piston does not reach its “dead center” by approximately 3-4 mm.

The spark plug consists of a body, an insulator and electrodes: central and side. By its condition, you can visually identify ignition faults.

After the fuel mixture ignites, the engine begins to operate. From time to time the entire ignition system needs to be adjusted.

Carburetor

On most chainsaw models, carburetors are designed the same.

They have a damper in the body. With its help, both screws (main and idle), diffuser, pulse channel and inlet fitting are adjusted. The damper also regulates the supply of atmospheric air.

Understanding how the carburetor works helps you adjust it correctly. It works like this:

- the engine starts, the air damper opens at the bottom of the housing;

- a vacuum occurs inside the float chamber and in the air channel because the piston moves;

- air is sucked in through the diffuser;

- the fuel mixture enters the float chamber from the gasoline tank through a fitting;

- in the diffuser, gasoline is mixed with air;

- Through the intake channels, the fuel-air mixture enters the combustion chamber.

Using the damper you can regulate the intensity of air entering the fuel, using screws you can adjust the engine speed, and using the jet you can adjust the speed of gasoline entering the diffuser.

Fuel system

Consists of a fuel filter, carburetor and manual fuel pump. However, not all chainsaws have a pump: in some models, gasoline from the tank enters the carburetor unit simply through a hose. The end of the hose with the fuel filter is immersed in gasoline, and gasoline stops flowing into the carburetor assembly when the tank is filled with air. To avoid this, a breather is attached to the tank cover: when it becomes dirty, the engine stalls.

The manual fuel pump allows you to fill the carburetor section with fuel in advance, so the engine starts faster.

Air purification system

Chainsaws are equipped with a preliminary and fine cleaning system so that the gas used to create the fuel-air mixture is of good quality.

The air is first filtered by a mesh filter, then fine filters.

Due to dirty filters, less air enters the carburetor assembly. As a result, the engine power decreases. To prevent this, filters must be constantly cleaned: blown or washed.

Starter

The starter starts the chainsaw motor. The starter mechanism consists of a handle, cable, drum and return spring.

If you sharply pull the handle with the torso, the drum will engage with the shaft, and the shaft will begin to rotate. The spring will help return the handle to its original position. In order for the rotation of the shaft to be followed by starting the motor, you will need to pull the handle more than once.

Chain

Chain pitch is the intermediate distance between three rivets located side by side.

The larger the chain pitch, the greater the engine power, its performance, and the effort required to increase the rotation of the drive sprocket.

But chains with a small pitch (more teeth and less distance between them) vibrate less, their movements are smoother when cutting, and the cut is cleaner.

Tire

Chainsaw bars vary in length. The length of the bar is the length of the working part, that is, the distance from the front of the saw to the rounded tip of the nose of the bar. As a rule, the length of the tire is indicated in the instructions.

But the reliability of the saw bar is determined not only by its own characteristics, but also by other details. For example, an asterisk. If the sprocket with replaceable ring is made of durable materials, the tire will last a long time. Thanks to the replaceable crown, the level of runout is reduced many times over.

In order for the tire to wear as evenly as possible, it needs to be turned over periodically, then its service life will increase.

Brake

If the chain accidentally touches the wood while rotating, a kickback occurs. In this case, for safety reasons, the brake must be applied.

The saw's braking system consists of a brake stop and a brake band. The system can be turned on in two ways: contact (the brake stop presses the worker’s hand) and inertial (when there is a sharp impact on the tire, inertial forces arise that act on the brake).

Chain lubrication system

In modern chainsaws, the chain and bar are automatically lubricated. At idle, there is no oil supply, since the oil pumps begin to work only after the sprocket rotates and the gear train starts moving. The higher the sprocket revolutions, the more oil flows from the pump to the chain. The pump is installed on the chain side and receives oil from the oil tank through an oil line.

Checking the ignition system

The first thing you need to do if your chainsaw breaks down is to inspect the spark plug by disconnecting the wire and carefully unscrewing it with a special wrench.

Components of the chainsaw ignition system: 1 – flywheel with magnets, 2 – ignition module, 3 – spark plug, 4 – high voltage wire

The spark plug is unscrewed to check its condition

Her appearance speaks volumes:

- Dry. Most likely, the fuel mixture is not getting into the cylinder. The problem is not in the ignition system, so the spark plug is screwed back in.

- Heavily splashed with fuel. The reason for the excess fuel mixture lies either in violation of the starting rules or in incorrect carburetor adjustment. The spark plug is thoroughly wiped, the fuel supply is turned off and the starter is turned on to remove excess fuel and ventilate the combustion chamber. Then the candle is placed in place and the mechanism is started again.

- Covered with black soot. This may indicate the use of low-quality oil, an incorrectly adjusted carburetor, or an incorrectly calculated ratio of gasoline to oil. The spark plug should be washed, removed from carbon deposits with a sharp object (an awl or a needle), the electrodes should be wiped with sandpaper and placed in place.

When checking the spark plug, you need to pay attention to the gap between the electrodes: 0.5 to 0.65 mm is considered normal. A damaged or worn gasket must be replaced.

A large amount of black carbon deposits on the spark plug indicates problems with the engine.

To be completely sure, you should also check for a spark. To do this, put the ignition cable on the spark plug, connect the spark plug nut and the cylinder with pliers, turn on the starter and watch for the appearance of a spark. If it is missing, the spark plug needs to be replaced. If the new spark plug also does not produce a spark, the problem is in the high-voltage wire or in a broken connection to the spark plug.

How to use a chainsaw

Using a chainsaw correctly is important to avoid injury hazards. The best information about the rules of operation of a chainsaw is stated in the instructions for it. The main thing is to hold the instrument firmly with both hands and all fingers.

How to start a chainsaw correctly

Before starting the chain saw, you need to engage the chain brake and remove the bar guard.

After this do the following:

- press the decompression valve control button, if equipped;

- activate the mode switch lever

- put the saw on the ground, pressing the rear handle with your right foot and grasping the front handle with your left hand;

- pull the starter handle until the engine starts;

- press the mode switch lever and press it until the saw starts working;

- Increase idle speed and release chain brake.

How to cut with a chainsaw correctly

To operate a chainsaw correctly, you need to follow the basic recommendations:

- Keeping the saw close to your body will help maintain balance.

- Spread your legs wide apart and bend your knees.

- Keep your back straight.

- Before moving to a new location, you need to turn off the engine by activating the brake.

Disposable overalls will help protect against accidental cuts. You should wear a protective helmet with a mask on your head, thick gloves for your hands, a padded suit for your body, and sturdy shoes for your feet.

Recommendations for use

To increase the life of the tool, you must follow some rules. This primarily concerns the saw chain and guide bars. It is recommended to replace the chain every three hours and turn the guides 180 degrees. As a result, these elements will wear out evenly, which will extend the life of the entire tool.

During operation, it is important to constantly monitor the cleanliness of the chainsaw. When sawing wood, the unit quickly becomes clogged with sawdust , which must be removed in a timely manner. Contamination of the technological holes can cause problems with the operation of the fuel system. It is also important to change oil and other consumables on time.

Tool preparation

A chainsaw is a motorized tool that is powered by a two-stroke internal combustion engine. It cannot run on pure gasoline, so to start it requires preparing a gasoline-oil mixture.

Its proportion is simple: for 1 liter of gasoline, grade no lower than A92 (for expensive imported chainsaws, grade no lower than A95), take 20 grams of special motor oil for chainsaws. In the instructions, this proportion is indicated as 1:50. After mixing fuel and oil in a plastic container, open the filler neck and fill the tank with the combustible mixture.

We advise beginners to be careful not to confuse the fuel neck with the neck for filling the oil that lubricates the chain. On some chainsaw models, they are both located on the same side of the body. They can be distinguished by special markings applied next to the hole. You will see a gas station icon on the fuel filler neck. A drop symbol is applied next to the oil filler neck.

Good chain lubrication is an important condition for the high-quality operation of a chainsaw and the long life of the saw bar. The chainsaw operating instructions recommend using only the manufacturer's branded oil.

In addition, it is allowed to fill in high-quality automobile engine oil with a viscosity of W30-W40. We do not recommend using dirty waste and other petroleum substitutes to lubricate the chain.

The mark up to which chain oil is poured into the tank is always located close to the filler neck. When working with a chainsaw, do not forget to periodically glance at it so as not to miss the moment of refilling the tank. In addition to the saw chain, occasionally (once a month) the bar bearing located on its outer end part should be lubricated. Some tires have a special hole there into which a few drops of oil are sprayed using a syringe. Filling the saw with fuel should only be done on a horizontal, hard surface.

Starting without a starter

Often, many home craftsmen are interested in whether it is possible to power a chainsaw without the help of a starter. The answer is very simple: this cannot be done in principle.

None of the manufacturers have provided other alternative starting methods. Therefore, even if you remove the starter and try to start the car in some other way, it still will not work, since disturbances will occur in the cooling system. This system contains a volute to transmit the flow of cold air from the flywheel impeller towards the cylinder. If it is not there, the engine will overheat and eventually seize.

Correct setting

Chainsaw and trimmer carburetor adjustment is critical for chainsaws and other two-stroke engines. An adjustment that produces a mixture that is too rich will result in the saw being underpowered, creating more carbon, and can damage the engine. Correctly tuning the carburetor will allow the equipment to produce maximum power, extend the engine duty cycle, produce minimal emissions, and operate smoothly and uninterruptedly. Most chainsaws have three carburetor mounting screws:

- Throttle stop is an adjustment that determines how much the throttle valve remains open when the throttle trigger is released. If this setting is set low, the engine will stall when the throttle trigger is released.

- Low Speed Fuel Trim (L) - Adjustment that controls fuel at idle.

- High Speed Fuel Control (H) - Controls the fuel percentage at rated operating speed. This is the most important setting.

It should be noted that some chainsaw designs do not have a high-speed adjustment needle. These saws have a so-called fixed jet, which is set by the factory. Fixed jet carburetors are used to prevent the operator from making adjustments himself, which could damage the saw. Unfortunately, these factory settings often prevent the saw from achieving maximum performance.

Fuel supply system repair

Fuel may not enter the cylinder for the following reasons:

- Fuel filter is dirty. You should remove the fuel hose and check how the fuel flows. If the stream is weak, the filter may need to be cleaned. It is taken out through the filler hole of the fuel tank and cleaned; in case of severe contamination, it is replaced with a new one. As a preventative measure, it is recommended to replace the fuel filter once every three months.

- Clogged breather (hole in the fuel tank cap). They also check by disconnecting the hose; if clogged, clean it with a needle.

- Lack or insufficient fuel. There may be several reasons for the malfunction. The first reason is a clogged air filter. Air stops flowing into the carburetor in the required quantity, and therefore, due to the fuel mixture being too rich, engine operation is disrupted. The dirty filter is carefully removed, cleaned and rinsed in water, then dried and replaced.

Another reason is incorrect carburetor adjustment. Adjustment is made with three screws.

Timely replacement of the fuel filter guarantees a complete fuel supply

The fuel hose and choke actuator must fit tightly to the fittings

The throttle cable must be in place.

During work, you must use the instructions, otherwise you can only make things worse.

And the last reason is a violation of the integrity of the membrane or clogging of the carburetor channels.

To repair a carburetor yourself, you need to become familiar with all its parts.

All parts must be clean, dry and in good working order.

Rule #2

Operating a power saw does not require special knowledge and is quite simple, but several points must be taken into account. When working with an electric saw, you should remember that the engine does not tolerate voltage surges, which often occur in the countryside or in rural areas. Therefore, experts recommend using a stabilizer.

Unlike an electric saw, operating a chainsaw requires strictly adhering to a number of rules that will ensure the correct and reliable operation of the two-stroke engine

First of all, great attention must be paid to the correct preparation of the fuel mixture. The fact is that when working with Russian chainsaws, they often use 76 gasoline and ordinary motorcycle oils, which are sold in any auto store

In this case, the oil/gasoline ratio should be 1/25. As for imported chainsaws, the manufacturer requires the use of 92 gasoline or higher, as well as branded oil, and the proportion in this case should be 1/50. Therefore, for proper and trouble-free operation of the engine, you must strictly follow the instructions. In addition, the ambient temperature is of great importance when working with a chainsaw. The fact is that at low temperatures the fuel mixture crystallizes and becomes more viscous, which in turn inevitably leads to a decrease in the quality of the mixture itself. Therefore, working with a chainsaw in winter requires the operator to provide the possibility of heating the carburetor or store the saw in a heated room. It should also be remembered that the fuel mixture loses its quality during long-term storage (more than 1 month). Therefore, it is better to use a freshly prepared mixture and drain the remaining fuel that remains in the tank.

Adjusting the chain brake

The chain brake often does not work due to grease or sawdust clogging the brake band and the space under the cover. All parts should be cleared of blockages. Perhaps the tape is simply worn out, then it needs to be replaced.

The operation of the chain brake is restored by mechanical cleaning

Some parts of a chainsaw wear out faster than others. These include the drive sprocket, tire, chain, and anti-vibration elements. For quick replacement, it is better to always have spare parts on hand. Don't neglect sharpening the chain.

Chainsaws help to quickly and efficiently clear a space of trees, build log houses, or prepare wood raw materials. But in order to work with this tool correctly and safely, it is useful to know what is inside it.

Signs of engine trouble

Maintenance or repair of the motor should be carried out in the following cases:

- The engine will not start;

- The engine stalls almost immediately;

- Unstable work;

- Loss of power and stalling under load.

Disassembling and cleaning the muffler

If the engine runs great at low speeds, but starts to stall at high speeds, the reason may lie in the muffler spark arrester, which is clogged with combustion products.

- remove the muffler;

- disassemble (there are also non-dismountable models);

- remove carbon deposits using detergents;

- dry with a hairdryer;

- install in place.

Dry cleaning is unacceptable, as carbon deposits contain carcinogens, the inhalation of which is hazardous to health. After removing the muffler, cover the exhaust hole with a clean rag.