Why does the Shtil chainsaw not start?

To pre-diagnose the causes, check the operation of the fuel pump, the appearance of the spark plug, the flow of fuel, the functionality of the carburetor and the condition of the filter. Pay attention to the performance of the cylinders, pistons, muffler, and crankshaft bearings. After preventive measures, they try to start the chainsaw. Insufficient lubrication of rubbing parts also becomes a factor in poor performance.

In this article, we will look at the main problems that may arise when starting a Shtil chainsaw (the spark is lost, the tool stalls or does not pick up speed), as well as ways to eliminate them.

No spark

The spark on the spark plug is checked. The functioning of an element is influenced by various factors. When testing the mechanism, the reasons are revealed:

- insufficient carburetor adjustment;

- large oil in gasoline;

- clogged fuel and air filters.

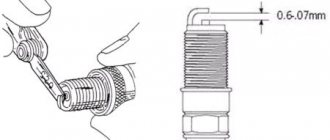

Due to working in such conditions, carbon deposits accumulate on the spark plug contacts. Subsequent corrosion of the conductors becomes the reason that there is no spark in half of the cases of malfunctions. This happens because the gap between the modular contacts changes. To check the spark do the following:

- the tip of the high-voltage cable is removed;

- the candle is unscrewed;

- the tip is put in place;

- the candle is leaned with its wide end against the cylinder;

- start the starter.

If during startup a bright spark resembling lightning appears between the electrodes, then the ignition unit is working. If there is no flash, clean the entire element and adjust the gap between the conductors. Sometimes there is no clearance between the flywheel and the ignition coil. When the flywheel rubs, scratches are visible on its exterior.

Ignition coil malfunction

The module or coil cannot be disassembled; its suitability is difficult to determine without testing devices. Modern ignition systems are durable, lightweight and small in size. They are characterized by almost trouble-free functionality. Problems with a chainsaw malfunctioning due to the ignition coil can be resolved independently.

The outlet wires are tested for damage (including internal damage) that occurs due to vibration leading to friction. If no cracks are detected, then the ignition coil needs to be replaced. Sometimes a module malfunction is indicated by a weak, barely visible flash when the saw heats up. This occurs due to an increase in the temperature of the coil, which leads to an increase in the resistance of the transistor.

The peculiarity is that at the beginning of operation a spark may appear, but after prolonged use it becomes dim and disappears. Modern ignition coils cannot be repaired in a home workshop, so they are replaced with suitable elements.

Fuel supply

After unscrewing the spark plug, a wet coating is found on its surface. This indicates an excessive supply of gasoline to the combustion chamber. For this reason, the tool does not work or stalls, because the fuel does not ignite.

Another inhibitory factor is a clogged breather - a small hole in the gas tank cap. It is cleaned with a needle, otherwise the Stihl MS 180 chainsaw will not start. To determine the incorrect fuel supply, the following steps are carried out:

- remove the candle;

- pour 2 cubes of gasoline into the hole of the candle with a syringe;

- put the ignition device in place and put on the high-voltage wire cap;

- the lever is moved to the hot start position;

- pull the starter handle a couple of times.

If the tool starts and immediately stalls, then the fuel line is tested further. Check the gasoline filter, splashes from the engine crankcase, and the integrity of the partition in the pump when unscrewing the cap.

Crankshaft bearing failure

If the bearings are defective, a slight play is felt. To identify it, the flywheel of the Stihl MS 180 saw is swayed from one side to the other. The movement indicates that the flywheel is being moved towards the electrodes by its own magnets, as a result of which there is no spark. To remove the mechanism, dismantle the cutting element, remove the filter and clutch cover. To lock the crankshaft, remove the recoil starter cover and tighten the two bolts.

The clutch is unscrewed clockwise using the key. Remove the drum with the sprocket, replace the old clutch and tighten it until it stops. The crankshaft is locked so as not to break the starter. The mechanism is assembled in the reverse order. To tighten, the brake handle is tilted forward, the tool is wound in, and then removed from the brake.

Bearings with defects are less often detected (the diameter of the holes in the cage is increased). To determine, disassemble and measure using a micrometer. Broken bearings are indicated by regular knocking noises. In this case, urgent repairs are required, because if the integrity of the crankshaft is damaged, the piston group and cylinder will fail.

Floods the spark plug

In this case, the spark is not able to ignite the fuel, which enters in large quantities into the firebox to burn the combustible mixture. If the spark plug is flooded, then the carburetor is faulty or the cold engine does not start correctly. The engine is purged; the procedure is performed with the ignition off and away from open flames. To ensure fuel ignition at the time of start-up, clean the mechanism:

- unscrew the candle, wipe it dry, let it dry for half an hour;

- a large layer of carbon deposits is removed with a file;

- the gap between the contacts is adjusted;

- turn the tool upside down and drain the gasoline;

- in this position, pull the starter several times (to remove residual fuel);

- Reassemble in reverse order.

What to do

The power tool is operated according to the manufacturer's instructions. Only after checking the chain tension does the unit start. At the same time, the filling of the tanks with combustible mixture and oil is controlled, and the device is securely fixed in the hands. If, after following all the rules, the mechanism refuses to work, then the Shtil chainsaw is repaired.

How to start a Shtil chainsaw correctly: instructions

The tool manufacturer has taken every precaution and developed a manual that makes it easy to start the mechanism. The user will protect himself from injury if he follows the suggested frequency of actions:

- The ignition is turned on and the engine handle is placed in the down position. The flow of atmosphere from the air filter is blocked by the carburetor damper. To properly start a chainsaw, the throttle membrane must be open to enrich the combustible mixture.

- The lever is set to the start gas position. The starter jerks several times before the first spark appears. If the flash passes, the instrument is ready to start. The mechanism operates at high speeds due to the closed throttle membrane. To transfer it to the idle speed regulation, the throttle trigger is pressed and immediately released. The number of revolutions quickly returns to normal.

- The standard Shtil MS unit does not provide additional devices to start the chainsaw in the lightweight version.

Idle speed adjustment

Before setting up, carry out maintenance of the tool. To ensure that the idle speed adjustment is effective, preventive measures are taken:

- carburetor cleaning;

- engine flushing;

- cleaning the air filter;

- warming up the engine.

To adjust the operation of the mechanism at idle speed, use the appropriate adjusting screw. Its rotation depends on the required setting:

- During standard adjustment, the screw is turned counterclockwise until it turns tightly. After this, make 2 circles in the direction of the arrow.

- If the saw operates at low speeds, then turn the screw clockwise until the chain begins to move. Then make half a circle in the opposite direction.

- At high frequencies, the regulator is turned counterclockwise until the circuit stops. After this, the rotation is continued another half turn in the same direction.

It will not be possible to adjust the idle speed if there is air leakage into the engine through the gasket, acceleration pump, seals, or for another reason.

Ignition settings

Gasoline engines are equipped with an ignition system that ignites the fuel. The timing of the flash affects the operation of the motor. During mass production in factory conditions, the ignition of the chainsaw is not adjusted. Marks are placed on the corresponding rotating elements, which are aligned during adjustment. Incorrect adjustment leads to the mechanism starting and stalling.

Before adjustment, check the dryness of the spark plug and the functionality of the ignition circuit. The voltage supply cable to the spark plug is brought to the cylinder with a small gap and the starter is started. If there is no flash, test the cable with a probe. Then check the serviceability of the wire to the shutdown button.

If the cables are not damaged, then check the ignition coil. This is done with a special tester to ring the device. In this case, the indicators on the device must coincide with the technical characteristics of the coil, which are specified in the instructions for use. If inconsistencies are detected, the ignition unit is replaced with a functional device.

The reel can become unusable due to vibration when the tool is dropped or hit, so you need to work carefully.

Replacing crankshaft bearings

First, they measure the compression; if it is not there, then the reason lies in the breakdown of the piston group.

The required pressure in the cylinder should be 8 atm; if it is lower, then the cylinder and piston, rings, and crankshaft bearings may have worn out.

To find out the condition of the piston system, you need to completely disassemble the saw and remove all the main components of the mechanism:

- dismantle the headset, remove the cover on the bus;

- remove the tire guide and tool chain using the wrench included in the kit;

- remove the air filter, remove the spark plug;

- a piston stopper is attached in place of the spark plug to secure the crankshaft;

- remove the clutch, then access to the clutch system is opened.

Rings with bearings are inspected and defects are identified. You can replace it yourself, which will require repair skills, or you can take the tool to a specialized workshop. Assembly is done in reverse order.

Checking the muffler

Most likely, the reason lies in the muffler, which is clogged with combustion products (deposits) or simply debris. It is enough to clean it, and normal operation of the chainsaw will be restored. To do this, it is best to dismantle this part and wash it using ordinary detergents (aggressive ones are possible). Then rinse the muffler thoroughly with clean water and dry it with a hairdryer.

Cleaning the muffler usually has a positive effect

When cleaning, be careful: carbon deposits contain carcinogenic substances that, if they enter the lungs, can be harmful to health. The reason for the appearance of carbon deposits is the incorrect ratio of gasoline and oil poured into the tank. Most users prefer to do this “by eye”. But maintaining the exact proportions is not at all difficult: just use a disposable syringe without a needle of the appropriate volume.

General information

The characteristics of this saw are a source of pride for the German manufacturer. At the same time, the unit is a tool that is designed to perform a small amount of work. The tool is positioned for domestic use, which confirms the intensity of its use, which should not exceed 20 hours per month . Having such a unit at your disposal, it will not be difficult for you to maintain order in your garden, prepare firewood for the winter, and also clear areas. At the same time, he will be able to help you in solving other problems where there is no need to perform complex manipulations.

Main characteristics

The saw in question can be considered a compact option, because its weight is only 3.9 kg. At the same time, it has a large capacity oil and fuel tank. The device performs its operating functions using a two-stroke engine, the power of which is sufficient to solve simple tasks. In addition to this, during operation this tool does not create much noise, the level of which does not exceed 98 dB . For ease of understanding, it is enough to say that human speech creates noise at a level of 76 dB.

- The Stihl 180 chainsaw has a power of 2.6 watts. In principle, this is enough, remembering that we are talking about a tool for household use.

- The capacity of the oil tank is 0.145 l, the fuel tank is 0.25 l.

- The tire provided by the design has dimensions of 350 mm, with a pitch of 0.325 inches.

Winding device

As with other saws, the carburetor plays the role of the main starting device. Looking in more detail at the carburetor that the Stihl 180 chainsaw is equipped with, it should be noted that it has a single adjustment screw. In other words, it is a kind of idle adjustment screw . In this case, the jet, which bears the full load, is motionless all the time.

In other words, the regulation is not applicable to him. In turn, there is no way to influence the full load in any way. You also need to pay attention to the factory settings, due to which the air-fuel mixture is supplied directly to the engine. Moreover, this principle remains unchanged regardless of the operating conditions of the tool.

Specifications

The Shtil 250 chainsaw is supplied as standard to the Russian market with two tires of different lengths: 14 and 16 inches. Depending on the task at hand, you can choose any one, with luxury versions such as Shtil MS 250

When choosing a chainsaw, you should not focus too much on the length of the bar; if necessary, the bar and chain can be replaced with a longer one, or vice versa, after purchase.

| Manufacturer | Stihl |

| Model | MS 250 |

| Homeland of the brand | Germany |

| Country of Origin | China |

| Saw class | Semi-professional |

| Engine | |

| Power, hp/kW | 3,1/2,3 |

| Engine capacity, cc. | 45,4 |

| Saw set | |

| Tire length, cm/inches | 40/16 |

| Chain pitch, inches | 3/8 |

| Chain thickness, mm | 1,3 |

| Number of links, pcs | 55 |

| General characteristics | |

| Fuel tank volume, l | 0,47 |

| Oil tank volume, l | 0,2 |

| Warranty, months | 12 |

| Weight, kg | 4,6 |

| How much does it cost, price in rubles | 24 990 |

The weight of the chainsaw is indicated without refueling fluids. Of course, it’s difficult to determine from the characteristics how a chainsaw will behave in practice; to do this, you need to try it at work and compare it with something. To find out how much a chainsaw costs today, we suggest looking at the most current offers from Yandex.Market:

Characteristics of modification C-BE

Due to the presence of a quick chain tension system, the weight of the saw is increased by 0.3 kg and amounts to 4.9 kg. The cost of the improved modification will be approximately 10% higher. Today the current price is 26,990 rubles. All other technical characteristics of the standard and improved model Stihl MS 250 C-BE are the same. Power 3.1 l. s., which translates into 2.3 kW. By the way, this is 0.8 more than the household model Stihl MS 180. Engine speed is 11 - 13 thousand.

Consequences of running an engine with untuned fuel equipment

The traction characteristics of the engine and the duration of its service life depend on the composition of the mixture.

- Working on a lean mixture initiates a drop in power, overheating of the cylinder and intense wear of loaded parts and components of the chainsaw.

- Working with a rich mixture is no less dangerous. The malfunction is manifested by an increase in the time it takes to reach operating speeds, increased fuel consumption, and smoke from the muffler.

- There is also intense formation of carbon deposits in the combustion chamber and loss of mobility of the piston rings.

Required special tools for repair

Before repairing a STIHL chainsaw, you need to prepare the necessary set of tools. A chainsaw is not a complex piece of equipment at a technical level; its assembly and disassembly are quite common working tools that every man has on the farm. But since the chainsaw comes from Germany, and the Germans are very pedantic people, there is a special STIHL tool for more comfortable repairs.

The STIHL multi-tool is made of high-quality hardened steel in a housing made of impact-resistant polymer. The tool is very convenient and small in size. It contains screwdrivers: a 3.50 mm slot for cleaning the carburetor grooves and adjusting it, a Torx TX27 screwdriver.

Depending on the combination key model (0000 890 3401 or 129 890 3401), the tool has a set of spark plug keys from 16.19, respectively. The unique, functional STIHL comes in a durable nylon pouch with belt clip.

Chainsaw Stihl 180 does not start: causes and repairs

And the world famous company Stihl produces a huge range of high-quality chainsaws. Stihl chainsaw was created for household purposes and simple work.

180, which showed excellent performance and reliability. All the best practices of the German company were used here; weighing 3.9 kg, the chainsaw easily performed work in the garden. It’s easy to cut small trees and branches from it, you can even prepare firewood. But any, even the highest quality equipment, as a rule, fails, and it happens that the Stihl 180 chainsaw will not start and does not start with great difficulty. We tried to collect all the reasons and methods for repairing the German Stihl 180.

STIHL MS 250 C-BE

For even greater customer comfort, STIHL produces models equipped with an improved modification. Their letter designation can be deciphered by knowing what each specific letter means.

(E) – a starter with a special spring is installed on the saw, which reduces the load when starting the STIHL 250 chainsaw, making the start smooth and comfortable. The system is called ElastoStart.

(B) – the saw is equipped with a chain tensioning system without the use of additional tools. Thanks to which, the operator does not need to carry tools with him. And this is quite convenient.

(C) - means that the saw has modified gas and oil tank caps. It is not difficult to open such lids, but they have no chance of unscrewing on their own, as happens with ordinary lids.

Winding device

Related Posts

The basis of this type of model, as well as all other chainsaws, is the carburetor. But since we are talking today specifically about the Shtil 180 chainsaw, we will not deviate from the topic. So. The carburetor in this model has a single adjustment screw , that is, it is a kind of idle speed adjustment screw. While the jet of the fully loaded load is stationary.

Chainsaw carburetor Stihl 180

KEY-DOP

In simple terms, we can say that it simply cannot be adjusted (see here), while the full load setting simply cannot be changed. It is important that the carburetor itself was configured at the factory in such a way that, regardless of the conditions under which the chainsaw is directly operated, the air-fuel mixture is supplied to the engine itself.

The choice between the 250th and 260th Shtil model

Readers have many questions about the choice between Shtil 250 and 260 chainsaws.

The answer can be unequivocal. The Shtil 260 saw is better for the reason that it is a saw for professional use and, during production, completely different requirements were placed on it than the Shtil 250, intended for agriculture.

Accordingly, the cost of these models has a significant difference. Shtil 260 is sold at almost 50% more expensive than Shtil 250. Of course, for those who don’t mind paying for a professional tool and using it in private households, it’s definitely better to buy Shtil 260, but the 250 also lasts for many years and practically does not kill if done in a timely manner. THAT and normal attitude.

We recommend reading an interesting, detailed review of the Stihl MS 260 chainsaw.

Algorithm for determining the causes of poor mixture formation

In any case, a wet spark plug on a chainsaw indicates a clear imbalance in the composition of the air-fuel emulsion. Already at a fuel to air ratio of 1:14, the conditions for spark formation worsen; the lack of air prevents the normal combustion of the fuel-air emulsion compressed in the combustion chamber.

The main reasons for over-enrichment of the mixture in most cases are standard:

- air intake filter clogged;

- incorrect carburetor adjustment;

- interruptions in the operation of the ignition system;

- It is also possible that the quality of gasoline is poor and that the starting sequence of the power unit is not correct.

How to start a chainsaw correctly - follow the instructions

Before you move on to studying the causes and repairs of chainsaw malfunctions, you need to understand whether you are starting to work with your chainsaw correctly. After all, it is precisely because the tool is not started correctly that its engine stalls or does not start at all.

Start the chainsaw strictly according to the instructions in the operating instructions. The procedure is as follows:

- First, engage the chainsaw's chain brake by pushing its lever away from you;

- Remove the protective cover from the tool tire;

- Press the decompression valve, if provided in the design of the chainsaw. This will make starting the engine much easier;

- If the design of the chainsaw includes a fuel pump for manual pumping, press it several times;

- Place the combination throttle lever in cold start mode. To do this, lock the throttle trigger and lower the lever to its lowest position;

- Place the saw on a flat surface, removing any foreign objects from under its bar;

- Hold the chainsaw with both hands, placing your left hand on the handle and your right hand grasping the trigger cable. Place the toe of your right foot into the “eye” at the back of the chainsaw;

- Slowly pull the cable towards you until you feel resistance. Then quickly pull the cable towards you several times until you hear the motor start briefly;

- Move the throttle lever to the middle position;

- Pull the cable again several times until the engine starts;

- As soon as the engine starts running, sharply press the gas trigger and hold it for several seconds. At this time, move the throttle lever to its highest position;

- Raise the saw from the ground without touching the gas lever;

- Pull the chain brake handle towards you;

- Raise the saw over old newspaper to make sure there is oil flowing to the chain. If small spots of oil appear on the paper, then you can start working.

https://youtube.com/watch?v=mB_j_KfjGZw

Chainsaw Shtil stalls: reasons

If the tool turns off immediately after starting, it means that some device or part has broken down. To determine the cause, the mechanism is tested independently or in service workshops. Sometimes the reason that the mechanism does not start well is improper maintenance of the saw:

- insufficient amount of gasoline;

- poorly prepared fuel mixture;

- poor quality of lubricant;

- muffler clogged with combustion products;

- unadjusted carburetor;

- obstruction of the air filter;

- piston or cylinder failure.

When you press the gas

The sawing units operate at idle speed, but the chain saw stalls when the gas is pressed, as the load increases. Before use, warm up the tool by running the engine at idle speed for a minute. If this is neglected, the motor stops after pressing the pedal. Other reasons may be:

- clogged or unregulated fuel mixing unit;

- a clogged air filter does not provide the required air flow when the load increases;

- a dirty gasoline filter does not allow the required amount of mixture to pass through;

- the cylinder and piston walls rub.

A low octane number of fuel causes brakes, since this circumstance prevents the engine from achieving the required power when the load increases.

At idle

Violation of the functionality of the fuel unit system leads to air leaks. In this case, the unit stalls at idle and does not maintain its number. Additional suction reduces the air impulse to the fuel pump and passes through the sump membrane or crankshaft seals. Diagnostics is done with a vacuum gauge.

Stopping the engine when cold occurs for other reasons:

- the spark plug channel contains an excess amount of combustible mixture;

- the gap between the tip of the spark plug and the high-voltage cradle is not adjusted;

- power supply failure.

Check the seals by pouring gasoline into the crankcase; the leak is visible visually. This means that the engine does not operate at idle speed, and at high frequencies, leaky oil seals will lead to bearing jamming. If elements leak, they are replaced with new ones and sealed.

Full speed ahead

Sometimes the engine stalls after normal operation. To establish the cause, pay attention to the accompanying circumstances:

- The engine stalls in the middle of operation for no apparent reason. The starter is in a stationary position and does not turn. This means that the tool is jammed and requires urgent repair.

- During normal operation, power decreases in a short time and the engine stops, the cylinders are overheated. The situation indicates an air leak under the rubber pipe between the carburetor cylinder, possibly due to a rupture. The air becomes depleted of fuel; the pipe needs to be replaced.

Not gaining momentum

Many mechanism systems are involved in the startup, so the loss of speed of the Stihl chainsaw after idling can be a consequence of various factors. Reliable idling and interruptions in the engine under load can occur for the following reasons:

- development of engine life;

- wear, deformation and corrosion of the piston group;

- malfunction of the ignition coil or spark plug;

- unbalance of carburetor screws.

If the tool does not develop speed, then the conductivity of the hole in the fuel tank cap is impaired. The occurrence of a vacuum does not provide the required amount of fuel, so the engine does not gain the required power. The speed decreases when carbon dioxide accumulates in the muffler, and the removal of combustion gases is difficult.

Doesn't slow down

The tool quickly reaches maximum speed without losing power. This situation is explained by the fact that:

- the throttle valve does not work due to a weakened spring or traction element;

- the switch on switch periodically fails;

- there is no corkscrew on the throttle axis;

- the carburetor is clogged;

- The fuel hose and gasoline filter are not functioning properly.

Troubleshooting carburetor

If, as a result of pressure on the gas, the chainsaw begins to stall, then the problem lies in the carburetor. Also, a sign of a carburetor malfunction can be a prolonged start of the chainsaw and the inability to gain speed.

Most often, this malfunction occurs as a result of wear of the rubber cuff, which is located on the fuel accelerator piston. As a result, air leaks when starting the tool. Basically, such a breakdown occurs after several years of using the chainsaw.

Elimination of this malfunction is carried out in the following sequence:

- Remove the carburetor. Unscrew the screw that holds the cover with the membrane. Turn the carburetor so that the pin is visible. You need to remove the retaining ring from it and disconnect the air damper spring. After that the throttle valve. To do this, you need to unscrew the screw that holds it in place. The next step is to remove the damper shaft.

- Pull out the accelerator with the spring. It has a cuff on it. Wear of this particular element leads to air leaks and engine shutdown after a recent start. The piston and cuff need to be replaced.

- Reassemble the carburetor in reverse order and install it on the chainsaw.

Step-by-step disassembly of the carburetor

This is interesting: if you don’t have a spare accelerator at hand or it’s impossible to purchase one in a store, then you can use an alternative repair option. In this case, a plug is installed instead of the piston. This will prevent air leaks. After such repairs, the chainsaw will work properly. The difference will be that it will take a little longer to launch.

Now we know how to fix common carburetor malfunctions. If you follow all the rules, you can easily do this work with your own hands.

You may also be interested in an article on how to choose the right chainsaw.

Our next article talks about how to repair a Partner 350 chainsaw.

Other reasons

Here, first of all, we mean wear of the cylinder, piston, rings, and crankshaft bearings. The failure of these elements ultimately leads to a drop in compression (pressure) in the cylinder. You can check the condition of the CPG at the same time when you remove the muffler. After dismantling this part, you will see a window through which part of the cylinder is visible. If nicks or scratches are visible on it, it will have to be replaced.

Parts for repair can be purchased in specialty stores or on the Internet.

Next you need to check the compression. If you do not have a special tool, remove the spark plug, plug the hole with your finger and pull the starter cord. With good pressure, the finger will be sucked inside. If you have a compression gauge, you need to insert it into the spark plug hole. Also crank the crankshaft using the starter and look at the instrument readings. The normal parameter is 8-9 kgf/sq. cm (which corresponds to 0.8-0.9 MPa). The reason for low compression may not necessarily be a worn cylinder or piston: sometimes it is enough to replace coked rings.

- Author: Yuri

Rate this article: (9 votes, average: 3.8 out of 5)

Diagnostics of exhaust channels

Clogged exhaust channels or their mufflers are another non-obvious reason for a chainsaw not working. In addition to problems with starting, clogged channels manifest themselves in a decrease in the power of the tool. Exhaust channels are susceptible to accumulation of tar deposits. They focus on spark arrestors or muffler ducts. The reason for the formation of these deposits is the use of low-quality gasoline or oil. These components prevent the tool from venting exhaust gases.

Repairing the exhaust channels is easy for the owner of the saw to handle on his own. The only difficulty is the depth of this part. To get to it, you need to have a good understanding of the structure of the saw.

The instructions consist of several steps:

- The muffler is removed (to do this you will need to unscrew the screws).

- The cooling plate and mechanical seal are removed.

- The spark arrestor is removed.

- The resonator body is disassembled.

- The elements are washed from carbon deposits using a cleaning solution.

- The elements are thoroughly dried.

- The saw is going back.

During disassembly, it is easy to be careless and allow sand to get into the cylinder. To prevent this from happening, it is important to first cover the engine exhaust port with a sterile cloth.

Return under warranty and post-warranty service

Chainsaw maintenance includes:

- Monitor the quality of gasoline and oil on the basis of which you prepare the fuel mixture. Stick to the correct proportions when doing this;

- Do not use fuel prepared more than two weeks ago. Regularly check and clean the gasoline and oil tanks, otherwise the engine will stall or the saw will not start at all;

Chainsaw chain maintenance

- Clean the air filter regularly. It has a simple device and this operation will not require much effort from you;

- Turn the bar over every time after the next sharpening of the chain - this will extend the service life of the saw set;

- Regularly check and thoroughly clean the oil inlet and outlet ports, oil channel and guide bar groove. Remember that if the automatic lubrication system is faulty, your saw will start or stall;

Your main assistant should be the instruction manual. If you have lost it, you can contact the dealer of the company whose chainsaw you use; they will provide you with instructions in electronic form.

So, before each time you turn on a gasoline chain saw, be sure to check that the chain is in good condition, whether its teeth are sharpened, and whether it is well tensioned (does not sag, but is not too tight, it can be pulled a little away from the blade).

You can sharpen the chain using a special machine or a file with a special template (depending on the tooth pitch of the chain, there are different templates).

Every time after use, the chainsaw must be cleaned: the chain, bar, air filter, housing, cooling fins, cracks and other grooves are cleaned of sawdust. After using the saw, turn the bar over so that it wears evenly, lubricate the sprocket (if there are grooves for lubrication in the front of the saw).

During long-term storage, be sure to drain the fuel and oil! The chain and the bus form an electrochemical pair, so they rust together and must be stored separately.

To sum it up...

Equipment breakdown is undoubtedly a very unpleasant and upsetting incident for its owner. But don’t despair ahead of time, because if your chainsaw needs to be repaired, it’s just a matter of time. In this article, you were able to familiarize yourself with the most common problems regarding chainsaw malfunctions, as well as options for eliminating them at home.

The most important thing is that if you want your tool to always be in working order, and there are no problems with its operation, just keep an eye on the equipment . Often look directly into its “inner” area. Maybe some part will wear out soon, maybe something needs to be cleaned, etc. Read how to sharpen a chain with your own hands

In fact, this kind of manipulation is not complicated and can be done periodically. But this is a “plus” for you, first of all, since a breakdown will not catch you at the most inopportune moment, when you need to do a huge amount of work and you will not have to waste time solving problems associated with the breakdown.

We also recommend that you familiarize yourself with the Swiss company that produces Husqvarna chainsaws.

If you still haven't found what you need after viewing these articles. then we suggest looking at the article “chainsaw friendship technical characteristics”.

Starting without a starter

Often, many home craftsmen are interested in whether it is possible to power a chainsaw without the help of a starter. The answer is very simple: this cannot be done in principle. None of the manufacturers have provided other alternative starting methods. Therefore, even if you remove the starter and try to start the car in some other way, it still will not work, since disturbances will occur in the cooling system. This system contains a volute to transmit the flow of cold air from the flywheel impeller towards the cylinder. If it is not there, the engine will overheat and eventually seize.

There is a spark, the spark plug is wet

First of all, it is necessary to remove the muffler and carefully inspect the piston, since this is where the problem may be hidden. but the chainsaw still does not start or stalls, the saw does not start, Partner 350. In addition, most owners wonder: why does the chainsaw start and stall, while there are supposedly no problems with the spark plugs?

But this is an erroneous opinion and you don’t need to be so sure in this case, as there are situations when the candle sparks perfectly in air, but does not work directly in the cylinder.

The reason for this may be a direct violation of a kind of compaction in the canal area (impulsive). Or so there is a peculiar development of crankshaft oil seals, but this feature occurs in very rare cases.

The Shtil ms 660 chainsaw is the most economical of the entire Shtil chainsaw line. Its price ranges from 3,100 to 5,500 rubles.

Basic configuration, equipment, country of assembly and production

The basic package of the stihl 660-ms saw includes:

- saw part (represented by a chain, sprocket and bar);

- chainsaw body with engine and fuel tank;

- owner's instructions;

- warranty document, usually found in the manual for the technical device;

- chain saw chain tension screw.

On the domestic garden equipment market you can often find analogues or counterfeits of the stihl 660-ms chainsaw model, the documentation for which indicates the country of origin is China. Note that the Chinese analogue of the original Shtil 660-ms chainsaw is not the original. However, taking into account the reviews of the owners of such “copies”, it can be noted that the Chinese copy is quite suitable for everyday use.