A vice is an indispensable partner for any master. Various configurations of this tool allow you to clamp workpieces and parts, significantly reducing labor costs and increasing safety during operation.

In order to learn how to use a vice, you do not need any special skills, but the question remains of how to choose a high-quality and reliable tool among the variety of models on the market.

Parallel vice

This most common type of clamping device is used when processing parts made of wood, metal, plastic and other materials. Fixation of the workpiece is ensured by two parallel surfaces.

One of the identical parts, called jaws, slides towards the other, with a tight fit to the workpiece, fixed in the desired position. The movement of the bench vice is ensured by a manual drive and a lead screw.

Configurations and Mountings

The lower part of the base of the rotary type vice is equipped with a plate with a vertical axis, which is fixed on the workbench and allows the tool to be used in various positions.

Non-rotating models are fixed and used in one position; their design, with the same dimensions, provides the greatest width and opening of the jaws

According to the type of fastening, there are stationary vices, equipped with a base plate with holes or claws for screws, and portable ones, which are fixed on the workbench using suction cups or clamps. There are also special models with a weighted frame that do not require fasteners.

The best vices for machine tools

This category of tools has larger sizes and is designed for fixing to the working surface of machines (milling, cutting, drilling). The vice is designed to securely hold workpieces so that the powerful rotations of the machines do not tear out the product. The equipment, as a rule, has an executive part (cutter or drill) that is stationary or has a small sideways movement.

In order not to move the vice to the left or right when working with workpieces of different sizes, such devices are equipped with longitudinal and transverse stroke. They are used in factories and workshops where machine tools are operated.

| Wilton 11693RU | Proma KS-100 | Blacksmith WA1-100 | WILTON Q75 75x80 mm WI91193RU | |||||||

| Lip width, mm | 75 | 100 | 90 | 75 | ||||||

| Weight, kg | 7,5 | 9,7 | 12 | 1,95 | ||||||

| Working stroke, mm | 80 | 102 | 100 | 80 | ||||||

| Rotate function | ||||||||||

Wilton 11693RU

Product from an American manufacturer. Belongs to the category of professional vice. Has a lip divergence of 80 mm with a grip width of 75 mm. In addition to the transverse stroke of the working clamping part, a center shift is provided, and there is also a longitudinal stroke.

+ Pros Wilton 11693RU

- To unfasten the vice and reinstall it in another place, it is not necessary to unscrew the bolts completely - just loosen them and remove them from the grooves.

- There are vertical and horizontal slots on the lips so that thin objects do not move (pins, wire rod) and are firmly held in a clamped position.

- Ball stops at the ends of the handles.

- There is a scale with divisions for precise adjustment.

- High-quality assembly without play.

- Good painting without drips on the working moving area.

- Supplied with three hexagons for assembly and adjustment.

— Cons of Wilton 11693RU

- Wide internal parts do not allow fixing a large part vertically - this limit is limited by the lip height of 35 mm.

- No anvil or rotation function.

- Heavy (7.5 kg), therefore suitable only for stationary use.

- The cast handles for moving the body do not sit completely on the axle - they are hampered by edges that need to be filed with a file (factory defects).

- Tight move.

Conclusion. This is a good machine vice for alternating both manual processing of parts and for securing in a milling machine. For this purpose, grooves are provided in the base, which can be fixed to a workbench or machine platform. Suitable for small production, where precision execution is important and assembly is carried out according to drawings.

Proma KS-100

A vice from a Czech manufacturer with a working stroke of 102 mm and a jaw width of 100 mm. They are equipped with a stroke for longitudinal and transverse transmission of 127 mm, which makes them maneuverable and simplifies work at the machine.

+ Pros of Proma KS-100

- Access to screws for easy lubrication.

- The forward, backward and sideways strokes have stops, so nothing will fall apart if the operator turns the handle all the way.

- High-quality paint without drips.

- The chrome-plated handles are pleasant to the touch, protected from corrosion, and the L-shape is more convenient for regular rotation.

- There is a tightness setting to select the desired mode for different types of work (adjustable with screws located perpendicular to the shaft).

- Removable lips for longer use of the vice itself.

- To rearrange it on the frame (if there is not enough travel to bring the part in), it is enough to loosen the clamping bolts and remove them through the slots in the vice body.

— Cons of Proma KS-100

- The first installation is not the easiest due to the weight of 9.7 kg.

- The open shaft system gives quick access to chips.

- When working on a milling machine and pouring a cooling emulsion over the part, the body becomes corroded faster.

- The design of the vice is designed for installation in a drilling machine with the side of the jaws facing the vertical stand, but this makes it difficult to fasten long parts (they rest against the stand). When the body is turned 90 degrees, the tightening handle begins to rest against the rack—an additional adaptation device is needed.

Conclusion. This is a reliable vice for a drilling machine, because it is assembled with very high quality and is precisely adjusted on the sides with the workpiece already clamped. With their help, you will be able to drill holes according to strictly specified parameters with a minimum error.

Blacksmith WA1-100

A special vice, working on the principle of a clamp, for fitting parts together at an angle of 90 degrees. Can be used on profile pipes and plates. They have a working stroke of 100 mm and a jaw width of 90 mm.

+ Pros of Blacksmith WA1-100

- The walking part swings on an axis with a stop, which ensures uniform distribution of the pressing force, alignment of the workpieces and easy removal of the already welded structure.

- The screw is copper plated and protected from corrosion.

- There are long grooves on the base for fastening in the machine - you can move the vice to the side by loosening the bolts, and not by completely unscrewing the fasteners.

- Durable metal frame.

- The guaranteed 90-degree position eliminates the need to check the workpieces with a square during assembly.

- They come with a preservative lubricant.

— Cons of Blacksmith WA1-100

- Thin and uncomfortable handle.

- Moving from machine to machine is not easy - the weight is 12 kg.

- Vibration on the machine can cause the bolt of the moving handle to come loose - you need to put a rubber band under it.

- The fixed stop cannot be replaced - it is part of the body, and the internal stop is expensive.

Conclusion. This is a good vise-clamp for use on a milling machine or drilling holes in workpieces assembled at an angle of 90 degrees (safe frames, brackets for installing air conditioners, etc.). Thanks to the vice, it will be convenient to simultaneously clamp the product, drill it and weld it.

WILTON Q75 75x80 mm WI91193RU

A budget vise model from an American brand, assembled in China. It has a stroke of 80 mm and a jaw width of 75 mm. For mounting on the frame, there are four long grooves that facilitate lateral mixing.

+ Pros WILTON Q75 75x80 mm WI91193RU

- High quality durable cast iron.

- The stainless steel shaft tolerates water and other coolants well.

- The handle is also made of stainless steel and has a rotating mechanism, ensuring compactness and tightening in a comfortable position for the operator.

- Lips can be replaced.

- The moving part has a hinge between the shaft and the lip that aligns the part before clamping.

- The screw rotates without jamming.

— Cons WILTON Q75 75x80 mm WI91193RU

- The height of the jaws is only 19 mm - you won’t be able to grip very large objects.

- There is no rotation function.

- There is a noticeable play in the handle and vertical play in the movable lip.

- A spacer is needed between the bed and the vice, because on some models the rotary handle touches the workbench.

- The lower surface of the moving part is painted, and underneath it lies a poor finish - you have to additionally sand it for easy operation.

- The steel plate has sharp burrs that require grinding down.

Conclusion. This is one of the simplest vices to use on a machine tool. Suitable for router or drilling machine. But the lack of quick adjustment for longitudinal and transverse stroke allows them to be used where the same workpieces are involved and frequent changes in dimensions are not required.

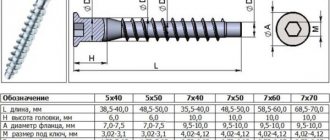

Dimensions of bench vise

The operating parameters of the vice are determined by the width and maximum extension distance. Another indicator is the clamping force, which directly depends on the weight and dimensions of the model and is indicated in the product passport in units of kilogram-force (kgf).

The three-dimensional dimensions of the vice (width, height, length) determine the required working space for using the tool. Weight range – from 4 to 60 kg. There are also lighter, compact models for household use.

The presence of an additional surface on the vise body - an anvil, such as in the photo, will optimize the work process.

What are the different sizes and weights of vices?

The weight of a vice depends on its dimensions - as the size increases, the weight also increases. It is also related to the material of the base, bed and jaws. Here are the three main categories of vises:

- Small - length and width no more than 29x14 cm with a stroke of the working part of 80 mm. The weight of the vice does not exceed 8 kg.

- Medium - the jaws expand up to 125 mm, and the dimensions are 37x18 cm. The weight reaches 14 kg.

- Large jaws are capable of fixing parts with a width of up to 160 mm, and the dimensions of the vice are 45.8x22 cm. The weight of the device is up to 30 kg. Due to their large size and heavy weight, they are used only in specialized industries and workshops.

Selection options

Depending on the specifics of the planned work, the compression mode is selected - point or rough. The pitch length of the clamping mechanism depends on the thread of the lead screw.

The surface of the sponges can be grooved or smooth. The choice of one model or another is determined by the texture of the workpieces being processed. A dot or grid pattern improves adhesion but may leave undesirable marks, such as on wood parts.

Models with the same dimensions may differ in size and configuration (that is, the ratio of length, width and height) of the jaws.

The strength of the steel alloy from which the tool is made is an important indicator of quality. Due to the nature of the application of force, the characteristics of the material are the main criterion for the reliability of carpentry vices, therefore, when purchasing them, you should not save money by purchasing non-certified products.